After investing significantly in fiber laser cutting equipment, customers face substantial losses if the fiber laser settings are not set correctly.

In this guide, we will provide essential insights into the correct fiber laser parameters that not only prevent financial setbacks but also significantly enhance the accuracy, precision, and overall work efficiency of laser cutting. Let’s dive into the key parameters to ensure optimal performance and maximize the return on your investment.

What is Fiber Laser?

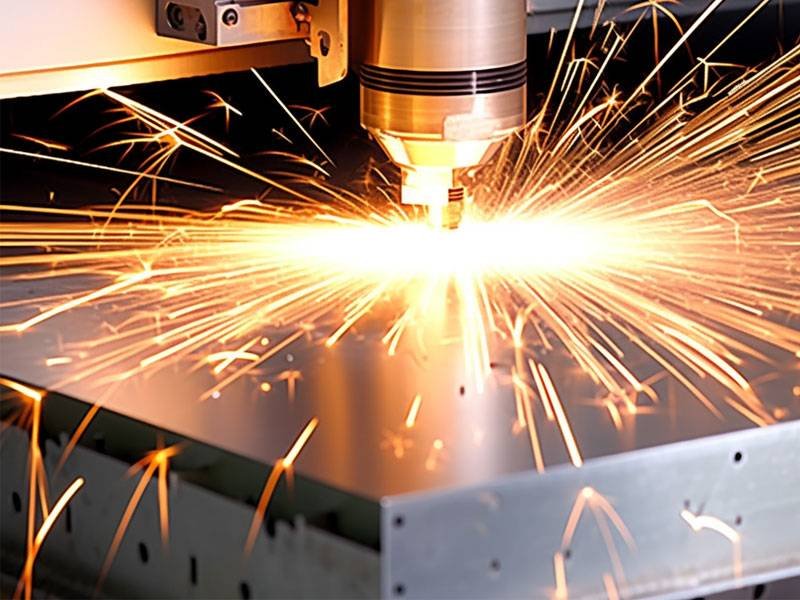

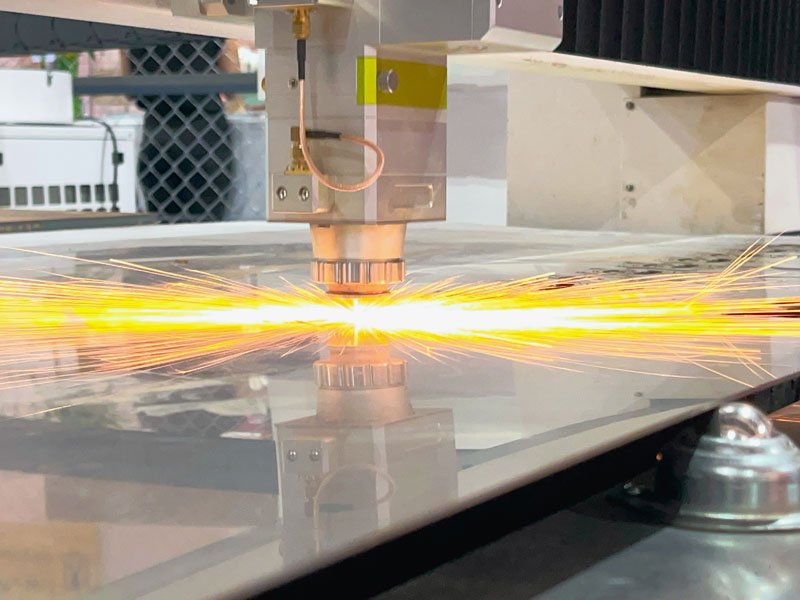

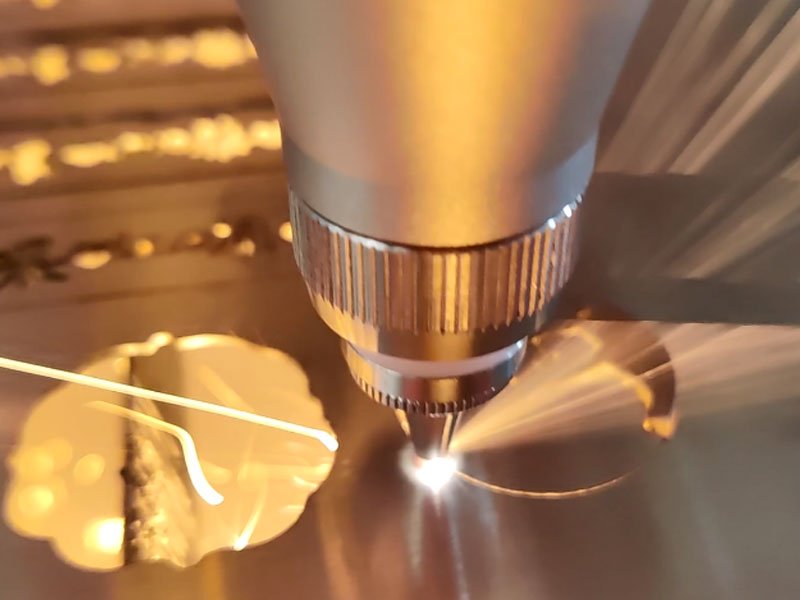

The high-energy laser beam generated by the fiber laser is focused on the surface of the workpiece and is cut by melting or evaporating the material at high temperature.

Fiber laser is a fiber-based solid laser with the characteristics of high efficiency, stability and reliability. With its advantages, laser everything parameters includes pump light source, fiber amplifier, fiber mirror, and laser output fiber.

Pump Light Source

The pump light source is the core component of the fiber laser, which provides energy to the excitation fiber and the dopants in the material to generate laser light. Commonly used pump light sources include semiconductor pump diodes, fiber-coupled laser diodes, etc. Semiconductor pump diodes are the most commonly used pump light sources.

Fiber Amplifier

Fiber amplifier is another key component of fiber laser and is used to amplify the laser light generated by the pump light source. The structure of the fiber amplifier includes doped fiber, pump light source and fiber reflector.

Fiber Optic Reflector

Fiber optic mirrors are mirrors that reflect laser light back to doped optical fibers. Their structures include lenses and reflective films.

Laser Output Fiber

The laser output fiber is an optical fiber that transmits the generated laser light to the desired location. Its structure is similar to that of ordinary optical fiber. The quality of the laser output fiber has a great impact on the output power and stability of the laser, so it is important to choose high-quality fiber.

What are Laser Cutting Parameters?

- Laser wavelength: The wavelength of light emitted by the laser, usually in nanometers (nm). Lasers of different wavelengths are suitable for different applications.

