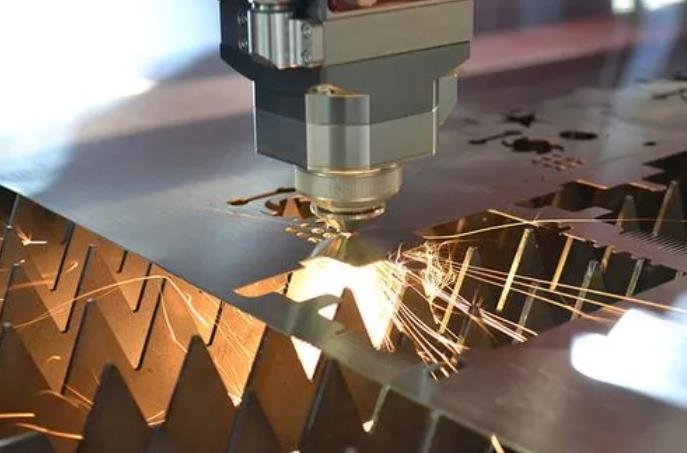

Sheet metal laser cutter is currently widely used in the industrial market, not only because of its efficient cutting ability, but also because of time saving, environmental protection, high precision and other reasons. However, in the face of many How to choose a reasonable laser cutting machine price is a difficult problem for many business owners. This article will help you understand “how much does laser cutting cost”.

Factors that affect laser cutter price:

Why does the laser cutter machine cost of each manufacturer vary, because the cutting format, power size, thickness of the cutting plate, brand of the laser, supplier ability of laser accessories, etc. of the metal laser cutting machine will affect the price cost.

Cutting power and speed: impact on price

Different metal plate laser cutting machines have different powers and different cutting speeds. For the same plate, the higher the power, the higher the cutting speed, and the relative price of fiber laser cutter will be higher.

Laser Types: How They Affect Cost

Fiber laser is the core component of industrial laser cutter, similar to the engine of the car, different fiber laser manufacturers have different brands, different quality, after-sales services, and the higher the price of the laser, for the same reason, as a purchaser of metal laser cutting machine manufacturers, laser cutting machine metal prices will also be relatively expensive.

At present, the cost of fiber lasers on the market varies according to the power, and the price is not too high. Generally, the power of fiber lasers is 1000w-60kw, and the price ranges from US $5,000 to US $600,000. For details, you can consult manufacturers or suppliers.

Size of cutting area: does it matter to pricing?

Another factor that affects the price of laser cutter is the size of the laser cutting machine. Currently, the common ones on the market are 3000*1500mm, 4000*1500mm, 6000*1500mm ,1500*1500mm ,12000*2500mm. Different There are also requirements for the size of the plate. The larger the size, the higher the cost of the metal plate required, and the relative cost of the equipment will be more expensive.

Influence of branding impression on laser cutting system

Different branding impressions, production life and service capabilities are different, and the corresponding prices are also different.

Will they increase costs?

Some customers may want some additional functions for metal laser cutting equipment, such as a large enclosure that is more environmentally friendly, a smoke and dust removal device, and the function of pipe cutting. These all have an impact on the laser cutter machine price.

Find laser cutting machine costs that fit your budget

The price corresponds to your needs

Within the range that you can accept, estimate a reasonable and acceptable laser cutting machine price, and have a psychological expectation.

Evaluate equipment cost and performance

After comparing the performance of the machine, multiple laser cutting equipment manufacturers find out the equipment configuration they want and evaluate the general equipment cost consumption.

Find the price range range

Estimate a price range, perform multiple configurations and comprehensive evaluations of production lead times, service, quality, suppliers, etc.

How much does a laser cutting machine price?

For the entry-level cost of laser cutting machine, the power of the thin plate sheet metal processing industry is 1000w-2000w. Price range: $20000 – $30000.

How much does a cost of laser cutter?

For entry-level cost of co2 laser cutting machine, the power of non-metal cutting machine is 1000w-2000w. Price range: $2000 – $3000

How much does a laser cutter cost for a hobbyist?

Taking into account the economy and cutting power, as an ideal choice for individuals, the general price range is $500 – around $3,500

How much does a small laser cutting machine price?

Compact, efficient and affordable industrial laser cutting equipment. Power range: 1 kW – 3 kW, Price range: USD 30,000 – USD 150,000

How much does an industrial laser metal cutting machine cost?

Industrial laser cutting machines are relatively more expensive and are mainly used to process thick plates of stainless steel and carbon steel. Power range: 2 kW – 60 kW, Price range: USD 40,000 – USD 500,000

Analyzing the Cost-Effectiveness of Laser Cutting Machines

Input-output: The impact of laser cutting machine cost on your profit

Purchasing fiber laser cutting equipment is nothing more than to improve production efficiency and earn more profits. The maintenance cost of the machine, the loss of accessories such as nozzles and lenses, employee costs, etc. need to be considered.

Whether to save costs

Fiber laser cutting equipment preliminary installation and training costs, etc.

If productivity be improved?

After the equipment is purchased, the cutting speed, power consumption, and auxiliary gas cost during use.

Conclusion

The future of laser cutting machines is full of hope and diversification. Whether it is a laser amateur or an industrial market demand, there will be equipment that meets your requirements, and make a reasonable choice from cutting materials, equipment power, manufacturer branding impression, etc.