In the rapidly growing field of industrial manufacturing, heavy duty, large scale tube laser cutting machines have become key tools. These machines are more than just a laser device. They represent a major leap forward in laser technology, providing unprecedented precision and efficiency in processing large metal tube materials.

Applications of big pipe laser cutting machines span industries from automotive to heavy machinery, highlighting their versatility and indispensability. Their ability to cut thick, large-diameter tubing with unparalleled precision makes them a critical asset for any industrial manufacturing or procurement operation.

This blog post delves into the intricacies of big pipe laser cutting machines, clarifying their operation, benefits, and factors to consider With a complete understanding of their capabilities and market trends, business owners can make informed decisions to ensure their investments not only meet current needs but also pave the way for future growth and efficiency.

What is a big pipe laser cutting machine?

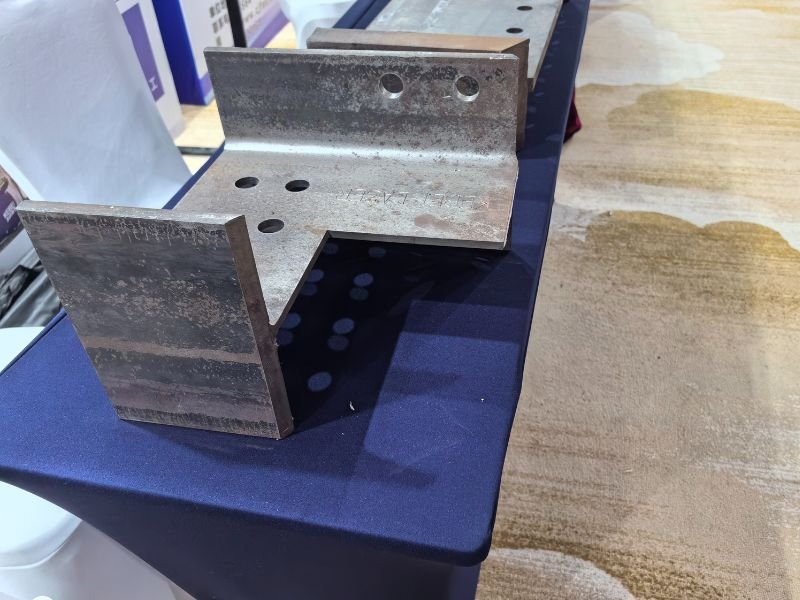

Big pipe laser cutters (Large pipe laser cutting machines) are precision equipment specifically designed for precision cutting of large diameter tubes. These machines utilize high-power laser beams as a cutting source, providing unparalleled precision when cutting a wide variety of materials, including metals such as steel, aluminum, and copper. The laser’s high focus allows it to make clean, smooth cuts with minimal material waste, a key factor in large scale manufacturing.

Type of big pipe laser cutting machine

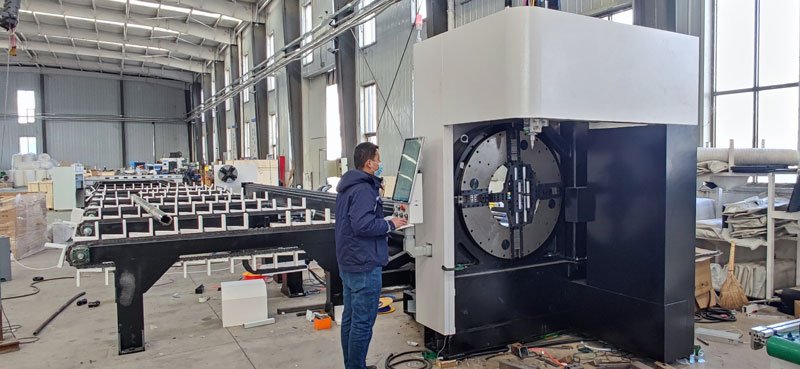

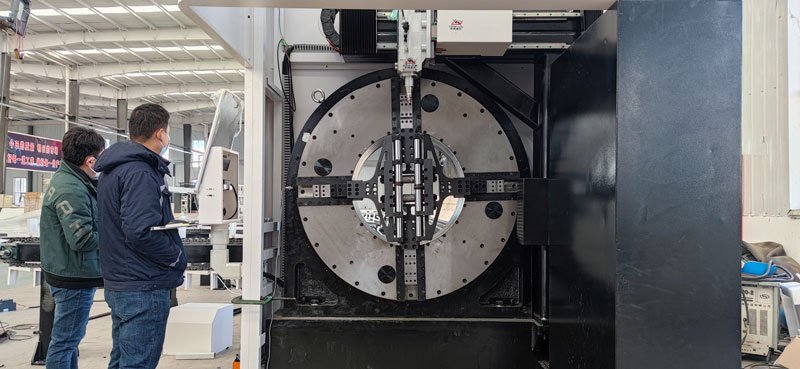

- Heavy duty laser pipe cutting machine

- Loading and unloading automatic laser pipe cutting machine

Heavy duty laser pipe cutting machine in industrial manufacturing

The role of these machines in industrial manufacturing is huge. They are critical in areas such as pipes, automotive frames and heavy machinery parts where large hollow structures are integral. The precision of laser cutting ensures that each part meets precise specifications, which is critical for safety and functionality, especially in industries such as aerospace and construction.

The integration of these machines into manufacturing processes marks a significant shift from traditional cutting methods, which are often less precise and more time-consuming. For example, in the automotive industry, parts must comply with strict safety standards, and the precision provided by heavy duty tube laser cutting machines ensures that each part meets these standards, reducing the risk of failure or accidents. The manufacturing process marks a significant shift from traditional cutting methods, which are often less precise and more time-consuming.

