With the continuous development of the pipe cutting market demand, the industrial market has an increasing demand for the cutting of section steel, angle steel, and channel steel. Therefore, the advent of H beam laser cutting machine can help people solve the cutting needs of heavy and large metal pipes.

What is a Sectional Steel Laser Cutting Machine

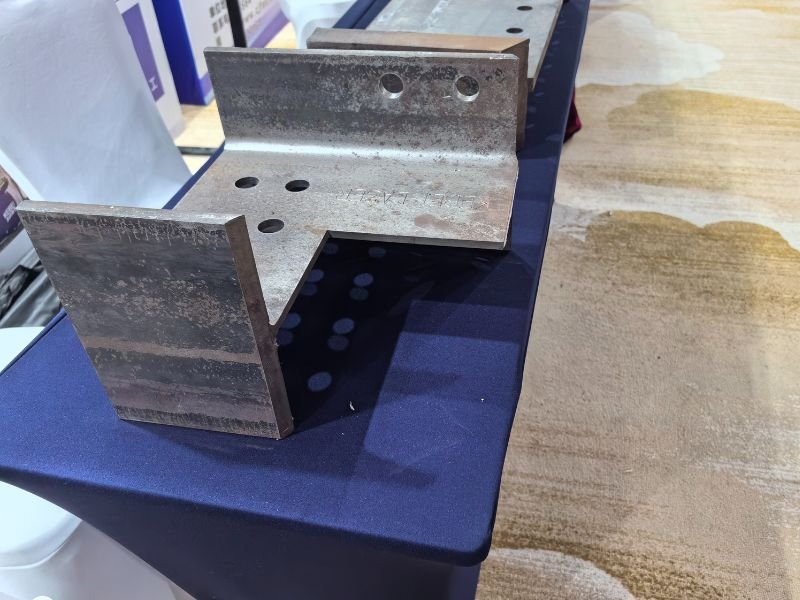

The profile steel laser cutting machine is a special laser cutting machine designed for efficient processing of steel beam profiles such as I-beams and H-beams. The cutting speed is fast and the precision is high. In addition, a loading and unloading device can be configured to meet batch processing requirements.

How Much Sectional Steel Laser Cutting Machine Cost

Entry level (around $15,000 to $50,000): These machines are suitable for basic cutting needs on steel beams and profiles. They may have lower laser power and more manual operation.

Mid range (around $50,000 to $200,000): Offering more advanced features like automation and higher-powered lasers, these machines provide increased productivity and precision for diverse cutting tasks.

High end (around $200,000 to $500,000): Boasting extremely high-powered lasers (10-30 kW), advanced automation systems, and specialized cutting heads, these industrial-grade machines are ideal for heavy-duty applications and maximum efficiency.

Steel Profile Laser Cutting Machine Features

- Steel beam cutting, drilling, and laser marking all-in-one machines provide fast and accurate solutions for processing steel structural components.

- With strong compatibility, it can handle steel beams of various sizes and profiles, including I-beams, H-beams, etc., to meet a variety of metal manufacturing needs.

- High-quality laser cutting, using fiber laser technology, has no burrs, high precision, and no stress. The small incision width ensures cutting accuracy.

- Designed specifically for steel beam cutting, equipped with a dedicated cutting head and software to optimize the cutting process and improve efficiency.

