A key component of any laser cutting system is the laser cutting head. Choosing the right laser cutting head can significantly impact the quality, speed, and cost effectiveness of your operation.Choosing the right laser cutting head is crucial for ensuring optimal performance and efficiency of your laser cutting machine.

In this blog, we’ll explore the key factors to consider when choosing a laser cutting head for your application.I hope it will be helpful for you to choose the appropriate fiber laser cutter head.

What is fiber laser cutting head?

The laser cutting head is the core component of the metal fiber laser cutting machine. It is a laser output device, which consists of a nozzle, a focusing lens and a focus tracking system.

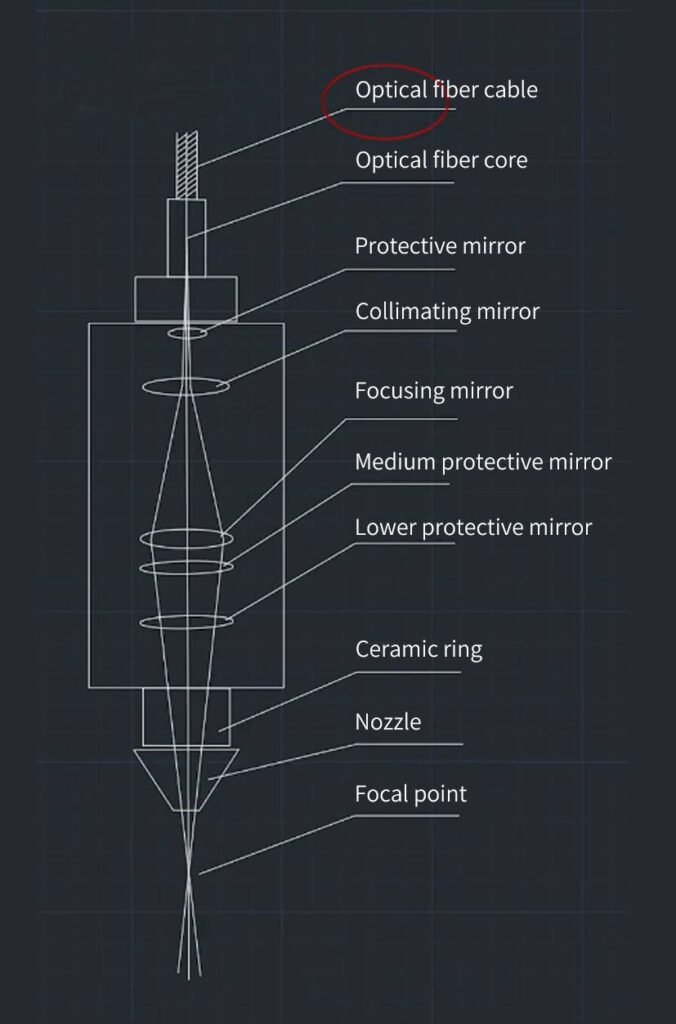

CNC laser cutter head mainly include 10 parts: optical fiber line, optical core, upper protective lens, collimating lens group, focusing lens group, middle protective lens, lower protective lens, ceramic body, nozzle, and focus。

Types of Laser Cutting Heads

Laser cutting heads come in various types, each designed for specific applications. The most common types include:

CO2 Laser Cutting Heads

- Ideal for: Non-metal materials such as wood, acrylic, glass, and certain plastics.

- Advantages: High power output, capable of cutting thicker materials, excellent edge quality.

- Disadvantages: Larger and more complex, requiring regular maintenance and gas refills.

Fiber Laser Cutting Heads

- Ideal for: Metals, including stainless steel, carbon steel, aluminum, and brass.

- Advantages: High efficiency, low maintenance, compact size, and faster cutting speeds for thin materials.

- Disadvantages: Higher initial cost, less effective for non-metal materials.

Diode Laser Cutting Heads

- Ideal for: Engraving and cutting thin materials.

