The advent of laser cutting technology has changed the difficulty of cutting in the industrial market, especially in manufacturing. Many customers have a question in the early stage of purchasing a laser cutting machine: How Deep can a Laser Cutter Cut? This article will bring you a detailed understanding of Laser Cutting Thickness.

Into laser cutting

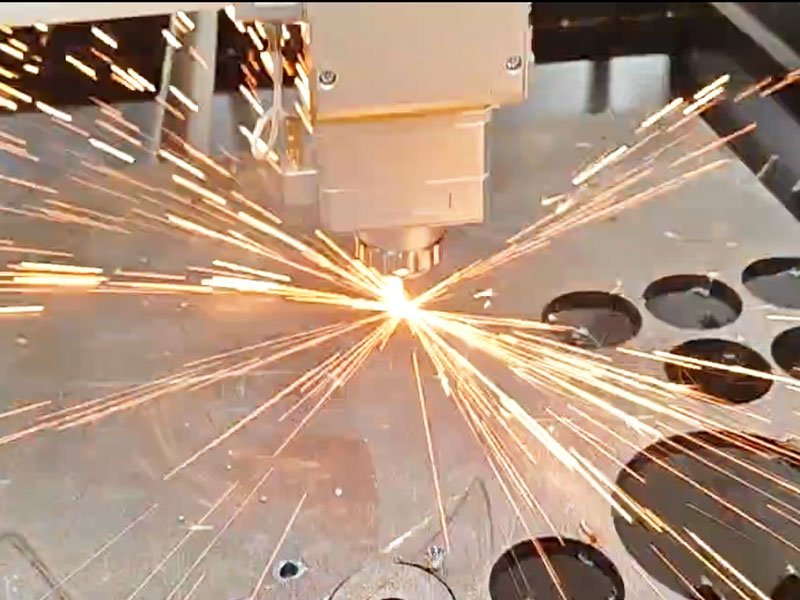

Laser cutting technology uses a high-energy laser beam to precisely fix the point on the plate, and uses the heat generated to quickly evaporate or melt, so that the plate can be cut into any graphics without limitation. It is a non-contact technology.

How thick can a laser cutter cut

Different models and similar machines can cut to different depths. The depth of metal laser cutter cutting metal and wood laser cutter cutting wood are also different.

Metal laser cutting machine cutting depth

For example, a 1000w fiber laser cutting machine can cut carbon steel plates of about 10mm. It is more difficult to cut stainless steel. To increase the cutting thickness, edge effects and speed can be sacrificed.

Carbon steel 36mm (steel plate quality is good, speed can reach 650mm/min). If the 36mm steel plate is made of high-quality materials, the machine performance is good, the graphics are not complicated, and the cutting quality is still very good.

The key is that the speed is not fast, and it is more reasonable to use a plasma cutting machine or a flame cutting machine. 25mm stainless steel (when using high-pressure nitrogen as auxiliary gas, the speed is about 400mm/min);

Chinese users usually target laser cutting, with mild steel below 25mm and stainless steel below 16mm.

The laser cutting thickness limit of the higher power 60kw is as high as 200mm-300mm. The higher the power, the higher the laser cutter cutting depth.

Related articles:

- Comprehensive Best Laser Cutting Materials List

- Ultimate Guide : How Thick Can A Laser Cutter Cut Steel

- Fiber Laser Cutting Problems And Solutions

- Interpreting The Fiber Laser Cutting Speed Chart And Thickness Chart

Laser cutter wood

The depth of laser engraving on wood is generally not deep within 5mm. This is because the power of wood laser cutting is small. Slowing down the cutting speed will cause the wood to burn. During the specific operation, you can try to use large-sized lenses and use repeated cutting methods.

Laser cutter wood thickness

When a laser cutting machine cuts wood boards, the maximum cutting thickness is affected by many factors. Factors including laser power, laser beam density, wood board material, board thickness, etc. will all affect the cutting effect. Usually wood cutting laser can cut wood boards with a thickness of about 10mm, but high-power and high-density laser beams can cut thicker boards.

Laser cutting depth influencing factors

Fiber laser power:

The higher the power, the thicker the cut sheet.Industrial laser cutting machine power 1000w-30kw.

| Stainless Steel | Carbon Steel | |||

| Laser Power | Cut Depth (mm) | Cut Speed (m/min) | Cut Depth (mm) | Cut Speed (m/min) |

| 1000w | 4 | 1.2 | 12 | 0.7 |

| 1500w | 6 | 0.8 | 16 | 0.5 |

| 2000w | 10 | 0.5 | 20 | 0.4 |

| 3000w | 12 | 0.5 | 22 | 0.5 |

| 4000w | 12 | 0.8 | 22 | 0.5 |

| 6000w | 14 | 0.9 | 22 | 0.5 |

laser cutting thickness and speed chart

Cutting material:

Different materials have different reflections on laser energy, and also have an impact on the depth of cutting.

Focus size:

The smaller the focus size, the more concentrated the laser light source and the deeper the cut.

Cutting speed:

The slower you move, the longer it takes for the energy to vaporize and the deeper the cut

Conclusion

There are many factors involved in the cutting depth of a laser cutting machine. If you want to know specific information, you can consult a laser cutting machine professional – Dowell laser or a laser cutting machine manufacturer to obtain the most accurate information.