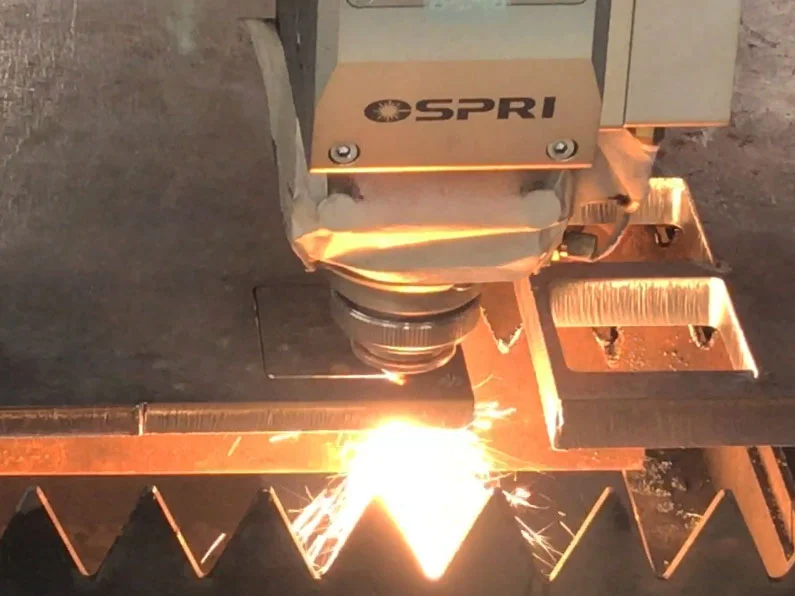

During laser metal cutting, auxiliary gas is commonly used. It helps the laser cutter function more effectively and achieve clean, smooth cuts.This article will provide an in-depth introduction to gas used in laser cutting. I hope it will be helpful for laser cutting machine beginners.

Which gas is used in laser cutting machine

Laser Cutting Gas is very common in metal cutting.The cutting process used and the material to be cut determine the type of auxiliary gas (inert or active gas) most suitable for use. An inert gas cutting (ie, melting cutting or inert gas melt shearing) uses a chemically inert auxiliary gas.

- Inert gas: Gas that does not react chemically with the material being cut.

- Reactive gases: Gases that can react chemically with the material being cut, often speeding up the cutting process.

Difference laser cutting assist gas

| Property | Inert Gases | Reactive Gases |

|---|---|---|

| Chemical Reactivity | Do not react with the material being cut. | React with the material being cut. |

| Primary Function | Assist cutting process and protect cut edge. | Accelerate cutting process. |

| Common Gases | Nitrogen (N₂), Argon (Ar), Helium (He) | Oxygen (O₂) |

| Suitable Materials | Wide range of metals, including stainless steel, mild steel, and aluminum. | Highly reflective metals like brass, bronze, and copper. |

| Cut Quality | Clean cuts with minimal oxidation. | Can lead to rougher cut edge with more oxidation. |

| Cutting Speed | Slower cutting speeds. | Faster cutting speeds, especially for thicker materials. |

| Cost | Nitrogen is relatively inexpensive. Argon and helium are more expensive. | Oxygen is relatively inexpensive. |

Types of laser cutting assist gas

Inert Gases

| Gas | Properties | Suitable Materials |

|---|---|---|

| Nitrogen (N₂) | – Most widely used inert gas. – Produces clean cuts with minimal oxidation. – Suitable for a variety of metals. | Stainless steel, mild steel, galvanized steel, UHSS automotive steels |

| Argon (Ar) | – Less common than nitrogen. – Suitable for cutting reactive metals like titanium and magnesium. | Titanium, magnesium |

| Helium (He) | – Rarely used in pure form due to high cost. – Can be used in mixtures with other gases for specific applications. | Specific applications where other gases are not suitable |

Reactive Gases

| Gas | Properties | Suitable Materials |

|---|---|---|

| Oxygen (O₂) | Useful for cutting highly reflective metals like brass, bronze, and copper. Accelerates cutting speed. | Brass, bronze, copper, thicker steel materials |

Effect of gas pressure on laser cutting

Gas pressure plays a crucial role in the laser cutting process, significantly affecting cut quality, speed, and efficiency. Here’s a breakdown of the effects of gas pressure:

Impact on Cutting Quality:

- Too Low Pressure:

- Incomplete cutting: The gas jet might not have enough force to effectively remove molten material from the kerf (cut path), leading to incomplete cutting or dross formation (solidified metal sticking to the cut edge).

