How to cut copper pipe is a headache for many novices in copper pipes. Many customers have asked us more than once if we have the fastest way to cut copper pipe and how to cut copper pipe close to wall. We are cutting batches in the industrial market. Copper pipe is cut differently than if you didn’t have a copper pipe cutter at home. This article will give you the key points.

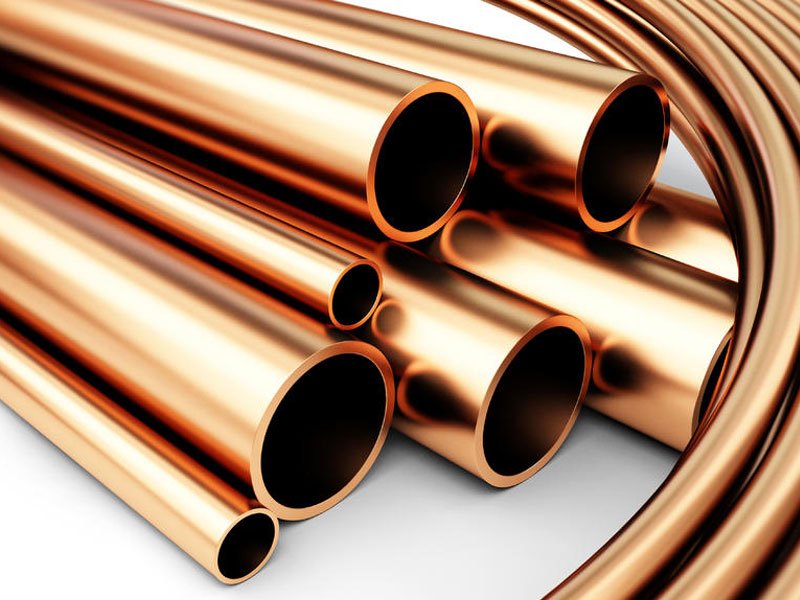

What is copper pipe

Pipes made of copper offer excellent thermal and electrical conductivity, corrosion resistance, strength, ductility and temperature resistance. Light weight. Copper products gradually expanded to red copper, brass and white copper.

Types of copper pipes

Copper pipes can be divided into various types such as seamless copper pipes, welded copper pipes and spiral copper pipes.

Seamless copper tube

Made of cold or hot rolling, the surface is smooth and the inner and outer diameters have high dimensional accuracy. It has corrosion resistance and is generally used in the manufacture of high-precision instruments and heat transfer equipment.

Welding copper pipe

Copper strips or copper plates are made by processing, bending and welding. Compared with seamless copper pipes, welded copper pipes have rougher inner and outer surfaces and slightly lower dimensional accuracy.

Welded copper pipes are easy to use and cost-effective. They are often used in various types of low-pressure pipelines and industrial cooling equipment.

Spiral copper tube

Also known as spiral seam pipe, it is processed using advanced technology, with smooth internal and external surfaces and high dimensional accuracy.

Spiral copper tubes have larger wall thickness and strong pressure resistance, and are often used in the manufacture of steel coolers and various heat transfer equipment.

Copper pipe specifications

Specifications and models of seamless copper pipes, welded copper pipes and spiral copper pipes. Different specifications and models are suitable for different occasions, and you should choose according to the specific needs when selecting.

| Type | Specifications (mm) | Models |

|---|---|---|

| Seamless Copper Pipe | 4-80 | T1, TU1, TU2 |

| Welded Copper Pipe | 6-60 | T2, TP1, TP2 |

| Spiral Copper Pipe | 30-200 | T2, TU1, TU2 |

Features of copper pipes

Different types of copper pipes have different advantages and characteristics in use.

Seamless copper tube

It has the characteristics of wear resistance, corrosion resistance, high temperature resistance, good pressure, and high thermal conductivity. It is often used to manufacture high-precision instruments and mechanical equipment as well as various types of heat transfer equipment.

