Stainless steel plate is a relatively common metal plate in the industrial market, how to cut stainless steel sheets is a common concern, if the amount of cutting stainless steel is relatively small, manual tools to cut stainless steel generally use hacksaws, angle grinders, blades, but these are the easiest way to cut stainless steel, can only be applied to the case of stainless steel plate is relatively small, the industrial market above the batch cutting, it is not applicable.

This article will tell you the best way to cut stainless steel sheet metal in some industrial markets.

Industrial market best way to cut stainless steel sheet metal

Sawing

Band saw refers to the use of composite high-speed steel band saw tools Cutting data is determined by the stability and ability of the saw blade and the type of steel being cut. For austenitic and duplex stainless steel below 75mm, the usual cutting speed is 20-35m/min. The feed speed is determined by the saw blade distance, cutting speed and the stability of the band saw.

Because the stainless steel plate is work-hardened, the forward feed must be protected, and the teeth on the saw bow cannot be pulled over the workpiece.

If friction occurs during the return stroke, the surface of the workpiece will be polished, which will shorten the tool life. At this time, a large amount of cutting lubricant needs to be added. The concentration of the emulsion is about 10-20%, and the flow speed is also higher than that of ordinary carbon steel cutting. speed.

Although bow saws and band saws can be used to cut narrow sheets, these two saws are typically used to cut medium-thick plate, steel sections, and tubing.

Waterjet cutting

The water pressure is 3000 to 4000 bar (bar), and the water consumption is only 4 liters per minute.

To cut stainless steel with abrasives such as aluminum oxide or silicon carbide, abrasive particles are injected into the jet of water before it reaches the steel. It can cut 20mm thick stainless steel with accurate cutting edges and clean and smooth cutting surfaces.

The heat generated by the cutting action is taken away by the water, and the metal temperature is only 50 to 60°C. This, coupled with the force generated by the jet water on the metal, can prevent deformation and improve cutting accuracy.

Step punching

Use round and triangular punches to punch a series of overlapping holes. It is obviously not possible to make a perfectly smooth cut with this process, but by using good tool design and overlapping the cuts, the cut edge can be made satisfactory for most purposes.

Portable stepper blanking machines are usually used to cut carbon steel sheets. If used to cut austenitic stainless steel, 60% more force is required.

Guillotine scissors

Most processing plants use this type of hand-operated shear. The blade length of this type of shear can reach 3m, but if the end of the shear is open, continuous shearing can be used to obtain a cut longer than the shear blade. But be careful not to cut out steps.

The thickness that the shear can cut when cutting soft steel must be reduced by two wire gauges when cutting ferritic steel. A shear that can cut up to 2 mm of mild steel must not cut ferritic steel when cutting. It needs to be reduced to less than 1.6mm and less than 1.2mm for austenitic steel, and the cutting edge clearance also needs to be reduced accordingly. The typical cutting edge clearance value for shearing austenitic stainless steel is 5%.

Trimming

Edge trimming uses a movable upper blade and a fixed lower blade, and uses a suitable blade gap to apply shearing force to metal plates of different thicknesses to cut and separate the plates according to the required size.

Disc shears

Disc shears work on the same basic principle as guillotine shears, but by using a disc blade they can make continuous cuts. Steel plants use several blades mounted on two shafts to slit wide steel coils. A pair of blades can also be used to cut single straight strips. Some shears can also move the blade sideways to cut wedge-shaped blanks during the shearing process, while others can rotate the cutter to cut round blanks.

Flame cutting:

The cost of cutting equipment is low and cutting thick metal plates is an effective method, but thin plate cutting still has drawbacks. Compared with plasma, flame cutting has a larger heat-affected zone and greater thermal deformation.

