The new handheld laser welding machine is a new type of high-tech equipment that is well known and widely used in the metal processing industry. How to buy cheapest laser welder is a question that many people are concerned about.

The new generation of handheld welding torch head replaces the previous fixed optical path, which is flexible and convenient and can be used to achieve outdoor welding and long-distance welding machine according to the space of the site.The handheld laser welding device, used to directly fix the laser welding device for proximity welding, favourably reduces the size of the laser welding device, is easy to operate, easy to weld, fast and favourably improves welding operability.

The handheld laser welder for sale market has an endless array of prices, and I hope this article will help you to select the affordable welders.

What is a laser welding machine

Laser welders, also often called handheld fiber laser welders and metal laser welders, are machines used for laser material processing.

Laser welding uses high energy laser pulses to locally heat the material in tiny areas. The energy from the laser radiation spreads to the interior of the material through heat conduction, melting the material and forming a specific molten pool for the purpose of welding.

How do laser welding work

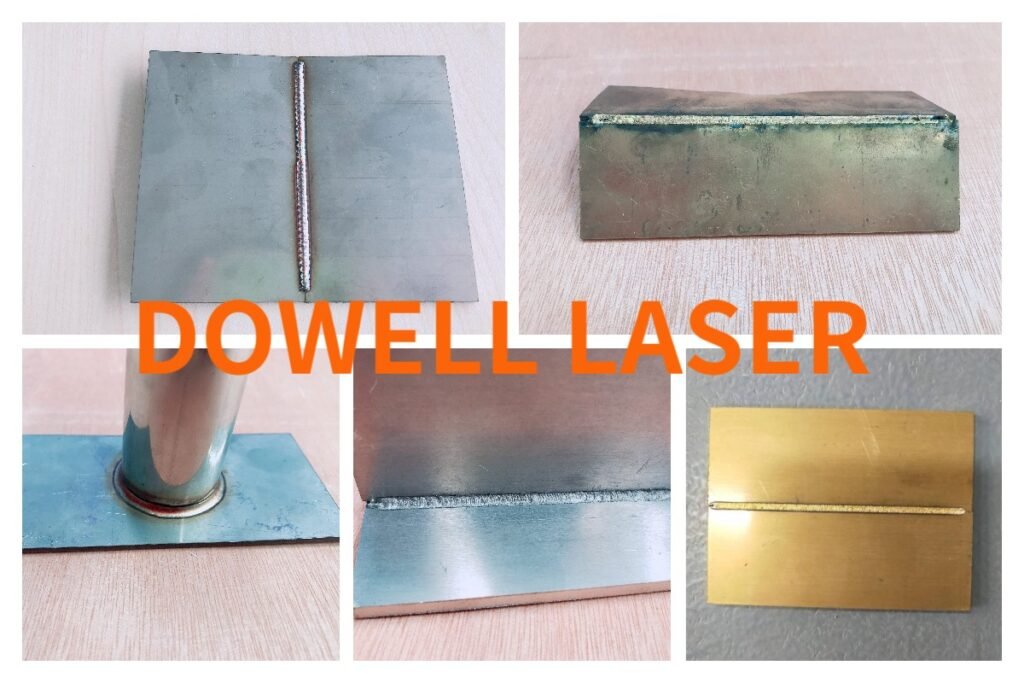

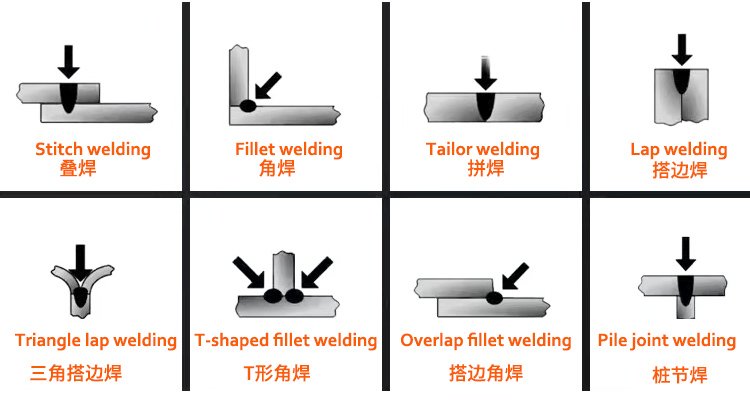

Hand held laser welders, with handheld welding guns instead of the previous fixed optical path, hand-held welding, flexible and convenient, longer welding distances, overcoming the limitations of the workbench space, workpieces can not be automatically welded when the size is not uniform. Mainly for large workpieces, fixed positions such as internal right angles, external right angles, flat welding seam welding. It is a new and more flexible welding process for welding large workpieces from a distance. Effective welding of carbon steel, stainless steel, galvanised sheet metal and other metal materials, suitable for sputtering, stack welding, internal and external fillet welding, circular arc welding, irregular shape welding.

How much does a laser welder cost

2023 handheld laser welding cost on the market vary from $7,850.00 to $9,420.00 for the lightweld 1500 laser welding system and from $7,850.00 to $13,345.00 for the handheld laser welding machine. Air cooled handheld laser welder price $15,000.00.

The Handheld Laser Welder Price is expensive, and the difference is so large, mainly depends on the configuration of the welding machine.

Why laser welding cost is expensive

Because the thickness of the metal sheet you want to weld is different, the required fiber laser welder power is different, the nozzle of the laser welding torch and the required handheld laser welding machine with wire filling system are different, and each handheld fiber laser welding machine suppliers chooses Different lasers and water coolers, which also lead to different laser welder prices, so if you want to buy cheapest laser welding machine, you need to carefully investigate some welding machine manufacturers.

What are the types of handheld fiber laser welder?