Welding copper pipe

It has low cost and is easy to use. It is often used in low-pressure pipelines and industrial cooling equipment. However, the corrosion resistance and pressure resistance of welded copper pipes are relatively poor, so attention needs to be paid to its use environment and pipeline design.

Spiral copper tube

It has strong pressure resistance, large wall thickness, high flow capacity, and smooth internal and external surfaces. It is often used in high-pressure heat transfer equipment and other occasions.

Copper tubing sizes

European standard copper fittings are available in sizes 6-108 mm. Availability varies based on the specific type of accessory.

US standard copper fittings are available in sizes sie 1/4″ to 6*. Availability varies depending on the specific type of fitting.

Copper pipe use

Copper is used in pipes primarily for its corrosion resistance, workability, and high level of heat transfer. Copper pipes are used in the transportation industry in car and truck radiators, air conditioning systems and hydraulic lines.

Copper pipe became the most popular choice for plumbing, heating and cooling systems in residential, commercial and industrial buildings.

Copper tubes are currently mainly used in refrigeration system accessories. Their good plasticity, corrosion resistance and thermal conductivity bring coolness to humans.

The medical and construction industries use its good bacteriostasis and corrosion resistance in medical equipment and home decoration drinking water pipes.

External copper is also used in a variety of industries, such as: the motor and cable industries take advantage of its ultra-high electrical conductivity, and the communications industry takes advantage of its good thermal conductivity.

4 Fastest way to cut copper pipe

1.Mechanical cutting

Mechanical cutting is the use of mechanical equipment to cut seamless steel pipes. Common methods include sawing and grinding wheel cutting. These methods are suitable for cutting smaller seamless steel pipes and require a flat and smooth cutting section, so they are not suitable for cutting some large seamless steel pipes.

Cutting copper pipe with saw

Cutting the copper pipe with a hacksaw is one of the most common methods. You need to fix the copper pipe on the workbench with pliers first to avoid the copper pipe shaking during cutting. Then use a hacksaw to slowly saw off the copper pipe along the lateral direction of the pipe. It should be noted that when cutting, you should use even force, not too much force at once.

Pipe cutting

Cutting the copper pipe with a pipe is a more convenient method, and it is suitable for some less thick copper pipes. When using, you can mark the copper pipe first, and then use the pipe to cut the copper pipe along the mark. It should be noted that similar to using a hacksaw, the force should be uniform, otherwise it is easy to damage the copper pipe.

Use pliers to cut off

To cut a copper pipe with pliers, you need to use a strong pair of pliers, clamp the copper pipe hard, and then bend or cut it. It is important to note that when using pliers to cut the copper pipe, choose pliers with moderate strength, and try to ensure uniform force when cutting.

