In industrial manufacturing, the requirements for the accuracy and efficiency of equipment are very high. The advent of steel pipe laser cutting machines can just meet the needs of business owners.

What is a steel tube laser cutting machine?

Steel pipe laser cutting uses the heat generated by the laser to cut the steel pipe.

Why buy steel pipe laser cutting?

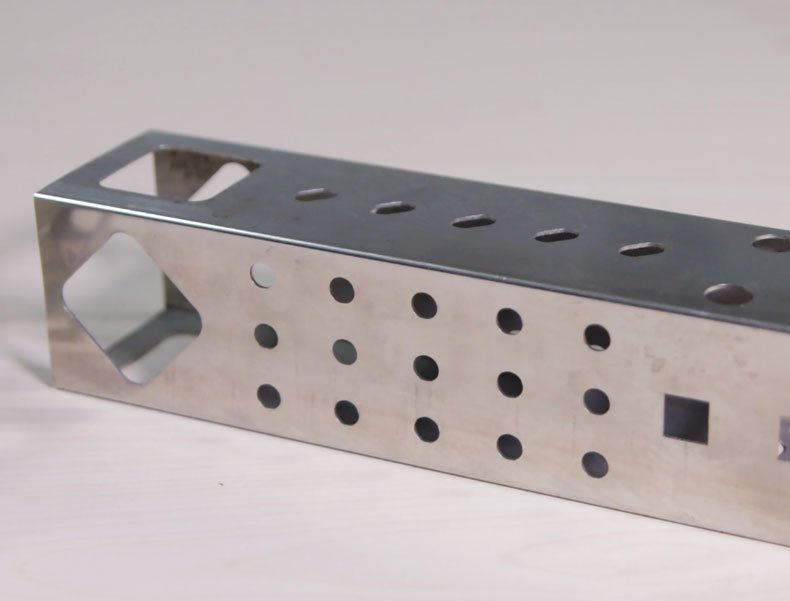

High precision: The machine can cut any graphics on the steel pipe without limitation, with high precision and fast speed.

High efficiency: The production efficiency has been increased thrice, which cannot be achieved manually. Equipped with a loading and unloading device, it can realize bundle cutting.

Versatility: It can cut steel pipes of different thicknesses; round, square, rectangular, channel steel, etc., are all available for cutting.

Material saving: Less material waste can increase the cost savings of becoming a business owner.

High safety: CNC operating system, simple operation, non-contact operation, high safety.

Application fields:

Steel pipe laser cutting machines are widely used in the industrial market, especially in manufacturing.

- Automotive field: in the manufacture of automotive engine parts, exhaust systems, and other precision components;

- Aerospace field: components that can withstand high-pressure price adjustments;

- Steel structure field: rail transit, steel structure used in bridge construction;

- Furniture manufacturing: metal pipe furniture manufacturing, especially cutting complex graphics;

Conclusion

Laser cutting steel pipe machine breaks the cognitive boundaries of traditional industries and is not just a device for cutting pipes. C steel tube laser cutting machine factories can not only optimize the flow of production but also maintain competitiveness.