- Laser power: refers to the power output by the laser, usually in watts (W). The greater the power of the laser, the stronger its energy and irradiation capability.

- Laser pulse width: refers to the time width of the laser output pulse, usually in picoseconds (ps). The shorter the pulse width, the higher the energy density and irradiation accuracy.

- Mode: The mode of the laser can be single mode or multi-mode. The beam output by a single-mode laser is more collimated and suitable for applications requiring high precision, while the beam output by a multi-mode laser is looser and suitable for applications requiring large-area irradiation.

- Fiber laser frequency: refers to the repetition frequency of the laser output pulse, usually in kilohertz (kHz). The higher the repetition frequency, the faster the processing speed.

- Laser beam quality: refers to the quality of the laser output beam, usually measured by the M2 value. The higher the beam quality, the better the beam can be focused.

- Laser stability: refers to the stability of the laser output power, usually expressed in percentage (%). The higher the stability of the laser, the smaller the fluctuation range of its output power.

- Laser life: refers to the service life of the laser, usually in hours (h). Longer laser life results in less frequent equipment maintenance and replacement.

Why Are Fiber Laser Settings so Important?

Improve cutting efficiency: Reasonable settings can shorten processing time and improve production efficiency.

Ensure cutting quality: Correct fiber laser cutting settings can obtain high-quality cutting surfaces and reduce rework rates.

Extend equipment life: Avoid excessive parameter settings to extend the service life of the equipment.

Fiber Laser Settings That Affect Cutting Quality:

Cutting height, cutting nozzle model, focus position, cutting power, cutting frequency, cutting duty cycle, cutting air pressure and cutting speed.

Hardware conditions include: protective lens, gas purity, plate quality, focusing lens and collimating lens.

Fiber Laser Cutter Settings for Different Materials

Metallic Materials

For metallic materials, different types (such as stainless steel, aluminum, and copper) require different settings. Stainless steel generally requires higher power and moderate cutting speeds, while aluminum can be cut at higher speeds.

- Stainless steel: Stainless steel has high reflectivity and requires higher power and appropriate auxiliary gas.