- Wider kerf: The molten material can’t be expelled efficiently, resulting in a wider kerf and potentially affecting dimensional accuracy.

- Increased surface roughness: Incomplete removal of molten material can leave a rougher cut surface.

- Optimal Pressure:

- Clean cuts: The correct gas pressure ensures efficient removal of molten material, leading to clean and precise cuts with minimal dross.

- Narrow kerf: The focused gas jet minimizes the kerf width, improving dimensional accuracy and material utilization.

- Smooth surface finish: Proper expulsion of molten material contributes to a smoother cut surface.

- Too High Pressure:

- Excessive burning: High pressure can cause the assist gas (like oxygen) to react excessively with the material, leading to excessive burning and a rougher cut edge.

- Warping: In some materials, excessively high pressure can cause warping or deformation at the cutting edge due to intense localized heat.

- Material waste: Higher pressure can lead to more material being vaporized or blown away, potentially increasing material waste.

Cutting Speed:

- Higher pressure with some reactive gases (like oxygen) can sometimes increase cutting speed, especially for thicker materials. The reactive gas can accelerate the cutting process by burning away the material at the cutting edge.

Other Considerations:

- Gas type: The optimal pressure varies depending on the gas used. Inert gases like nitrogen typically require lower pressure compared to reactive gases like oxygen.

- Material type: Different materials have varying melting points and reactivity. The optimal pressure will be adjusted based on the material being cut.

- Laser power: The laser power setting also influences the required gas pressure. Higher laser power might require slightly adjusted gas pressure settings for optimal cutting.

Factors Affecting Laser Cutting Gas

- Material type: Different metals respond better to inert or reactive gases for clean and efficient cutting.

- Cut Quality: For clean, unoxidized edges, nitrogen is preferred. If cutting speed or thicker cuts are a priority, oxygen may be a better choice.

- Laser power: Low-power lasers may benefit from using oxygen for thicker cuts.

How to choose gas used in laser cutting

1.The specific auxiliary gas used depends on the reactivity of the material.

Laser Cutting and Assist Gas Selection:

- Thermoplastics: These non-reactive materials can be cut with compressed air as an assist gas since nitrogen and oxygen won’t cause a chemical reaction with the molten plastic.

- Titanium: Due to its reactive nature with nitrogen and oxygen, argon or other inert gases are necessary as the assist gas when laser cutting titanium.

- Stainless Steel: Inert gas cutting with nitrogen is the preferred method for stainless steel as molten steel reacts with oxygen. Nitrogen helps remove molten material and minimize oxidation.

- Reactive vs. Inert Gas Cutting:

- Reactive Gas Cutting (e.g., with oxygen): This method utilizes an exothermic reaction between the gas and the material to generate additional heat, allowing for faster cutting speeds and potentially lower laser power compared to inert gas cutting.

- Inert Gas Cutting (e.g., with nitrogen): Here, only the laser beam’s power melts and vaporizes the material. The assist gas (like nitrogen) primarily removes molten material and protects the cut edge from excessive oxidation.

2.The cutting pressure of the auxiliary gas depends on the cutting process, material characteristics, and thickness.

For example, in an inert gas cutting process, polymers usually require a gas injection pressure of 2-6 bar, while stainless steel requires a gas injection pressure of 8-14 bar. For most cutting processes, gas pressure increases with material thickness. However, oxidative cutting works the other way around – thicker materials need lower pressure.