The laser welding process is well received in the field of laser welding because of its high energy density heat source, high brightness of laser energy, good directionality, and good monochromaticity, which can melt metal. Next, let us learn about the laser beam welding process together!

What is fiber laser welding process

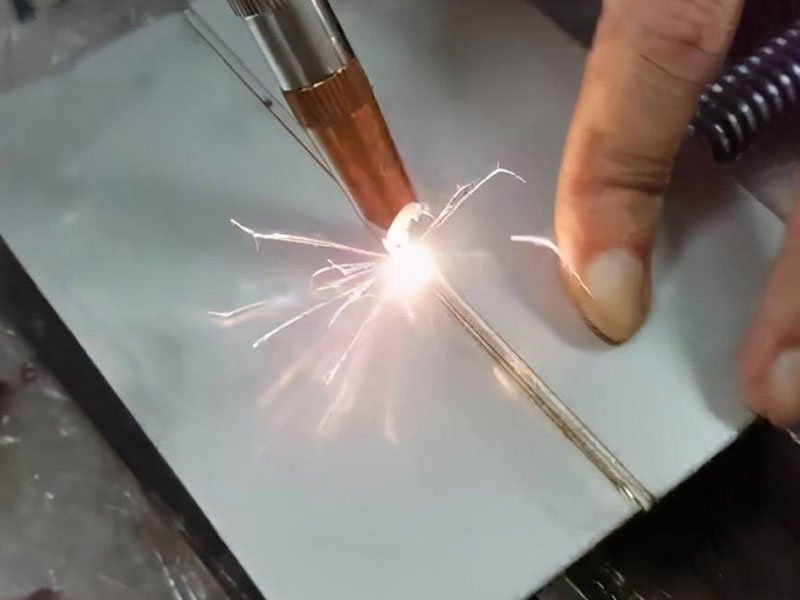

Laser welding techniques use high-energy laser pulses to locally heat materials in a small area. The energy of laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

Laser welding is mainly aimed at welding thin-walled materials and precision parts. It has a high aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful welds, and no post-welding processing or only simple processing. , the welding seam is of high quality, no pores, can be precisely controlled, the focused light spot is small, the positioning accuracy is high, and it is easy to realize automation.

Laser welding machine welding methods

Laser welding machines can realize spot welding, butt welding, stack welding, tailor welding, laser hybrid welding, seal welding, etc. Among them, laser tailor welding and laser hybrid welding technology and equipment are mainly used for high-strength welding of trains and automobile plates. There is widespread demand in other areas as well.

Steel plate laser tailor welding and laser hybrid welding are laser tailor welding technologies that integrate straight line and zigzag line tailor welding functions. They are suitable for straight line, curve, and fold line tailor welding of plates, and are suitable for plates of different materials, thicknesses, coatings, and shapes.

Laser welding process video

how does laser welding work

Laser welding machine settings

Laser welding machine process flow

Achieve all-position welding

First, make the welding object and the weld seam horizontally butt together, so that all-position welding can be achieved. In actual on-site welding, we use upward welding from the bottom and fill the wire at the same time. Welding to the outside changes to vertical welding and flat welding to avoid concave internal welds. At the same time, all-position welding is achieved.

Horizontal butt joint between welding material and welding seam

During the welding process, avoid contact between the welding wire and the tungsten electrode to avoid affecting the quality of arc welding. Before starting the arc, feed pure argon gas to replace the air in the original tube, and then proceed with arc welding.

Feed wire

After the arc is ignited, the metal wire is first fed in, either mechanically or manually. The high temperature of the molten pool is used to melt the wire before welding can be carried out.

Soldering process

During the welding process, care should be taken to avoid the formation of pores, and care should also be taken not to disturb the argon gas flow, otherwise it will easily cause the molten pool to be oxidized, and the argon gas will lose its protective effect and lead to oxidation of the weld. The tungsten electrode should be perpendicular to the axis.

The plate rolling machine can control the size of the welding pool to avoid the oxidation problem of the molten pool caused by the nozzle during the welding process. Just ensure that the welding wire is continuously fed into the molten pool. The speed should not be too fast or too slow. Just weld it through.

Stop arc

Make sure the weld has been penetrated, then pull out the welding wire, and then put out the fire and stop welding after the welding wire is pulled out. The extraction speed should be slow to prevent the molten pool from being oxidized, and then the argon protective gas flow should be stopped to achieve quality control of the entire on-site welding process.

