The rapid development of laser cutting technology has brought benefits to the manufacturing industry. Because of its high precision, it is favored by business owners. For beginner laser cutter to laser cutting machines: How Thick Can a Laser Cutter Cut Steel? is a topic that everyone pays more attention to. This article will give you the answer in detail, focusing on Dowell’s laser cutting equipment.

20kw laser cutter steel

What is laser cutting

For laser steel cutting machine beginners, it is very important to understand what laser cutting is. Laser cutting is a kind of high energy generated by fiber laser to melt, burn or vaporize the material on the metal surface, so as to achieve the effect of cutting. Sheet metal laser cutting machine is widely used in fitness equipment, agricultural machinery production, advertising signs, precision electronics, steel structure fields, shipbuilding, aerospace fields, etc.

What factors affect laser cutting steel thickness

The factors of steel laser cutter include: fiber laser type, laser power size, laser cutting head brand, auxiliary gas type and focus size.

Fiber Laser Type:

- CO2 lasers: mainly suitable for cutting, engraving and drilling

- Fiber Lasers: Higher Cutting Accuracy, Faster Speeds

Fiber laser power:

The power of the laser determines the thickness of the laser cutting machine for steel. The higher the power, the thicker the steel plate cut and the faster the speed.

Generally, for cutting thin plates (0.2~4mm thick), it is enough to use 500W or 1000W cnc laser cutter steel.

Auxiliary gas

The type of assist gas used also affects the laser cutting capaticy. Typically oxygen, nitrogen and compressed air are used. Helps to increase cutting speed and can cut thicker steel plates.

Cut focus size

The size of the focus of laser cutting is also very important. The smaller the focus, the more concentrated the laser is, which can achieve the cutting effect of thick plates.

Fiber laser cutting thickness chart

The thickness of the plate is different, and the power of the laser used is different. Knowing the maximum thickness for laser cutting of each power can avoid the waste of manpower. I hope the following laser cutting thickness and speed chart will be helpful to you.

| Laser Power (W) | Carbon Steel (mm) | Stainless Steel (mm) | Aluminum Alloy (mm) | Brass (mm) |

|---|---|---|---|---|

| 1000w | 0.8-10 | 0.8-5 | 0.8-3 | 1-3 |

| 1500w | 1-16 | 1-6 | 1-4 | 1-3 |

| 2000w | 1-20 | 1-8 | 1-6 | 1-5 |

| 3000-3300w | 1-22 | 1-10 | 1-8 | 1-6 |

| 4000w | 1-25 | 1-15 | 1-10 | 1-8 |

| 6000w | 1-30 | 1-20 | 1-20 | 1-12 |

| 8000w | 1-40 | 1-30 | 1-30 | 1-16 |

| 10000w | 1-45 | 1-40 | 1-40 | 1-20 |

| 12000w | 1-50 | 1-45 | 1-45 | 1-20 |

| 15000w | 1-60 | 1-50 | 1-40 | 1-20 |

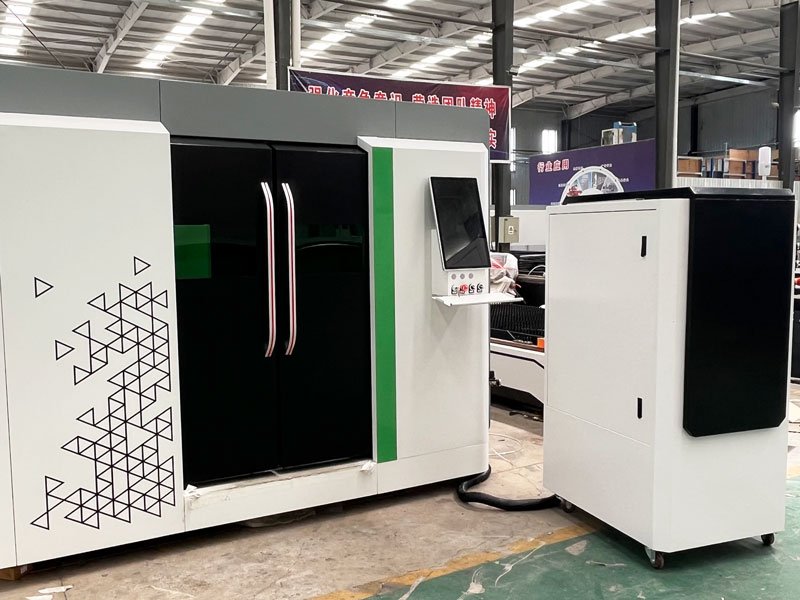

Dowell steel laser cutting machines manufacturers

DOWELL Laser has focused on the production and development of laser equipment for 13 years, including the cutting of metal materials such as stainless steel, carbon steel, and brass. The products are exported to 80+ countries and regions at home and abroad, and the highest can achieve 30kw laser cutting equipment, cutting 40mm carbon steel.

Conclusion

Whether you are in bridge construction, steel structure production, track construction and other industries, if you want to achieve efficient precision cutting, DOWELL cnc laser cutter steel will be the best choice. I hope our equipment can help your business .

FAQ about steel laser cutting machine

What size laser to cut metal

At present, the size of laser cutting bed on the market is average.

- Compact laser cutting machine: 1300*900mm, 1300*1300mm,1300*2500mm,1500*1500mm

- Small format laser cutting machine: 3000*1500mm, 4000*1500mm, 6000*1500mm, 4000*2000mm

- Large format laser cutting machine: 8000*2500mm, 12000*2500mm, 14000*3000mm

Where to buy laser cutting materials

To purchase laser-cut materials, you can go to the plate market near your home, or I can purchase on Amazon, Alibaba, AliExpress and other e-commerce platforms, and there are metal plate agents, after all, the quality is guaranteed.

Laser cutting steel cost per inch

Laser cutting steel cost per inch is due to many factors, such as the thickness of the metal plate, size, auxiliary gas and other factors. Under normal circumstances, the cost per inch of laser cutting steel is between US$0.75-US$2. Of course, this depends on the price of each place. Different policies and different electricity charges will have some differences.

Can laser cutter cut metal

Laser cutting steel plate is mainly used to cut metal materials, steel, stainless steel, carbon steel, aluminum plate, brass, etc., thin metal thick metal can be.