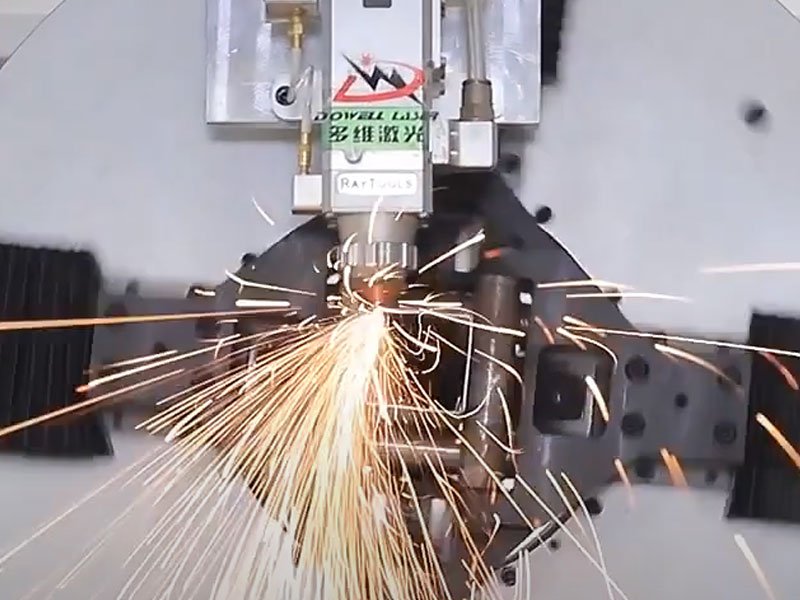

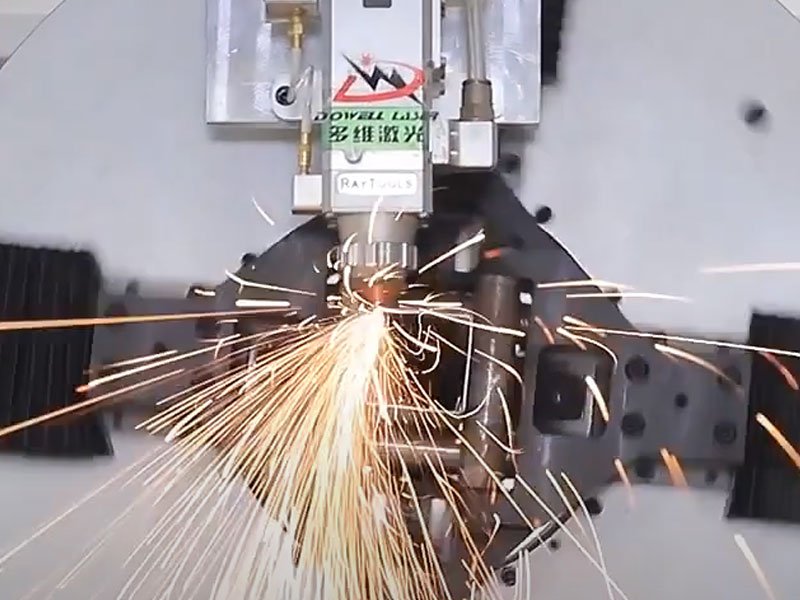

2.Laser tube cutting machine

Laser cutting uses high-energy laser beams to irradiate the surface of seamless steel pipes to quickly melt and vaporize the material to achieve cutting. This method has high precision and fast speed, and is suitable for cutting seamless steel pipes of various materials, especially for thin and thin-walled steel pipes. The cutting equipment is more cost-effective and cost-effective. High, the skill requirements for operators are also high.

3.Flame cutting

Flame cutting is a method that uses high-temperature flames to cut seamless steel pipes. Commonly used methods include gas cutting and plasma cutting. This method is suitable for cutting large seamless steel pipes and has the advantages of fast cutting speed and low cost, but it is easy to cause deformation and oxidation.

4.High pressure water cutting

High-pressure water cutting is an environmentally friendly and efficient cutting method. It uses high-pressure water flow to impact seamless steel pipes to achieve this kind of cutting. The advantage of this method is that the cutting quality is good, no deformation, and no pollution. However, the cost of high-pressure water cutting equipment is relatively high and it is only suitable for some specific materials.

To sum up, different cutting methods can be selected for different seamless steel pipe materials and cutting requirements.

Cutting Copper Pipe Preparation Tools

To cut copper pipes, you need to prepare the following tools:

- Copper pipe cutter

- Metal saw blades

- Gloves

- Goggles

- Ruler

Steps to Cut Copper Pipe

- Choose a suitable pipe cutter: When cutting copper pipes, you need to use a cutter suitable for the diameter of the pipe. Generally speaking, the diameter of the cutter should match the outer diameter of the copper pipe to ensure cutting accuracy and effect.

- Measure and mark: Before cutting, you need to use a ruler to measure the length of the required copper pipe, and then use a pen or other marking tool to mark the edge of the copper pipe.

- Wear gloves and goggles: When cutting copper pipes, you need to wear gloves and goggles to protect your hands and eyes from injury.

- Secure the copper pipe: Clamp the copper pipe to a workbench or clamp to ensure it is stable and does not slip.