Compared with traditional arc welding process:

- Selective energy application in small areas: reduced thermal stress and heat affected zone, extremely low distortion.

- Narrow seams and smooth surfaces: reduce or even eliminate reprocessing.

- High strength combined with low welding volume: the welded workpiece can undergo bending or hydroforming.

- Easy to integrate: can be combined with other production operations such as alignment or bending.

- Only one side of the seam needs to be closed.

- High process speeds reduce processing times.

- Especially suitable for automation technology.

- Good process control: Machine tool control and sensor systems detect process parameters and ensure quality.

- The laser beam can create welds without touching the surface of the workpiece or exerting force on the workpiece.

Influencing factors of laser welding process quality

The main factors affecting the quality of laser welding are divided into three aspects: welding equipment, workpiece condition and process parameters.

Welding equipment

The most important quality requirements for lasers are beam pattern and output power, as well as their stability.

The lower the beam pattern order, the better the beam focusing performance, the smaller the spot, the higher the power density under the same laser power, and the larger the weld depth and width.

Generally, the basic mode (TEM00) or low-order mode is required, otherwise it will be difficult to meet the requirements of high-quality laser welding.

The biggest factor affecting the welding quality of the optical system is the focusing lens. The focal length used is generally between 127mm (5in) and 200mm (7.9in). A small focal length is beneficial to reducing the focus beam waist spot diameter, but if it is too small, it will easily cause damage during the welding process. Damaged by contamination and splash.

The shorter the wavelength, the higher the absorption.

Generally, materials with good electrical conductivity have higher reflectivity. The reflectivity of YAG laser is 96% for silver, 92% for aluminum, 90% for copper and 60% for iron. The higher the temperature, the higher the absorbance, showing a linear relationship. Generally, surface coating with phosphate, carbon black, graphite, etc. can improve the absorption rate.

Workpiece condition

Laser welding requires high edge precision of the workpiece being processed and assembled, strict alignment of welding points and weld seams, and the original assembly accuracy and point alignment of the workpiece during the welding process are not distorted by the welding heat.

This is because the laser spot is small, the weld is narrow, and filler metal is generally not added.

If the assembly gap is too large, the beam can pass through the gap without melting the base material, or cause obvious light punching and denting. If the point-to-seam deviation is slightly larger, it may lead to incomplete fusion or incomplete welding.

Generally, the assembly gap and point seam deviation of board butt joints should not be greater than 0.1mm, and the misalignment should not be greater than 0.2mm.

Welding parameters

(1) Impact on laser welding method and weld formation stability. The most important welding parameter is the power density of laser spot. Its impact on welding method and weld formation stability is as follows.

The laser spot power density from small to large is stable heat conduction welding, mode unstable welding and stable deep penetration welding.

The laser spot power density, under a certain beam mode and focusing mirror focal length, is mainly determined by the laser power and beam focus position.

Laser power density is directly proportional to laser power.

(2) In the range of deep penetration welding, the influence of welding parameters on penetration depth:

Within the stable deep penetration welding range, the higher the laser power, the greater the penetration depth, about 0.7 times.

Moreover, the higher the welding speed, the shallower the penetration depth.

Under certain conditions of laser power and welding speed, the focus is in the best position when the penetration is maximum.

If it deviates from this position, the penetration depth decreases and even becomes unstable welding or stable heat conduction welding mode.

(3) The role of protective gas

Protect the workpiece from oxidation during welding. Protect the focusing lens from metal vapor contamination and liquid droplet sputtering. Disperse the plasma generated by high-power laser welding. Cool the workpiece and reduce the heat affected zone.

The shielding gas is usually argon or helium, or nitrogen if the apparent mass is not high.

(4) Monitorability analysis of each parameter.

Among the four welding parameters, welding speed and shielding gas flow are parameters that are easy to monitor and remain stable, while laser power and focus position are parameters that may fluctuate during the welding process and are difficult to monitor.

The focus position of the beam is one of the most difficult factors to monitor and control among the welding parameters that affect weld quality.

Currently in production, manual adjustments and repeated process tests are required to determine the appropriate focus position to obtain the required melt depth.