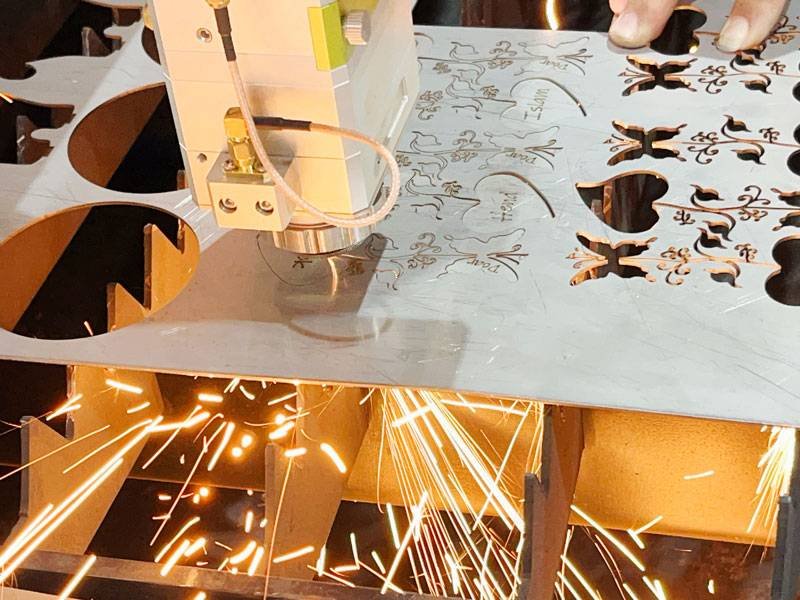

Laser cutting:

Laser cutting equipment can cut stainless steel plates less than 30 mm, and after adding oxygen to the laser beam, it can cut carbon steel 40 mm thick. However, after oxygen cutting, a thin oxide film will be formed on the surface.

- The 12000 power can cut the thickest plate at 35 thick.

- The 30,000 power can cut 85-100 pieces thick.

However, 12,000 and 20,000 are commonly used in the market. The higher the power of the equipment, the higher the price and the greater the cost.

Wire cutting:

It can also be called wire cutting. Developed on the basis of EDM punching and molding. It not only develops the application of EDM, but also replaces EDM’s punching and molding in some aspects.

Plasma cutting

The high-temperature plasma heat in the plasma cutting machine melts the metal in the cut of the workpiece, and the momentum of the high-speed plasma is used to remove the molten metal to form the cut.

It can cut thicker plates, but there are oxidized black edges and burrs. You have to do the edge milling yourself after you go back, because plasma cutting is prone to black edges and burrs, so the normal cutting allowance should be 5-10MM. The margin can also be added according to the customer’s own requirements. Although plasma cutting has black edges, the processing price is relatively cheaper.

Best tool to cut stainless steel

The best tools for cutting stainless steel will vary depending on the material you want to cut. For sheet materials no thicker than 18 gauge (the smaller the thickness, the thicker the metal), the best general shop tool is an electric shear. They have strong jaws that bite through metal, cutting 1/4-inch wide strips and leaving very clean edges. They can also cut curves.

Use sawing stainless steel, with stainless steel abrasive blades. This creates a lot of sparks, but it cuts fairly cleanly, especially A circular saw won’t cut curves, so you’ll have to switch to a jigsaw or grinder to handle curved corners.

Where scissors are bad is for making internal cuts, such as for sink cuts, because they have to start from the edge. The solution is to cut a hole (usually with a hole saw) large enough so that the scissors can get a good bite into the material.

Carbide blades cut stainless steel with jigsaw plates about 5/64 inch thick. Puzzles can be cut in longer straight lines (preferably with ruler guides), but are best used for narrow curves and internal cuts.

It may be easiest to make small cuts in steel plate or thicker materials such as stainless steel tiles with a grinder or rotary tool. Use an abrasive cutting wheel made of stainless steel. Traditional grinding wheels are more likely to overheat stainless steel and don’t cut as efficiently.

Best blade to cut stainless steel

Carbide cutting tools

Carbide cutting tools are one of the main tools for processing stainless steel. Their advantages are high hardness, good wear resistance, strong impact resistance, and the ability to maintain good cutting conditions and accuracy during high-speed cutting.

Ceramic knife

Ceramic cutting tools are a new type of cutting tool material. Their hardness and wear resistance are higher than those of carbide cutting tools, and they have better corrosion resistance. They can be used to process stainless steel, copper, aluminum and other materials. Ceramic cutting tools have a long service life and can cut at high speeds, making them suitable for production of large quantities of similar parts.

Drills, reamers and milling cutters

In addition to carbide and ceramic tools, drills, reamers and milling cutters are also commonly used when machining stainless steel for tasks such as drilling, keyholes and grooving. The manufacturing processes and materials of these tools are different, and the appropriate type needs to be selected according to the processing requirements when using them.