- Cut the copper pipe: Use a copper pipe cutter or metal saw blade to cut. You need to use force when cutting, but do not advance it too much, otherwise it will deform the copper pipe.

- Arrange the copper pipes: After cutting, you need to use files, linen or other abrasive tools to remove sharp corners and burrs on the edges of the copper pipes to facilitate installation and connection.

- Check the cutting effect: Finally, the cut copper pipe needs to be inspected to ensure that its length and quality meet the requirements.

Tips for Cutting Copper Pipe

- During the cutting process, be sure to wear gloves and goggles throughout the process to protect yourself from injury.

- Please choose the appropriate cutting tool carefully to ensure its accuracy and effectiveness.

- Use force when cutting, but do not use too much force to avoid deformation of the copper pipe.

- After cutting, it needs to be tidied up in time to remove sharp corners and burrs on the edges of the copper pipes to facilitate installation and connection.

- During the execution process, make sure that the surrounding environment and ground are clean and tidy to avoid accidents.

To master the cutting skills of copper pipes, you need to prepare appropriate tools and pay attention to safety precautions, and you need to operate with caution. I hope the above steps and precautions are helpful to you when cutting copper pipes.

Safety measures for copper pipe cutting

- Labor protection equipment must be worn as required before work.

- Before operation, debris and oil stains around the work site should be removed. The stacking of workpieces must be stable and neat, and must not block the passage.

- Before boarding the ship to remove pipes and valves, first check the purpose and condition of the piping system, and close other valves before and after the pipe or valve to be removed.

How to Cut Copper Pipe Close to Wall

- Measure the size: First, you need to measure the length and angle of the pipe to determine the location and length to be cut.

- Mark cutting lines: Mark the lines to be cut on the pipe. You can use tools such as a ruler or ink pen to mark it out.

- Select cutting tools: Choose appropriate cutting tools based on your needs and your own experience. It is recommended to use spiral pipe cutters, metal saws, electric saws and other tools.

- Preparation before cutting: For larger diameter pipes, you can apply lubrication oil on the pipe to increase the smoothness of cutting. At the same time, wear safety protective equipment such as work gloves and goggles.

- Cutting: Follow the marked lines and use a cutting tool to gradually cut the tube along the marked lines.

How to Cut Copper Pipe in Tight Space

You can use a micro pipe cutter, which can be carried in your pocket and can cut 3-16mm pipes, iron pipes, copper pipes, and aluminum pipes. It is convenient to carry and practical.

How to Cut Galvanized Pipe

- Cut with a pipe wrench: Fix the galvanized pipe on the pipe wrench and cut with a hand saw or electric saw. The operation is simple and suitable for personal DIY operation.

- Cutting with a pipe cutting machine: Use the rotary cutting knife of the pipe cutting machine to place the galvanized pipe on the bracket. The operation is simple and fast.

- Cutting with an angle grinder: This method is suitable for relatively fine cutting. Place the galvanized pipe on the workbench and use the rotation speed of the angle grinder and the cutting disc to complete the cutting.

How to Cut Copper Pipe Without Pipe Cutter

If you don’t have professional pipe cutting tools on hand, you can use pliers and a saw to cut the copper pipe. You’ll need a pair of large pliers and a metal saw. The specific operation method is as follows:

- Clamp the copper pipe with pliers to secure it.

- Use a saw to slowly cut through the copper pipe along the incision. Be careful not to scrape the saw on the pliers to avoid injuring yourself.

- After completing the cutting, use sandpaper to polish the pipe opening to make it smoother.

- Use a pipe cutter

If you need to cut copper pipes frequently, purchasing a professional pipe cutter is your best option. A pipe cutter is a professional pipe cutting tool that comes in different types and sizes. The specific usage is as follows:

- Put the copper pipe into the pipe cutter and select the appropriate cutting opening according to the pipe diameter.

- Hold the handle of the pipe cutter with both hands and press down hard to cut the copper pipe.

- After completing the cutting, use sandpaper to polish the pipe opening to make it smoother.