The rapid development of the industrial market has attracted people’s attention to environmental protection. Now Enviro Industrial Laser is widely popular in the remanufacturing industry because it is green and reducing carbon footprint and does not produce pollution.

What are Environmental Industrial Lasers?

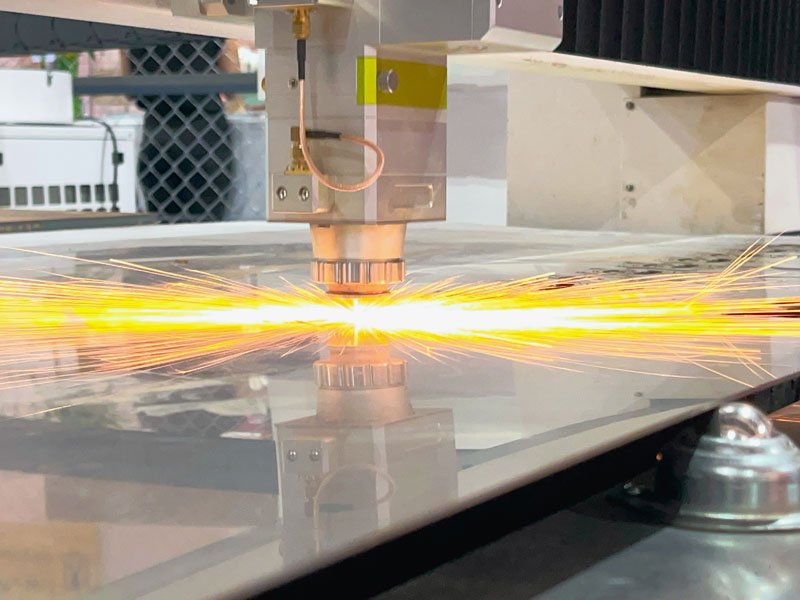

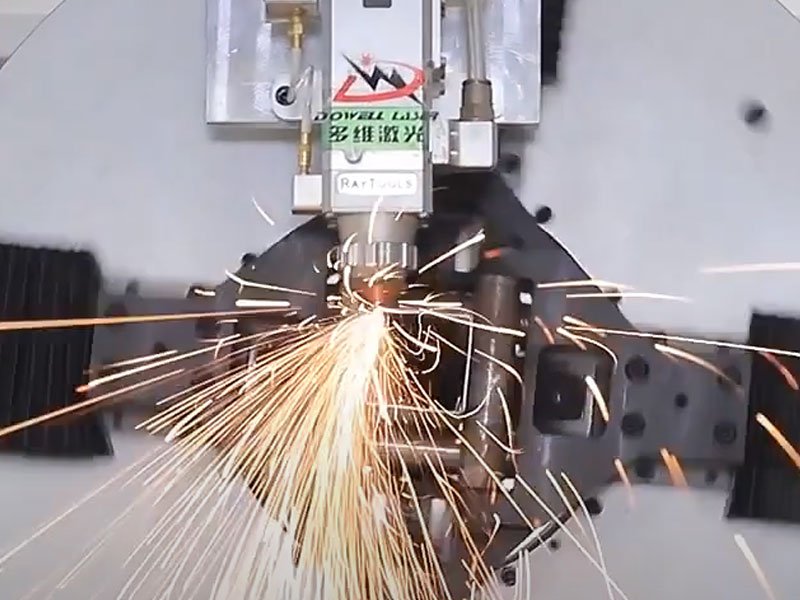

Industrial equipment that uses lasers as a source of heat. The high-energy heat generated is used to perform some chemical reactions, and processes such as cutting, welding, marking, engraving, rust removal, and decontamination are performed on the base material.

Industrial Laser Technology:

Photoelectricity is converted into laser energy, and the laser beam is focused into a small area through optical devices and directed at the workpiece. After melting, evaporating, and burning, it can achieve cutting, welding, cleaning, engraving, marking and other functions.Benefits of enviro industrial lasers in manufacturing.

Eco-Friendly Industrial Lasers VS Traditional Industrial Lasers

Enviro Industrial Laser has different characteristics from ordinary lasers in terms of light source, beam output, wavelength range, power, stability, imaging quality, etc. In different application scenarios, you can choose the appropriate laser model according to your needs.

Light source

Ordinary lasers mostly use gas or crystal materials as light sources, such as carbon dioxide lasers, Nd:YAG lasers, etc.

Eco-Friendly Industrial Lasers use optical fibers as light sources. Optical fiber materials mainly include erbium-doped, alumina, etc.

Beam output

The laser output of ordinary lasers is usually achieved by using reflectors, but this method is easily affected by external interference or vibration.

Enviro Industrial Laser uses optical fiber to transmit the beam.