- Advantages: Compact, energy-efficient, low cost.

- Disadvantages: Limited to lower power applications, not suitable for thick materials.

CNC laser cutting heads installation tutorial

Many customers do not know whether to choose an auto-focus laser cutting machine or a manual laser cutting head when purchasing laser cutting equipment.

The laser cutter head is one of the important components of the laser cutting machine, it is very important in the cutting process,The metal cutting laser head seriously affects the cutting accuracy and cutting speed.

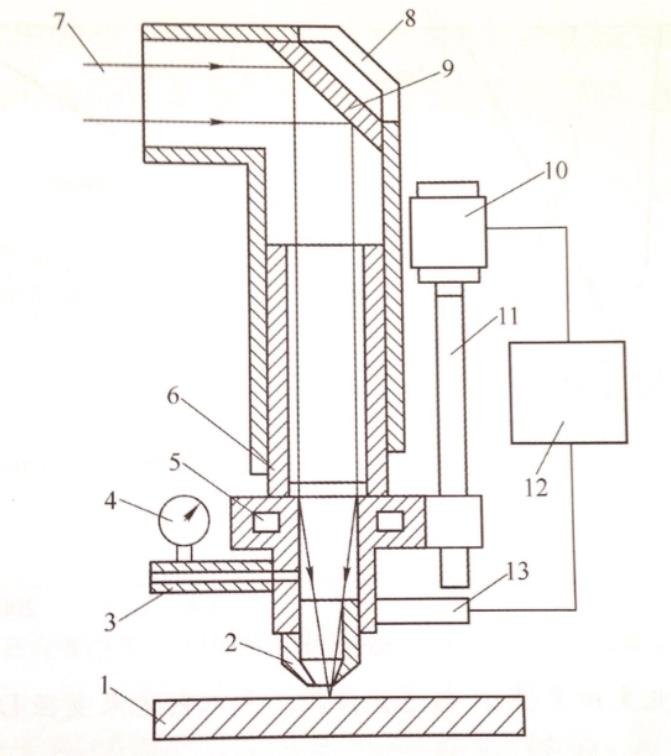

Fiber Laser cutting heads structure diagram

- artifact

- nozzle

- Oxygen intake pipe

- Nitrogen pressure gauge

- Lens cooling water jacket

- focusing lens

- Laser beam

- Reflector cooling water jacket

- Reflector

- servo motor

- ball screw

- Amplification control and drive motor

- position sensor

focus bm110 raytools fiber laser cutting head

Depending on the thickness of the cutting plate, the laser cutter head requires different power of the laser, and the price of the high-power laser cutting head is relatively higher. When choosing an industrial laser cutting machine, customers should not only consider the price, but also the quality and speed of cutting carbon steel plates.

Laser cutting heads are generally used for cutting metal sheets such as stainless steel, carbon steel, brass, aluminum sheets, etc. The requirements for laser cutting heads are relatively higher, and higher melting points require high-power laser cutting heads.

The thicker the metal sheet, the higher the laser power required. For thin sheets with low power, it is recommended to use a laser cutting head less than 3000w. In addition, a suitable laser head should be selected according to the thickness of the sheet to be cut, and the cutting effect is satisfactory.

Best laser cutting head for CNC Brand

IPG fiber laser head

The components of the laser cutting machine cutting head are: nozzle, focusing lens and focus tracking system.

The cutting head has a focusing shaping part, which can make the light spot energy higher during industrial processing and improve processing efficiency. And according to the actual processing scene, the laser spot shape and processing depth can be adjusted when outputting light

Raytools Laser Cutting Head

Quality. The raw materials of Heijingang laser cutting head are imported from Germany, with high craftsmanship and good quality.

In terms of price. Compared with other brands of cutting heads, Heijingang fiber laser head is more economical and cost-effective. Heijingang fiber laser head is better.

Precitec Fiber Laser Head

With auto-focus system, high-speed operation, simple and intelligent operation, flexible design, and fast cutting.

