Ventilation conditions are very important for laser cutting machines. Good ventilation can extend the life of laser cutting equipment and achieve better cutting results. This article will give you a detailed description of laser cutter ventilation requirements.

Why laser cutter ventilation

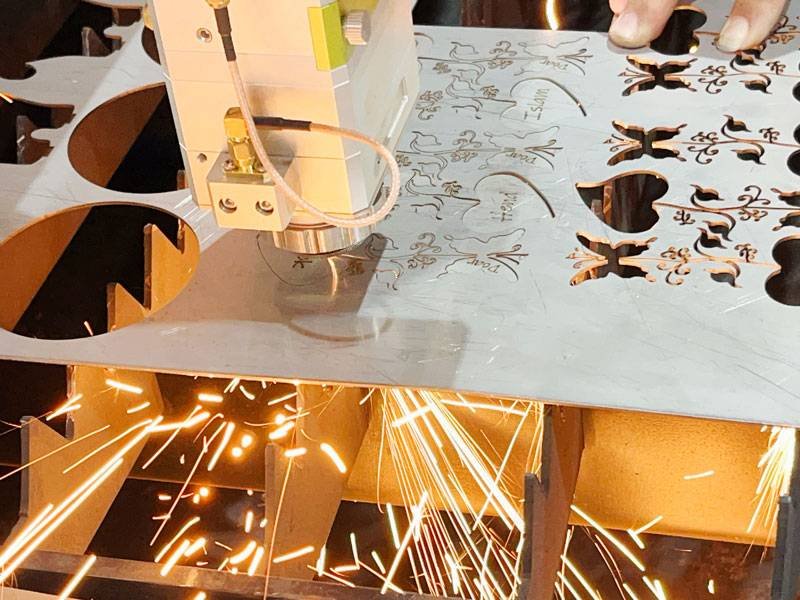

When the metal laser cutting machine cuts the metal sheet, the high-energy heat melts the metal sheet for the purpose of cutting. Therefore, a large amount of exhaust gas is produced during the cutting process, which is harmful to the health of the operator. Therefore, the laser cutter ventilation system has certain requirements. required.

What are the laser cutter ventilation requirements?

Exhaust treatment only targets part of the cutting surface, so that the local working area environment is not polluted.

Good air environment. The local exhaust fan unit consists of 4 parts: air collecting hood, air duct, purification system and fan.

Local exhaust is divided into fixed local exhaust system and mobile local exhaust system according to the gas collection method. Fixed local exhaust systems are mainly used in large-scale CNC cutting production workshops, where the operating positions and workers’ operating methods are fixed.

The position of the air collecting hood is fixed once according to the actual situation. The working state of the mobile local exhaust system is relatively flexible, and different working postures can be adopted according to different working conditions to ensure processing efficiency and operator convenience.

The purification system for CNC cutting flue gas and harmful gases usually uses bag type or electrostatic precipitator combined with adsorbent purification method, which has high processing efficiency and stable working condition.

Comprehensive ventilation is also called dilution ventilation. Clean air dilutes the concentration of harmful substances in indoor air so that the concentration of harmful substances in indoor air does not exceed the maximum allowable concentration specified by health standards. At the same time, polluted air is continuously discharged to the outside or collected and purified. Comprehensive ventilation includes natural ventilation and mechanical ventilation.

Outdoor CNC cutting operations or CNC cutting in open spaces use natural ventilation, while indoor operations use mechanical ventilation.

Through the axial flow fan installed on the wall or ceiling, the welding smoke in the workshop is discharged to the outside, or it can be recycled in the workshop after being purified by the purifier, so as to reduce the concentration of smoke in the workshop.