- Carbon steel: Carbon steel is relatively simple to cut, but attention should be paid to the matching of cutting speed and power.

- Aluminum alloy: Aluminum alloy has good thermal conductivity, and attention should be paid to the focus position and cutting speed

- Thin plates, thick plates, and pipes: The cutting parameters will be different for materials of different thicknesses.

When adjusting parameter data when cutting stainless steel, modify the laser cutting machine settings in a targeted manner according to the problems that often occur when cutting stainless steel plates.

The slit width is generally around 0.5mm, which is related to factors such as the nature and thickness of the material to be cut, laser power, focal length and focus position, laser beam diameter, injection gas pressure and flow rate, etc.

| Factor | Laser Power | Gas Pressure | Material Thickness | Cutting Speed (for example) |

|---|---|---|---|---|

| Increase/Decrease | Increase | Increase | Decrease | Varies based on material |

| Example Scenario | 3000W | High pressure | 6mm Stainless Steel | 3m/min |

| Example Scenario | 3000W | High pressure | 8mm Stainless Steel | 1.2m/min |

| Example Scenario | 3000W | High pressure | 6mm Aluminum | 2m/min |

Non-metallic Materials

Non-metallic materials such as plastics and wood also have specific requirements when laser cutting. Acrylic materials generally require lower power and higher frequencies to prevent burning, while wood requires moderate power and speed to ensure a clean cut.

- Non-metallic materials: Such as wood, plastic, etc., laser power and cutting speed need to be adjusted

| Material | Laser Power (W) | Cutting Speed (mm/min) | Focal Length (mm) | Frequency (kHz) | Notes |

|---|---|---|---|---|---|

| Stainless Steel | 100 | 500 | 1.5 | 20 | High reflectivity, requires higher power |

| Aluminum | 150 | 600 | 1.5 | 25 | Good thermal conductivity, faster cutting speed |

| Copper | 200 | 300 | 1.5 | 30 | Good thermal conductivity, but easily oxidized |

| Acrylic | 50 | 800 | 2.0 | 10 | Non-metallic material, faster cutting speed |

| Wood | 40 | 1000 | 2.0 | 5 | Fast cutting speed, but easy to produce dust |

Gas Fiber Laser Cutting Settings

Common cutting gases: oxygen, nitrogen, air, argon, etc.

The Impact of Different Gases on Cutting Effect:

- Oxygen: supports oxidation reaction, fast cutting speed, but easy to produce oxide layer.

- Nitrogen: inert gas, protects the cutting surface, suitable for materials such as stainless steel.

- Air: between oxygen and nitrogen, suitable for a variety of materials.

- Argon: protective gas, used for cutting active metals such as aluminum alloy.

- Air pressure setting: If the air pressure is too low, the cutting effect is poor; if the air pressure is too high, it is easy to produce spatter.