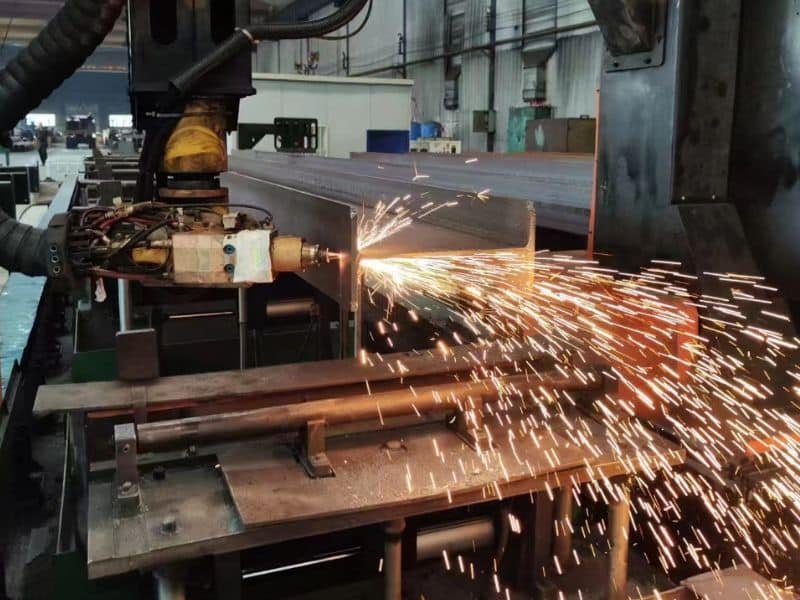

- Supports automation functions and can be integrated with switching stations, robots, etc. to achieve efficient production.

Advantage

- Efficiency: By cutting, drilling, and marking simultaneously, throughput is significantly increased. Fabricate complex steel structures faster than ever.

- Universal Beam Handling: This versatile machine handles a variety of steel beam sizes and shapes, including I-beams, I-beams, and various profiles. No need for multiple machines, just one that seamlessly adapts to your project needs.

- Precision Laser Power: Our high-precision laser cutting delivers clean, accurate cuts with minimal kerf width. This minimizes material waste and maintains the structural integrity of the steel components.

- Simplified workflow: Specialized cutting heads and software ensure optimized cuts specifically for steel beams and profiles. Experience a tailor-made process that eliminates unnecessary steps.

- Automation: Increase your productivity by integrating with automated features like exchange tables and robot processing. This allows for a smooth, uninterrupted workflow.

- Reduced downstream processing: Laser-cut parts require minimal assembly preparation compared to traditional methods. This means significant time and cost savings.

- Environmentally Friendly Manufacturing: Minimizes environmental impact through a clean cutting process that produces minimal waste and emissions.

Application areas:

H shaped steel production lines can be used in various fields such as construction, bridges, railways, vehicles, ships, machinery, electronics, etc., while heavy steel production lines are mainly used in construction, bridges, equipment manufacturing, electric power, petrochemicals and other fields.

- Steel structure manufacturing

- Building Construction

- Machine made

- Shipbuilding

- Car manufacturer

- Other metal processing industries

Safety When Using a Channel Steel Laser Cutting Machine

- Expert Training: Only specially trained and authorized personnel operate the machine. This ensures a thorough understanding of the high-powered laser and its potential hazards.

- Laser Safety Zone: The work area is clearly demarcated with warning signs. Access is restricted to authorized personnel only, minimizing the risk of accidental exposure.

- Protective Gear: Operators wear industry-standard laser safety glasses and protective clothing. This shields them from both direct and reflected laser beams.

- Fire Safety First: The work area is free from flammable materials. A fire extinguisher is readily available to address any potential ignition.

- Clean Air Advantage: A robust ventilation system removes any toxic fumes or particulates generated during laser cutting. This safeguards operators’ health.

- Monitoring and Documentation: Operators never leave the machine unattended. A detailed log tracks usage and any issues, ensuring early detection of potential problems.

- Preventative Maintenance: Regular cleaning and inspection minimize dust buildup, a major fire risk. This proactive approach keeps the machine functioning optimally.

- Manufacturer‘s Guidance: Strict adherence to the manufacturer‘s safety instructions and operating parameters is mandatory. This ensures the machine is used as intended, promoting long-term safety.

If you want to know more product information about steel structure laser cutting machines, you can consult us to get the latest product quotation.

FAQ

What pipes can be cut by the steel laser cutting machine?

It can process square tubes, round tubes, waisted round tubes, oval tubes, I-beams, H-shaped steels, angle irons, channel steels and some special-shaped tubes made of carbon steel, stainless steel, aluminum alloy and other metal materials.

How powerful is the I-beam laser cutting machine?

6000w 12000w 15000w 20000w 30000w 80000w

What is the cutting accuracy of I Beam Laser Cutting Machine?

±0.05mm