When many customers plan to buy laser cutting equipment, they do not know the difference between sheets and plates. This article will tell you the difference between sheets and plates.

What is Plate Steel

Plate generally refers to metal materials with a thickness of 3 mm or more. It has relatively good formability and weldability. It is often used to make heavy equipment such as vehicles, aircraft, and buildings and components covering large areas.

What Metal is Sheet Metal

Sheet refers to a metal material with a thickness of less than or equal to 3mm. It has high ductility, strength and hardness and is often used to make precision parts and decorations such as parts, packaging materials, and electronic components.

Manufacturing Process: Sheet Steel Vs Plate Steel

Sheets are usually produced by rolling metal between large rollers to achieve the desired thickness, while plates may be produced by rolling or by directly casting molten metal into molds and then cooling and solidifying it.

What is the Difference Between Sheet VS Plate

Sheet metal vs plate steel is a kind of metal material, which is widely used in industrial production and manufacturing.

Characteristics of Sheet VS Plate Steel

The plate has a larger area and thickness, higher hardness and strength, and greater weight and strength.

Plates have good formability and can be made into components of various shapes and sizes by simple processing methods such as stamping and bending.

With good weldability and machinability, it is suitable for welding, cutting and other processing methods, making it more practical.

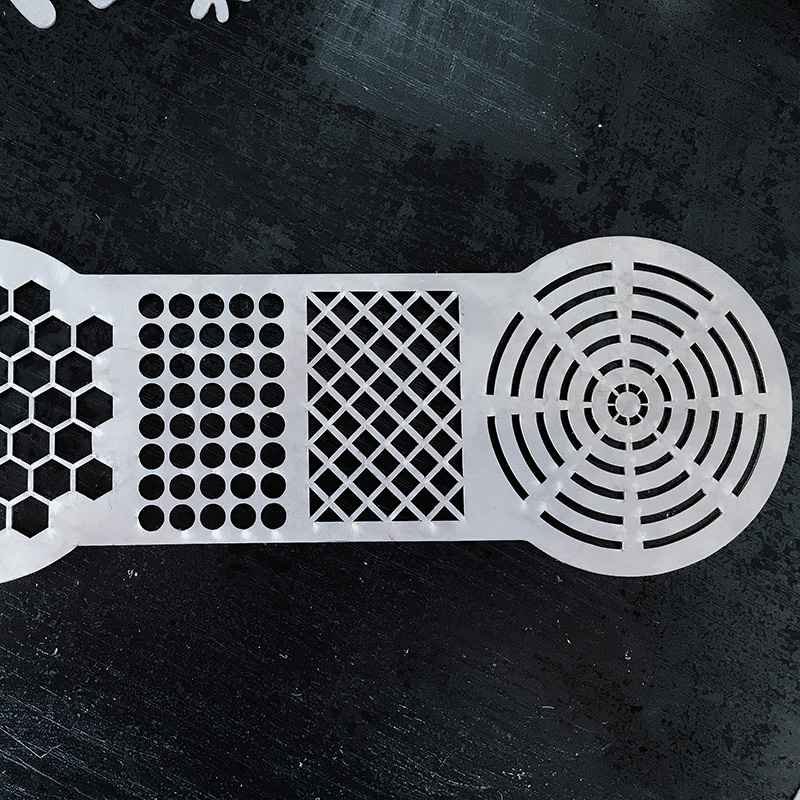

Due to its thin thickness, the sheet has good ductility and toughness, and can be easily folded into various shapes. Processing requires relatively high precision and skills, and is suitable for manufacturing high-precision and precision parts and decorations.

Steel Plate Vs Sheet Application Field

As a relatively heavy material, sheet metal is widely used in construction, transportation, machinery manufacturing, chemical industry, metallurgy and many other fields. Mainly used in the manufacture of ships, automobiles, aircraft, bridges, buildings, water conservancy facilities and other heavy components and equipment.

Sheets are used in more sophisticated fields, including electronic components, chemical containers, packaging materials, wearable devices, etc. Widely used in architectural decoration, household items and other fields, high precision and detail are its outstanding features.

Cost

The steel plate cost is more expensive than the sheet material, because the steel plate is relatively thicker and the production cost is higher, so the steel plate pricing is also higher.

Sheet steel vs plate steel each has its own characteristics and application fields in the application of metal materials. For different projects and needs, choosing the right materials is the key to ensuring product quality and production efficiency.

Difference Between Sheet and Plate in mm

The main difference between a sheet and a plate lies in their thickness. Sheets are typically thinner than plates. Sheets are usually less than 6mm thick, while plates are thicker, generally ranging from 6mm to 150mm or more. Plates are often used in structural applications where strength and durability are key, while sheets are commonly used in applications where weight and flexibility are more important factors.

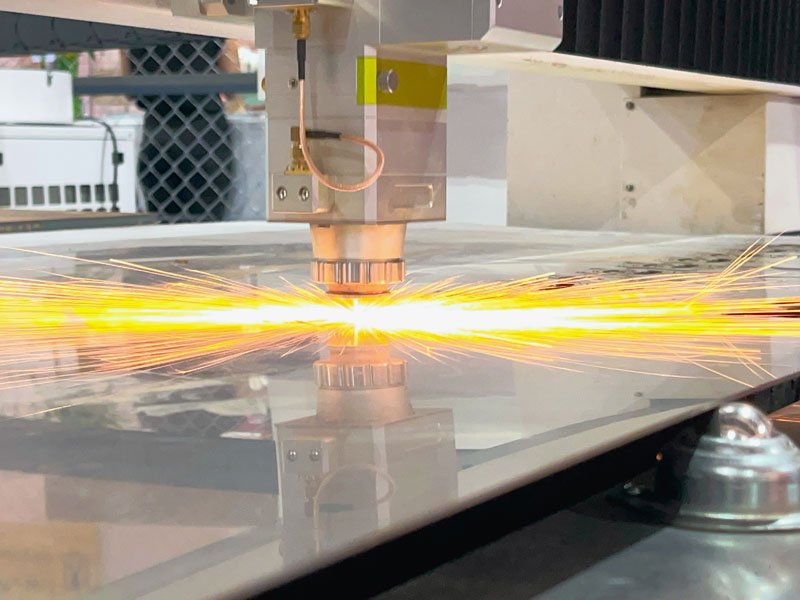

Now you know the difference between sheet metal vs plate. If you want to buy a suitable sheet metal cutting machine, we recommend DOWELL laser cutting equipment. We have 1kw-60kw laser cutting equipment for you to choose from. The company can improve customization needs, mail samples, and provide proofing for free. Please feel free to contact DOWELL laser!