Influence laser welding process parameters

The welding process parameters that affect welding quality mainly include laser output power, welding speed, laser waveform, pulse width, defocus amount, and shielding gas.

- Power density

Power density is one of the most critical parameters in laser processing. Using a higher power density, the surface layer can be heated to the boiling point within a microsecond time range, resulting in a large amount of vaporization. Therefore, high power density is beneficial for material processing, such as drilling, cutting, and engraving.

For lower power densities, it takes several milliseconds for the surface temperature to reach the boiling point. Before the surface layer vaporizes, the bottom layer reaches the melting point, making it easy to form a good molten weld. Therefore, in conductive laser welding, the power density ranges from 104 to 106 W/cm2.

- Laser pulse waveform

Laser pulse waveform is an important issue in laser welding, especially for thin sheet welding. When a high-intensity laser beam hits the surface of a material, 60 to 98% of the laser energy will be reflected and lost on the metal surface, and the reflectivity changes with the surface temperature. During the action of a laser pulse, the reflectivity of metal changes greatly.

- Laser pulse width

Pulse width is one of the important parameters of pulse laser welding. It is not only an important parameter different from material removal and material melting, but also a key parameter that determines the cost and volume of processing equipment.

- The influence of defocus on welding quality

Laser welding usually requires a certain amount of defocus because the power density at the center of the spot at the laser focus is too high and can easily evaporate into holes. On each plane away from the laser focus, the power density distribution is relatively uniform.

Laser welding applications

Laser welding technology is widely used in foreign car manufacturing. At the same time, laser welding machines are widely used in the electronic industry, powder metallurgy, biomedicine and other industries, such as laser welding of BT20 titanium alloy, HEl30 alloy, Li-ion batteries, etc. Germany has developed a new laser welding technology for flat glass.

What is specific process energy in laser welding

The specific process energy in laser welding isn’t a single fixed value , but rather depends on several factors. Here’s why:

Laser Power and Beam Size: Higher laser power delivers more energy, but a larger beam diameter spreads that energy out, reducing the energy density.

Welding Speed: Faster welding speeds mean less time for the energy to heat the material, requiring higher power to achieve the same weld depth.

Material Properties: Different materials have varying absorption rates for laser light, affecting how much energy goes into melting the metal.

Joint Geometry: Thicker materials or deeper welds require more energy compared to thin sheets or shallow welds.

Laser welding equipment and process validation

Laser welding is a precise and versatile joining technique that utilizes a concentrated beam of light to melt and fuse materials. It offers numerous advantages over traditional welding methods, including:

- Stronger, more precise welds: Laser welds are often deeper and narrower than other welds, leading to higher strength and a more aesthetically pleasing finish.

- Minimal heat distortion: The concentrated nature of the laser beam minimizes heat transfer to surrounding areas, reducing warpage and distortion.

- Suitable for thin materials: Laser welding is ideal for joining thin sheets of metal without the risk of burn-through.

- Wide range of materials: Laser welding can weld a variety of metals, including steel, aluminum, titanium, and nickel alloys.

Laser welding solutions

The cost of welding equipment is very high, and the energy utilization rate of lasers is low. Taking lasers as an example, the total efficiency is only 20%. Moreover, high-power lasers consume a huge amount of expensive He gas when running, and the production cost also increases greatly.

However, the penetration depth of laser welding does not increase in direct proportion to the laser power. Taking low carbon steel welding aids as an example, the welding penetration depth is approximately proportional to the power of 0.6. Under 20kw laser power dyeing, the maximum tower depth is 15-20mm, and the maximum penetration depth is only 45mm when the power reaches 90KW.

The main reason is:

(1) When the penetration depth increases further, the molten metal on the side wall of the welding joint will bridge and hinder the passage of the laser;

(2) High-power laser welding produces a large number of contour plasmas, and it is becoming more and more difficult to remove the plasma, and the shielding of the laser is becoming more and more serious.

FAQ

Is laser welding a fusion welding process ?

Laser welding technology is a fusion welding technology that uses laser beam as energy to impact on the joints of welded parts to achieve the purpose of welding.

In a laser beam welding process what quantity of heat

The heat-affected zone of laser welding is very small, usually only a few millimeters, and does not generate excessive heat on the workpiece.

What is the smallest hole that can be drilled with a laser welding process?

Laser welding aperture sizes range from 0.1 to 10 millimeters.