Generally, the 1000w-3000w laser cutting head for cnc on the market can meet the cutting of metal sheet.

There are many laser cutting head manufacturers on the market for you to choose from, such as: ipg laser cutting head, raytools fiber laser head, precitec fiber laser cutting head, if you want to buy cheap fiber laser cutting head price, it is best to go to the manufacturer for field inspection Look, compare several metal cutting laser head factories.

What are the components of laser cutting head

- Fiber optic cable

- Optical core

- Upper protective mirror

- Collimating lens

- Focusing lens

- Medium protective mirror

- Lower protective mirror

- Ceramic ring

- Nozzle

- Focus lens

- Led light

- 19pin interface pin pin

Fiber optic cable

The optical fiber interface beam is transmitted by the optical fiber line. This part is an important part of the optical fiber connection to the cutting head. The beam enters the cutting head and reaches the surface of the plate.

optical core

Laser transmission medium. The diameter of the optical core is very small, including 30 mil, 50 mil, 100 mil, and 150 mil. In international units, one millimeter is equal to 1000 millimeters. We often hear that 50 millimeters is equal to 0.05 millimeters, which means that laser light is transmitted through a 0.05 millimeter optical fiber.

Upper protective mirror

Very thin lenses are relatively cheap. Their main function is to prevent dust from entering the inside of the cutting head and protect the collimator lens. Because collimating lenses are expensive.

Collimating lens

The collimating mirror has a convex surface that produces refraction. Collimating lens position The collimating lens is equivalent to a convex lens. Divergent light is incident and parallel light is emitted, converting the divergent light beam transmitted in the optical fiber into parallel light. The light output by the optical fiber itself is divergent, so it needs to be collimated and then focused. If the spot is small, it must be expanded and then focused.

Focusing lens

To focus the laser light, most cutting heads change the focus by moving the focusing lens up and down. Focusing lenses are also very expensive lenses.

The function of the focusing lens is to use a convex lens to focus the parallel light beam into a focal point and act on the material being cut to melt and cut it.

Medium protective mirror

This one is cheap and has the same price as the protective lens. Its main function is to protect the focusing lens and act as a seal.

In order to protect the focusing lens, the protective lens is designed, which saves the cost of the laser equipment during the processing process.

Lower protective mirror

It prevents iron slag from returning upward during perforation and cutting, and isolates the cutting gas.

ceramic ring

There are metal wires inside the ceramic ring that connect the nozzle to the sensor and transmit the nozzle sensing data. In addition, the ceramic ring is fragile. In the event of a serious collision, the ceramic ring will be damaged first to protect the cutting head.

Comparing the original and non-original ones, Prezite’s original ceramic ring is made of oxidized aluminum. Compared with alumina, it is denser, wear-resistant, has a small thermal expansion coefficient, and has a high resistivity. It is polished after molding and has a high surface finish. , after such ceramics are bonded to stainless steel, they are not easily deformed

Nozzle

Both the laser and the cutting gas pass through the nozzle, and the cutting quality and speed of different nozzles are different. The nozzle is the most common consumable part on the laser cutting machine, and it is also one of the most important parts

It is located at the bottom of the laser head and is closest to the workpiece. The focused laser and high-pressure airflow are ejected through the nozzle. The material must have high electrical conductivity and good thermal conductivity. Generally, nozzles made of copper are better than those made of brass and can ensure a good capacitive signal.

Focus lens

The intersection of the concentrated light is the place where the laser energy is most concentrated. When cutting different plates and using different focal points, fiber lasers are very sensitive to dust. Any lens failure will affect the cutting quality and speed.

LED light

You can view the internal conditions of the cutting head in real time through these 4 lights, such as lens temperature, focus position, etc

19pin interface PIN pin

A metal substance used in connectors to complete the conduction (transmission) of electricity (signals). PIN pins are high-precision products, with tolerance requirements of ±0.001-±0.0005.