One of the headaches that many business owners have is rust that develops on metal surfaces over time. Traditional chemical cleaning, physical cleaning and other methods have various shortcomings and problems, such as environmental pollution, safety risks and so on. With the rapid development of science and technology, a new rust removal method has emerged – laser rust removal equipment.

Want to know more about laser rust removal business world , so hurry up and continue the following article.

What is Rust?

Rust, also known as iron oxide, is caused by chemical reactions when iron or alloys are stored in an environment containing moisture and oxygen for a long time.

Effects of rust on materials and substrates:

The appearance of the metal plate after rusting is not very beautiful. If it takes a long time, it will damage the completion of the material structure, and there will be breaks and other sites, which will eventually lead to the loss of the original effect. Especially in the CCB industry, transportation and machinery manufacturing industries, the site of substrate rust is common, and there are potential safety hazards and financial losses.

The importance of rapid and effective rust removal:

Solving rust problems quickly and effectively can extend the life of the material and is safer. If the rusted plate is not treated for a long time, it will cause serious wear and tear, shorten the instructions for use, and cause potential dangers with unpredictable consequences.

Laser rust removal business:

The laser rust removal business is simple to operate, not only efficient, environmentally friendly, but also safe. It is currently a relatively affordable rust removal solution.

History of laser cleaning technology:

Laser cleaning technology first began in the second half of the 20th century. After decades of rapid development, laser cleaning technology has been perfected and can be applied to the rust removal industry more simply and quickly.

How does laser rust removal work?

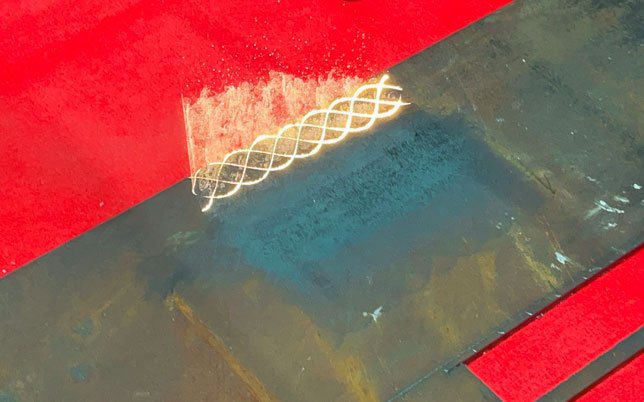

Laser cleaning tools use high-energy heat generated by lasers to quickly remove oxides, rust or paint marks on the surface. The energy generated by the laser is quickly absorbed by the rust and evaporates quickly, leaving a clean surface.

Advantages of laser cleaning business:

- CNC display interface, touch operation;

- No chemical reaction will occur, rust removal is accurate, efficient and environmentally friendly;

- The rust removal process produces little waste, does not touch the base material, and will not cause damage;

- Operators do not need professional certificates to operate.

Benefits of laser cleaning business:

High accuracy:

Precise positioning allows for quick and efficient rust removal, minimizing material waste.

Safety and environmental protection:

Without the need for chemical reagents, laser cleaning can reduce the impact on the environment, reduce the health hazards to operators, and is in line with sustainable development.

Save money:

It requires less labor, is simple to operate, reduces costs and saves labor, saving business owners more money.

Laser rust removal application areas

Manufacturing: Aviation, automobiles, shipbuilding, etc.

Urban infrastructure: Bridges, pipes, public facilities and other urban infrastructure.

Cultural restoration and protection: ancient buildings, artworks, etc.

Cost of laser rust removal cleaning tools expensive?

Laser rust removal cost is related to many factors, such as the area to be cleaned, the type of plate to be cleaned, the power of cleaning, etc.

However, overall, laser rust removal is generally considered a cost-effective method as it saves labor and time costs.

The investment cost of laser rust removal tools in the early stage is relatively high, but in the long run, the maintenance cost is low, the service life of the machine is extended and the work efficiency is improved, which obviously saves money for business owners.

FAQ

Can all rust use a laser rust remover?

Yes, laser rust removal technology can be applied to most surfaces including surface rust and deep rust.

Different types of rust can be treated by adjusting the parameters of the laser equipment.

Will laser rust cleaning machine damage materials?

Will not. Laser rust removal is a non-contact technology that will not cause damage to the surface of the material and is safe and reliable.

How safe is laser rust removal tool

When using laser rust removal, it should be operated according to the safe operating procedures. Operators operate according to the operation manual and wear laser protective helmets and laser goggles during operation to ensure safe operation.