They’re not just for cutting; they’re used to create intricate designs and patterns on large tubing, which is critical in industries where aesthetics and functionality go hand in hand, such as custom car manufacturing or high-end construction projects.

By understanding the operation and significance of large scale tube laser cutting machines, companies in the industrial sector can better understand their potential impact on manufacturing processes and product quality. The ability to process a variety of materials with precision and efficiency makes them a valuable asset, changing the way large scale manufacturing is done.

Advantages of using large tube laser cutting machine

Afficiency

One of the most significant advantages of large pipe laser cutters is their efficiency. The machine can run continuously with minimal downtime, significantly reducing the time required for the production process. Their high-speed cutting capabilities allow for quick turnaround times, which is critical in industries where meeting project deadlines is critical.

Accuracy and efficiency

The precision provided by these machines is unparalleled. They can make dimensionally precise, complex cuts, which is critical for projects that require tight tolerances. This precision minimizes the need for additional finishing processes, further simplifying production and reducing overall costs.

Cost effectiveness

The initial investment cost of a large tube laser cutting machine can be significant, but the long-term savings are huge. Reduced material waste, reduced labor costs due to automation, and reduced need for secondary finishing processes all contribute to cost-efficiency. Additionally, the durability and longevity of these machines ensure a high return on investment over time.

Material processing versatility

Large tube laser cutters are not limited to a single type of material. They can handle a variety of materials with equal proficiency, including different grades of steel, aluminum and other metals. This versatility makes them a valuable tool in a variety of manufacturing environments, allowing businesses to expand their service offerings and adapt to various market needs.

The combination of efficiency, precision, cost-effectiveness and versatility makes large tube laser cutters a game-changer in industrial manufacturing. They represent significant technological advances that enable companies to optimize their production processes, reduce costs and improve product quality.

Factors to consider when purchasing a large tube laser cutting machine

Price

Price is a key factor It’s important to balance the cost of the machine with the features and functionality it offers. Less expensive models may not offer the longevity or accuracy required for industrial use, while the most expensive models may offer features that are unnecessary for your specific needs. Conducting a thorough cost-benefit analysis is critical to ensuring you are making a financially sound investment.

Configuration

The configuration of a large tube laser cutting machine determines its suitability for a specific task. Factors such as machine size, type of laser used (CO2, fiber optic, etc.) and its power output are critical. The machine’s ability to handle different pipe sizes and lengths should be consistent with your business’s current and future projects. Additionally, consider the machine’s compatibility with existing

Assess quality and reliability

Study the machine’s build quality, durability under continuous operation, and maintenance requirements. It’s also smart to read reviews and ask for recommendations from current users. Machines that break down frequently or require extensive maintenance can significantly disrupt production and increase costs.

Learn about technical specifications

Understanding the technical specifications is crucial to making an informed decision. Key specifications to consider include the machine’s cutting speed, accuracy, laser power and software capabilities. It’s also important to evaluate the level of ease of use and technical support provided by the These aspects will affect the integration of the machine into the production line and its overall performance.

Considering the price, configuration, quality, reliability, and technical specifications of a large tube laser cutting machine is crucial to making an informed purchasing decision. Together, these factors determine the machine’s value to your business and its potential to enhance your manufacturing capabilities.

Big tube laser cutting technology

Latest innovations

The field of large tube laser cutting is constantly improving. Recent innovations include enhanced laser power for faster cutting speeds and the ability to handle thicker materials. The integration of advanced software and automation technology is also notable, allowing for more precise control and efficient operation. These advancements not only improve the functionality of the machines but also make them more user-friendly and accessible to a wider range of industries.

Industry cases

The adoption of these cutting-edge machines in various industries highlights their growing importance. For example, in the automotive field, large tube laser cutting machines are used to manufacture complex parts with high precision, helping to create lighter and more fuel-efficient vehicles.

In construction, these machines help create intricate metal frames that enhance the aesthetics and structural integrity of buildings. Case studies from these industries show significant improvements in production efficiency, cost savings and product quality, highlighting the transformative impact of this technology.

Trends in large tube laser cutting technology indicate that precision, efficiency and versatility will be critical in the future. As these machines become more advanced and easier to use, they will play an increasingly important role in driving innovation and competitiveness in industrial manufacturing.

How to choose the right Big Pipe Laser Cutting Machine

Match machine capabilities to business needs

Choosing the right large tube laser cutter requires a deep understanding of your business’s current and future needs. Consider the type of project you are taking on, the materials commonly used and the throughput you want to achieve. The ideal machine should not only meet your current needs, but also be able to accommodate future growth and diversification.

Long term investment and ROI considerations

Investing in a large pipe laser cutting machine is a long-term commitment. It’s important to consider return on investment (ROI) when making your decision. Calculate potential gains in productivity, material cost savings from reduced waste, and the ability to take on more complex, higher-paying projects. Also consider the machine’s energy consumption and maintenance costs, as these will affect its overall cost-effectiveness in the long run. When you make a decision.

Making the right choice requires balancing technical capabilities, cost and the potential to drive business growth. By carefully evaluating these factors, you can ensure that your investment in a large tube laser cutter will not only enhance your current manufacturing processes, but also position your business for success in an increasingly competitive market.

Conclusion

To sum up, the right big laser cutting machine is more than just a purchase; it’s an investment in the future of your business. Given its efficiency, precision and versatility, this technology is crucial in industrial manufacturing, delivering significant advantages in productivity and innovation. Making smart choices can lay the foundation for lasting success in industrial manufacturing.