There are many reasons for errors in fiber laser cut quality troubleshooting in the use of metal fiber laser cutting machines, including errors in the laser cutting process, poor laser cutting results, and so on.

Causes of errors in fiber laser cutting machine processing:

1.Geometric error of workpiece

Due to various reasons, the surface of the processed object is undulating, and heat is generated during the cutting process. In this way, the surface of the thin plate part is easily deformed, and due to the uneven surface, the position of the laser focus and the surface of the processed object will also be different. The ideal situation changes randomly.

2.The cutting thickness of the material exceeds the standard

The cutting material thickness exceeds the standard.

Take 3000W as an example: the plate thickness the laser cutting machine can cut is less than 20 thicknesses. The thinner the plate, the easier it is to cut and the better the quality. If the sheet is thick enough, the laser cutting machine will be easier to cut. Under the condition of ensuring the cutting, there will be errors in the processing accuracy, so the thickness of the sheet must be determined.

3.Errors caused by programming

In the processing of fiber laser cutting machines, the processing trajectory on the complex curved surface is fitted by straight lines, arcs, etc. There are errors between these fitting curves and the actual curves. These errors make the relative position of the proper focus and the surface of the processed object, and An error occurs in the ideal programming position. And some teaching programming systems will also introduce some deviations.

4.The occurrence of focus position error during laser cutting

In the cutting process of the fibre laser cutting machine, many factors cause the relative position between the focus and the surface of the processed object to change, which are also related to the surface smoothness of the processed product, the clamping method of the workpiece, the geometric error of the machine tool, and the long time of the machine tool. Deformation of the load, thermal deformation of the workpiece during processing, etc., will cause the laser focus position to deviate from the ideal given position (programmed position).

Causes and solutions of glitches in laser cutting process

1.The upper and lower positions of the focus deviate.

Solution: Adjust the position of the focus, and adjust it according to the offset position generated by it.

2.The output power of the machine is not enough.

Solution: Whether the laser cutting equipment is working normally. If abnormal, repair and maintain in time.

3.The wire cutting speed is too slow.

Solution: Adjust and increase the wire cutting speed.

4.The purity of the auxiliary gas is not enough.

Solution: improve the purity of the auxiliary gas.

5.The adding point of the laser beam is offset.

Solution: Debug the focus.

6.Instability caused by long operation time.

Solution: Turn off the machine and restart it.

Metal laser cutting machine is a precision CNC cutting machine, laser cutting processing is a delicate work, a data error will cause cutting error, so it is necessary to be precise and rigorous in the work to reduce and avoid errors.

Reasons for deformation during laser cutting machine process

The machine uses pulsed puncture when cutting the small hole, causing the energy to be all concentrated in a small area, causing it to be charred and deform the round hole.

The correct way: adopt the blasting scheme and perforation, and use a low-power laser cutting machine.

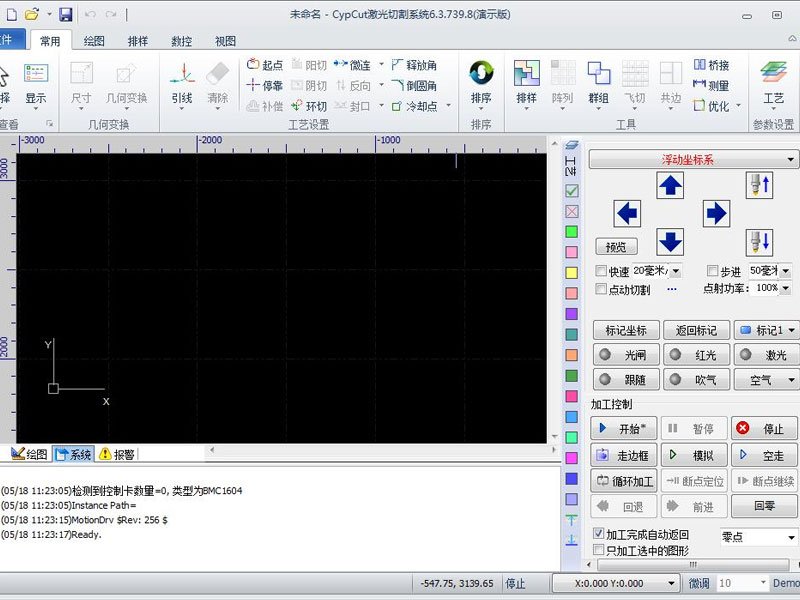

How to program cnc laser cutting machine

- Install CAD software and laser cutting system software on the computer, and CAD draws the graphics that need to be processed.

- Turn on the laser cutting system, and click the online button in the upper right corner to see if it can be connected to the machine.

- Click the setting button-select device parameter setting-controller parameter setting interface to set the motion, processing, and laser power. After setting, click download and confirm.

- Set the layer parameters, click online to cancel the online, click the layer, enter the cutting layer setting interface, check 3 to 4 layers, the specific parameters of the layer are set according to the situation of the machine

- Open the graphics drawn in the CAD software on the interface, and check whether the colors of the graphics layers are consistent.

- Select all graphics (automatic optimization, merge, reverse, merge, sort by distance, sort to the end, online, device control, download current file, confirm, cancel online)

- After completing the above operations, the graphics setting programming on the computer is completed, and then we can process it on the machine.

What software is used for laser cutting machine programming?

There are two main ways to program the laser cutting machine:

CAD software

That is, use the CAD software to input the corresponding graphics, and cut the corresponding pictures through the laser cutting system;

NC programming

Using NC (numerical control) programming to cut the processing material and set the laser cutting machine processing instructions.