How to cut stainless steel with angle grinder

Choose the right cutting disc

Angle grinders usually use grinding wheel cutting discs for processing. Different types of stainless steel plates correspond to different types of cutting discs. For example, thicker stainless steel plates require larger thickness cutting discs (for example, 6 mm stainless steel plates require a diameter of 125 mm. cutting disc). The quality and specifications of the grinding wheel prevent accidents such as breakage.

Choose the right speed

For cutting discs of different materials and specifications, different rotation speeds need to be selected. When cutting stainless steel plates, the rotation speed is generally recommended to be 8000-10000 rpm. If the speed is too slow, rust will easily occur; if the speed is too fast, the cutting disc will break easily.

Cooling of machined surfaces

Stainless steel plates have relatively poor thermal conductivity and are prone to generating heat and smoke. In order to prevent the plate from deforming and ensure the cutting effect, spray coolant in time. Generally, water or special coolant for cutting machines can be used.

Security measures

Using an angle grinder to cut stainless steel plates may produce large splashes and noise. You need to wear protective glasses, masks, earplugs and other protective equipment, and pay attention to the ventilation of the working environment. In addition, when using the angle grinder, stability should be ensured to avoid buckling and rebound, thereby avoiding personal injury.

Cutting stainless steel with tin snips

Scissors are not suitable for cutting hard stainless steel because stainless steel has high hardness and toughness, which requires higher material and design for scissors.

If you need to cut stainless steel, you should use a special cutting tool, such as metal scissors, tin scissors or electric shears. At the same time, you need to pay attention to safety during use, choose a cutting tool suitable for the material, keep the knife edge smooth, and polish the sharp edge of the smooth stainless steel in time.

When using tools such as metal scissors, tin scissors, or electric shears to cut stainless steel, some precautions need to be taken to ensure the safety and efficiency of the work.

- Select a cutting tool that is suitable for the thickness and hardness of the material. If the strength is insufficient, it is easy to cut the knife edge.

- To keep the edge of the scissors smooth when cutting, lubricant needs to be added to reduce friction and protect the edge.

- After the cutting is completed, the sharp edges of the stainless steel need to be polished in time to avoid potential safety hazards.

How to cut stainless steel without discoloration

Gas cutting

A method that mixes high-pressure oxygen and fuel gas under high temperature and pressure to cause an oxidation reaction on the metal surface to achieve the purpose of cutting metal. During the cutting process of stainless steel sheet, it is necessary to select the appropriate gas cutting flame and control the cutting speed to avoid discoloration caused by overheating.

Laser cutting

A cutting method that focuses a high-density energy laser beam to a very small diameter and irradiates it longitudinally onto the metal material for cutting. Laser cutting does not directly contact the material, avoiding discoloration caused by the friction between the tool and the workpiece during the cutting process.

Water cutting

A cutting method that sprays high-pressure water onto the material to be cut and uses the high-speed jet of water to cut the material. It will not generate heat and will not cause discoloration of stainless steel. Water cutting can maintain high cutting accuracy and is suitable for cutting various stainless steel materials.

FAQ

How to cut thick stainless steel

For the cutting of thick stainless steel plates, three methods are generally used: fiber laser cutting, plasma cutting, and flame cutting. Different cutting methods can be selected according to different needs. Laser cutting is suitable for high-precision and fine processing, while plasma cutting and flame cutting are suitable for fast and low-cost scenarios.

Is Stainless Steel Hard to Cut

Stainless steel cutting is difficult, mainly because the strength of stainless steel types of different materials is inconsistent, so the corresponding force is relatively large when cutting, and it is not easy to plasticize.

Whats the Best Way to Cut Stainless Steel

This depends on the thickness of the board you are cutting, and whether you are cutting in batches or for small home use. The tools you choose are different.

Can Stainless Steel Be Cut

Yes, there are many ways to cut. Industrial equipment includes laser cutter, plasma cutter, flame cutter, water jet cutter, etc. For small ones, you can use knives, shears or manually.

How to Cut 1/4 Stainless Steel Plate

Regular stainless steel panels can be cut with simple power tools such as circular saws. If the board is thicker

More expensive cutting tools such as plasma cutters are required to cut 1/4-inch to 1/2-inch boards.