Laser welding machines are also often called welder lasers, energy negative feedback laser welding machines, fiber laser welders, laser weld machines, laser cold welding machines, laser argon welding machines, laser welding equipment, etc.

According to the way they work they can often be divided into laser mould burners (manual laser welding equipment), high power aluminium laser welders, laser welding handhelds, lightweld 1500 laser welding system, laser welding machine portable,continuous laser welding , vibrating mirror laser welding machines, automatic laser welding machines, jewellery laser welding machines, compound laser welding machines, robot laser welding machines, laser spot welding machine, fiber optic transmission laser welding machine, laser welding and marking machine, etc.

Laser welding machines can be divided into, if they have a laser source, fibre lasers, CO2 lasers and YAG lasers. Each of these laser sources has its own benefits and is suitable for different types of welding materials

Specialized laser welding equipment include sensor welding machine, silicon steel sheet laser welding equipment, keyboard laser welding equipment. The laser welding machines can be used to weld points, lines, circles, squares or any flat shapes drawn by the software.

Composition of fiber laser welder

Handheld laser welding machine generally consists of laser, water chiller, control software, laser welding head, optical fiber and other components.

What are laser welding materials?

Fiber laser welding can weld carbon steel, die steel, alloy steel, stainless steel, titanium, nickel, tin, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, as well as steel, Kovar and other alloys The welding between the same material can also meet the laser welding between different steel materials.

Is laser welding safety

Fiber welder machine Because the laser light produced by the light laser can cause damage to the eyes, wear laser protective glasses or a protective mask on the belt, and take personal safety protection measures.

The application of hand held fiber laser welder industry

Suitable for stainless steel, carbon steel, silicon steel, copper, aluminum alloy, gold, silver, chromium, nickel, titanium, tantalum and other metals or alloys, but also for a variety of dissimilar materials between the welding. Widely used in precision instruments and meters, electronic components, home appliances, medical equipment, mobile phone communication, mobile phone parts, computer shells, sinks, stainless steel kitchen products, vacuum insulation cups, sensors, mold accessories, safes, distribution boxes, stainless steel products, aluminum products, copper products, alloy materials, watches and glasses, jewellery, hardware components and other industries.

Scenarios in which industrial laser welding can be used.

Almost all the materials used in the industrial industry in the current market are suitable for handheld laser welding

1. laser welding of sheet metal, chassis and water tanks.

2. laser welding of various types of hardware lamp type.

3. laser welding of door and window frames.

4. laser sealing welding of kitchen and bathroom, washbasin hardware.