1000w-15kw Fiber Laser Cutting Parameters

| Laser Power (W) | Material | Thickness Range (mm) |

|---|---|---|

| 1000w | Carbon Steel | 0.8-10 |

| 1000w | Stainless Steel | 0.8-5 |

| 1000w | Aluminum Alloy | 0.8-3 |

| 1000w | Brass | 1-3 |

| 1500w | Carbon Steel | 1-16 |

| 1500w | Stainless Steel | 1-6 |

| 1500w | Aluminum Alloy | 1-4 |

| 1500w | Brass | 1-3 |

| 2000w | Carbon Steel | 1-20 |

| 2000 | Stainless Steel | 1-8 |

| 2000w | Aluminum Alloy | 1-6 |

| 2000w | Brass | 1-5 |

| 3000w-3300w | Carbon Steel | 1-22 |

| 3000w-3300w | Stainless Steel | 1-10 |

| 3kw-3300w | Aluminum Alloy | 1-8 |

| 3kw-3300w | Brass | 1-6 |

| 4kw | Carbon Steel | 1-25 |

| 4000w | Stainless Steel | 1-15 |

| 4kw | Aluminum Alloy | 1-10 |

| 4000w | Brass | 1-8 |

| 6000w | Carbon Steel | 1-30 |

| 6000w | Stainless Steel | 1-20 |

| 6kw | Aluminum Alloy | 1-20 |

| 6kw | Brass | 1-12 |

| 8000w | Carbon Steel | 1-40 |

| 8000w | Stainless Steel | 1-30 |

| 8000w | Aluminum Alloy | 1-30 |

| 8000w | Brass | 1-16 |

| 10000w | Carbon Steel | 1-45 |

| 10000w | Stainless Steel | 1-40 |

| 10000w | Aluminum Alloy | 1-40 |

| 10000w | Brass | 1-20 |

| 12000w | Carbon Steel | 1-50 |

| 12000w | Stainless Steel | 1-45 |

| 12kw | Aluminum Alloy | 1-45 |

| 12kw | Brass | 1-20 |

| 15000 | Carbon Steel | 1-60 |

| 15000 | Stainless Steel | 1-50 |

| 15kw | Aluminum Alloy | 1-40 |

| 15kw | Brass | 1-20 |

Cutting Effect Is Not Good, How to Check the Laser Settings

- Cutting height (it is recommended that the actual cutting height is between 0.8~1.2mm). If the actual cutting height is inaccurate, calibration is required.

- Cutting nozzle. Check whether the model and size of the cutting nozzle are used correctly. If it is correct, check whether the cutting nozzle is damaged and whether the roundness is normal.

- Optical center It is recommended to use a cutting nozzle with a diameter of 1.0 to check the optical center. The light spots produced in this way are small and easy to observe.

- Protect the lens. Check whether the protective lens is clean and requires no water, no oil, and no residue. Sometimes the protective lenses may fog up due to weather conditions or too cold air.

- Focus Check whether the focus is set correctly. If it is an automatic focusing cutting head, you must use the APP to check whether the focus is correct.

- Modify laser parameters

Difference Between Different Wavelengths in Laser Parameters:

The wavelength of red laser is generally between 630nm and 680nm, and the light emitted is red. It is also the most common laser (mainly used in the field of medical mammography, etc.);

The wavelength of green laser is generally around 532nm (mainly used in the field of laser ranging, etc.);

The wavelength of blue laser is generally between 400nm-500nm (mainly used in laser surgery and engraving fields, etc.);

Ultraviolet laser is between 350nm-400nm (mainly used in biomedicine and material processing fields);

How Fiber Laser Deep Engraving Settings

Before using a laser engraving machine, you must first understand its basic operation. Generally speaking, the operation panel of a laser engraving machine includes a power button, start/stop button, mode selection button, depth adjustment knob, etc. Users need to be familiar with the functions and operation methods of these buttons so that the engraving process can proceed smoothly.

Choose the Appropriate Engraving Mode

The engraving modes of laser engraving machines include outline engraving, fill engraving, text engraving, etc. Users need to choose the appropriate engraving mode according to actual needs in order to obtain better engraving effects.

Adjust Depth Adjustment Knob

The depth adjustment knob is one of the most important control parts of the laser engraving machine. Users need to adjust the depth according to the actual situation in order to obtain the ideal engraving effect.

When Adjusting the Depth, Pay Attention to the Following Points:

- Adjust the depth range: Different laser engraving machines have different depth ranges, and users need to adjust them according to the actual situation.

- Adjust depth accuracy: The accuracy of the depth adjustment knob is an important factor affecting the engraving effect. Users need to adjust it according to the actual situation.

- Avoid over-engraving: Over-engraving will cause the material to become thin or damaged, affecting the engraving effect and quality. Users need to pay attention to controlling the depth and avoid over-carving.

Common problems and solutions

| Issue | Possible Cause | Adjustment Suggestion |

|---|---|---|

| Rough Cutting Edge | Cutting speed is too fast | Reduce cutting speed |

| Uneven Cutting | Incorrect focal position | Adjust focal position to the center of the material |

| Insufficient Cutting Depth | Insufficient laser power | Increase laser power |

| Material Burned | Cutting speed is too slow or laser power is too high | Increase cutting speed or decrease power |

Conclusion

Fiber laser cutting settings is a comprehensive technology that requires operators to have certain theoretical knowledge and practical experience. This article only makes a preliminary discussion on the settings of laser cutting machines, hoping to provide some reference for users. In actual production, it is also necessary to make flexible adjustments according to specific circumstances.

Related articles

- Interpreting The Fiber Laser Cutting Speed Chart And Thickness Chart

- Laser Cutting Operators: A Guide to Fiber Laser Protection Glasses

- Laser Cutter Safety Comprehensive Standards Guidelines

- Laser Cutting Speed And Power Chart : 6kw Vs 12kw Laser Cutter

- Factors Influencing Fiber Laser Cutting Machine Parameters