Wavelength range

The wavelength range of ordinary lasers is narrow, while the wavelength range of Sustainable Industrial Laser is wider and can meet the needs of more fields.

Power

The power of Industrial Laser is lower than that of ordinary lasers, but in practical applications, fiber lasers are superior to traditional lasers in terms of energy conversion efficiency.

Stability

The light source of Eco-Friendly Industrial Lasers adopts an optical fiber structure, so the output is more stable and more resistant to interference

Image quality

The diameter of the optical fiber is small and the beam quality is good, so the imaging quality of Eco-Friendly Industrial Lasers is better and can better present details and contours.

Environmental Industrial Laser environmental protection

Energy saving, environmental protection and high efficiency

High electro-optical conversion efficiency, in terms of photoelectric conversion rate: fiber laser reaches 30%, YAG solid laser only 3%, CO2 laser 10%;

The gain medium in traditional lasers usually requires water cooling.

Fiber lasers use optical fibers as gain media, which have a large surface area/volume ratio and very good heat dissipation properties.

The closed all-fiber structure ensures the stability of the laser cavity. The cooling requirements are greatly reduced. Low-power fiber lasers only need to be air-cooled, replacing the water cooling requirements necessary for traditional lasers, thus saving electricity and water.

High stability and low maintenance cost

Operating costs are reduced. There are no optical lenses in the fiber laser cavity and it can be used

The maintenance interval of the fiber laser system can be 50% longer than that of the CO2 system, and the maintenance cost is 50% lower. It can save a lot of maintenance costs and time, improve work efficiency, thereby saving energy and costs.

Reduce waste and emissions:

With the development of the times, laser radar can accurately analyze the geographical location, pollution area, and frequency of occurrence of pollution sources, and speculate on the sources and causes of pollution, effectively improving the efficiency of air pollution control;

Laser removal that is more efficient and less expensive than traditional methods;

There are laser lightings that are brighter than LED lights, smaller in size, more energy-saving, have a longer irradiation distance, and are more power-saving;

There is also alternative electroplating technology that has become a consensus in the industry, and laser cladding technology is recognized by the market for its low cost, zero pollution, long life, and low energy consumption.

Enviro Industrial Laser Applications

Industrial lasers are widely used in automobile For example, in the automotive industry, industrial lasers are used to cut, weld and precision engrave automotive parts.

In the aerospace field, it can be used to process aircraft parts and cut metal conduits, cables and other equipment. In the field of electronic technology, it can be used in semiconductor processing, mobile phone screen cutting and other processes.

- Metal processing: Fiber laser is suitable for cutting and welding of stainless steel, aluminum alloy and other metal materials.

- Non-metal processing: Fiber lasers are also suitable for cutting and welding of non-metal materials such as plastics and ceramics.

- Leather textile: In the leather textile industry, fiber lasers can be used for cutting and engraving trademarks and patterns.

Cost-Effective Eco-Friendly Lasers for Industry

Environmentally friendly industrial lasers are a relatively new type of laser, and their manufacturing cost is much higher than that of traditional CO2 lasers.

- 1. The cost of the main equipment of the laser, including the price of hardware equipment such as laser light sources and optical fibers.

- 2. The cost of the laser control system, including the price of the laser controller, power supply, etc.

- 3. Laser processing system supporting equipment costs, including processing platforms, cooling systems, and other supporting equipment prices.

The cost of fiber lasers is relatively high, but with technological advancements and increasing market demand, the cost of fiber lasers is expected to gradually decrease in the future.

How to Choose the Right Enviro Industrial Laser

When selecting the right environmentally friendly laser, it is necessary to consider whether the supplier can provide effective product certification, whether it places more emphasis on research and development, and whether the price offered is competitive.

1. Power and beam of light quality:

Laser power is an important factor in determining the effect of industrial applications such as cutting and welding, while beam of light quality is related to machining accuracy and surface quality. When choosing a laser, consider the power and beam of light quality requirements.

2. Stability and maintenance:

Industrial production has high requirements for equipment stability and maintenance simplicity. Choosing lasers with high reliability and long maintenance intervals can improve production efficiency and reduce operating costs.

3. Supporting equipment compatibility:

Consider the compatibility of the industrial robots, motion control systems, and other equipment used to ensure the stable operation of the entire processing system.

4. Supplier product certification and environmental protection:

Pay attention to whether the laser has passed relevant product certifications (such as CE certification), and whether its operation meets environmental requirements.

Conclusion

The application of fiber lasers has been rapidly popularized. It is energy-saving, environmentally friendly, efficient and easy to combine with robots and intelligent control. In the future, enviro industrial laser technology will lead the manufacturing industry and be more environmentally friendly. If you want to explore Environmental Industrial Lasers together.