5. Laser welding of billboards and advertising letters.

6 light sources for cheap laser welder

- spot welding: small spot, strong energy, spot welding mode can be used when there is a requirement to weld through or cut through the material

- linear welding: adjustable width, certain penetration of the material after comparison, linear welding mode can be used in sputtering, wire feed welding, positive corner welding.

- Type “0” welding: adjustable diameter and uniform energy density distribution; type “0” welding can be used for high frequency welding of thin plates.

- Double “0”: adjustable diameter, its main function is to reduce the spot and it is suitable for welding at various angles.

- Triangle welding: adjustable in width, the energy of the 3 sides can be fully heated in the middle and on both sides of the plate while reducing the spot.

- “8” welding: on the basis of the triangle continue to increase the spot, so that the plate repeatedly heated, large width welding can be used “8” welding mode.

Application of hand held laser welder advantages

- 1. Handheld welding torch replaces the previous inherent optical path, more flexible and convenient to achieve long-distance laser welding, overcoming the limitations of the bench travel space.

- 2. Handheld welding head equipped with 5m-10M original optical fiber, flexible and convenient, can realize outdoor welding;

- 3. Hand-held operation mode, equipped with special welding nozzle can achieve any part of the workpiece welding at any angle;

- 4. Matching a variety of laser sources, suitable for a variety of process requirements workpiece, welding once formed, basically no deformation, to meet the requirements of high-quality products.

- 5. Beautiful weld seam, no welding scars, no discoloration, no need for subsequent polishing.

- 6. Solid welding, the strength of the weld meets or exceeds that of the base material itself.

- 7. Suitable for spiral welding, stack welding, internal and external fillet welding, circular arc welding, irregular shape welding, etc.

- 8. The whole set of equipment is highly functional and ergonomically designed for various working environment scenarios.

- 9. Proprietary laser safety operation protection function, to ensure the safety of the operator during work.

- 10. Simple and easy to learn to operate, with a low technical threshold for the operator, saving labour costs.

- 11. Some of the welding equipment uses an integrated cabinet, integrating the laser, chiller, software control, etc., which has the unique advantages of small footprint, easy to move, and strong functionality.

Advantages and disadvantages of fiber laser welder

- Easy to start: handheld fiber laser welding machine operation with less than professional welding knowledge, only need about 1 hour with the technical staff to understand the relevant training, you can start to complete the welding.

- Efficiency is improved: the product welding speed, saving human capital, is several times the argon arc welding.

- No consumption of materials: handheld laser welding machine configuration automatic wire feeder, in welding without filling the wire to complete the welding work.

- Good effect: small welding influence area, no deformation, firm welding, high depth to width ratio.

- High energy efficiency conversion: the laser photoelectric conversion efficiency of up to 30%, lower energy consumption.

- Flexible use: handheld fiber laser welding machine, can be moved to achieve outdoor welding, easy to use, flexible placement.

- No grinding of the weld seam: continuous welding mode, beautiful welding without scars, less subsequent grinding process.

- The disadvantage is that long-term use may lead to arm soreness and a few sparks when welding, it is recommended to equip goggles during operation.

FAQ about cheapest laser welder

Is ndustrial laser welder with wire feed expensive

The cost of laser welding equipment depends on the power, the laser, the thickness of the welding plate is different, and the price is also different.

Where to buy cheapest laser welder

If you want to buy cheapest laser welder, you can find relevant supplier exporter laser welder review on Alibaba, Amazon, or Aliexpress to compare prices.

If the pre-budget laser welding equipment cost is limited, you can consider buying a used laser welder, but you should know that such equipment accessories welding gun or laser may have problems at any time, so it cannot be used for a long time.

Is laser welder rental reliable?

This is possible, the early handheld laser welder price is more expensive, and the budget is limited, you can consider leasing, which can save more costs. Compared with the used laser welding equipment, the performance is more stable, safer and more efficient.

How much power is used for 0.5mm aluminum laser welding?

If the weld seam is less than 0.3 mm, you can choose 1000W laser weld aluminum, and the hand-held welding without wire feeding can achieve the welding effect.

After welding with wire feeding, there will be bumps, and subsequent polishing is required. You can use a wire feeding handheld welding machine. If the thickness of the material is less than 1mm, it is recommended to use 1000W handheld welding without wire feeding, because the wire feeding welding speed will be relatively slower. And it is easy to deform.