The topic of metal surface cleaning in the industrial market has never been interrupted, because people need more efficient and less labor-saving methods. Especially in the fields of aerospace and automobile production, it has always been an important topic.

Laser ablation metal cleaning can revolutionize the technology of surface treatment in industry.

What is Laser Ablation Metal Cleaning?

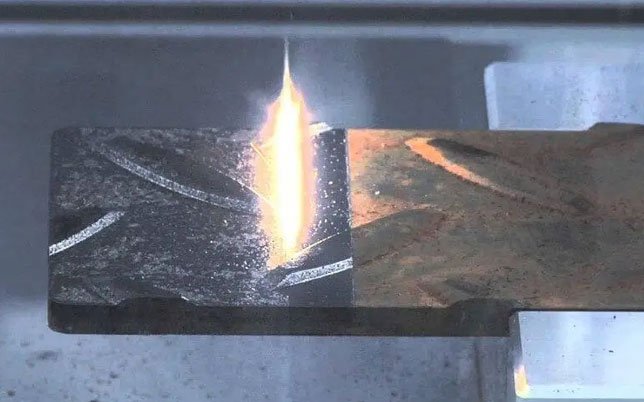

Laser Ablation Metal Cleaning is the use of thermal energy generated by lasers to remove oxides, impurities, welding residues, etc. on the metal surface.

Advantages of laser metal cleaning:

Environmental protection: No need to use chemical reagents, compared with traditional cleaning, it will not cause harm to the environment and human body.

Accuracy: Using the CNC system during operation can accurately remove sundries, which is very important for industries that require high precision.

Small loss: laser ablation metal cleaning non-contact cleaning, will not damage the surface of the substrate.

Efficient: CNC operation, easy to use, convenient and practical

Safety: The safety in the operation process is relatively high, and there are certain dangers in traditional chemical operations.

Laser cleaning solutions application:

Rust removal:

Laser ablation cleaning can easily remove the rust on the metal surface to prepare for the subsequent coating.

Paint removal:

Use handheld laser rust removal to remove paint, not chemical paint strippers.

Metal Surface Debris:

Since welding is required later, it is important to keep the surface clean.

Surface texture:

Sometimes the texture on the metal surface is difficult to deal with, so laser ablation metal cleaning is required.