In the welding industry, continuous advancements in technology and equipment have led to increasingly powerful welding machines. Among them, the most top-tier welding machines are not only technologically advanced but also renowned for their high prices. Today, we will explore the most expensive welding machine in the world, understanding its unique features and why it is worth the investment.

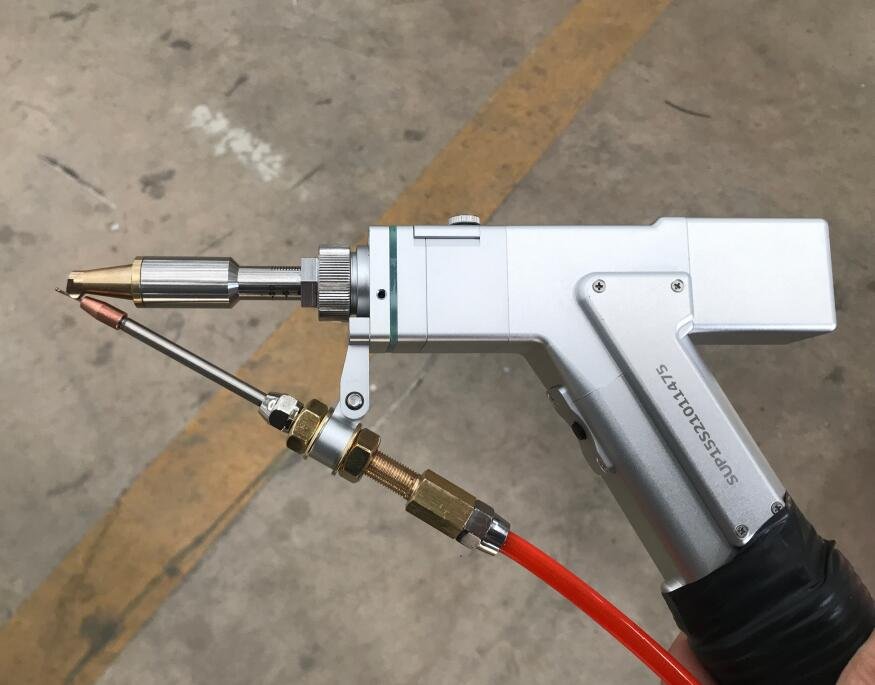

Hand held laser welding machine (spawarka laserowa) is a popular product on the market, and it has also received a lot of recognition and praise from the public. Now the handheld laser welding cost on the market is endless, ranging from 0.5 to 20,000 US dollars. The price is hundreds of times that of argon arc welding. Such a gap is really unacceptable and incomprehensible. Why can laser welding systems be so expensive? Most people said they couldn’t afford it.

Why Is the Handheld Laser Welding Machine Expensive?

Handheld laser welding machine is expensive, because the price of accessories is high, laser welding machine manufacturers cannot adjust the price. Only when the price of accessories is reduced, can the price of the hand laser welder have an opportunity to adjust, but I don’t know whether it will be adjusted upwards or downwards.

The hand-held laser welding machine is most expensive because it is balanced with its own value. Laser fiber welding machine as a new technology equipment, the accessories used are naturally not bad, we mainly talk about its two main components:

Imported well-known brand single mode continuous fiber laser, the system is highly integrated, maintenance-free, and highly reliable.

The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, fine welding and other applications.

Background of the Most Expensive Welding Machines

The high price of welding machines is primarily due to their advanced technology, superior performance, and irreplaceability in specific industries. The main factors include:

- Technological Innovation: These machines often utilize the latest technologies such as laser welding, robotic welding, and automation systems.

- High Precision and Efficiency: They offer exceptional welding precision and speed, suitable for high-end applications like aerospace and automotive manufacturing.

- Durability and Reliability: With a long lifespan and low maintenance costs, they provide great value in the long run.

What is the Configuration of Most Expensive Welding Machine

The most expensive welder currently on the market is the K520 model from Lincoln Electric, which mainly includes power supplies, gas cylinders, tools and welding accessories, etc.

The most expensive welder does not necessarily adopt the best configuration, mainly because it can solve the labor force and improve production efficiency for users, so there is no need to pursue the highest price, focus on quality, service, after-sales, etc.

Features and Functions of Top-Tier Welding Machines

- Laser Welding Machines:

- Representative Brands: Trumpf, IPG Photonics

- Features: High precision, high speed, low heat-affected zone

- Price: Can reach several million dollars

- Friction Welding Machines:

- Representative Brands: KUKA, Thompson Friction Welding

- Features: Suitable for welding high-strength materials, widely used in aerospace and automotive industries

- Price: Can reach several million dollars

- Electron Beam Welding Machines:

- Representative Brands: Sciaky Inc., Pro-Beam

- Features: Can weld in vacuum environments, suitable for high-precision welding

- Price: Typically over a million dollars

Most Expensive Welding Machine in the World

Trumpf TruLaser Cell 8030: This machine represents the pinnacle of laser welding technology, offering extremely high welding precision and speed, widely used in the automotive manufacturing industry. Its price can reach several million dollars.

KUKA KR1000 titan: This is a high-load robotic welding system suitable for heavy manufacturing and aerospace industries. Its price is also in the multi-million dollar range.

Reasons to Invest in the Most Expensive Welding Machine

- Increased Production Efficiency: Efficient welding machines can significantly shorten welding time and increase production efficiency.

- Guaranteed Welding Quality: High-end welding machines provide unparalleled welding quality, reducing rework and scrap rates.

- Adaptability to Complex Applications: Suitable for various complex and high-demand welding tasks, meeting the needs of high-end industries.

- Long-term Cost Savings: Although the initial investment is huge, the high durability and low maintenance costs make the overall ownership cost lower.

How to Save Money When Purchasing a most Expensive Laser Welder

Buy second-hand equipment:

Buying a second-hand laser welding machine can save you money, but there are some points that need to be known. The maintenance cost of the machine is very high.

Consider leasing:

If you are only temporarily welding metal, you can consider leasing a laser welding machine. It can be a short-term project. After the scale expands later, you can consider purchasing a brand new laser welding machine.

Conclusion

While the most expensive welding machines come with a high price tag, the technological advantages and production benefits they bring are irreplaceable. In high-end manufacturing industries, investing in a top-tier welding machine is not only a necessary means to enhance competitiveness but also a wise choice for long-term development.