For many people who want to pursue a career as a welder, understanding the different types of welding processes is the most basic first step, because there are many different welding processes on the market, among which there are generally 4 main types of welding that you must master.

Which ones are the easiest welding to learn and how to choose the most suitable welding equipment. I hope this article can Help you.

Purpose of welding

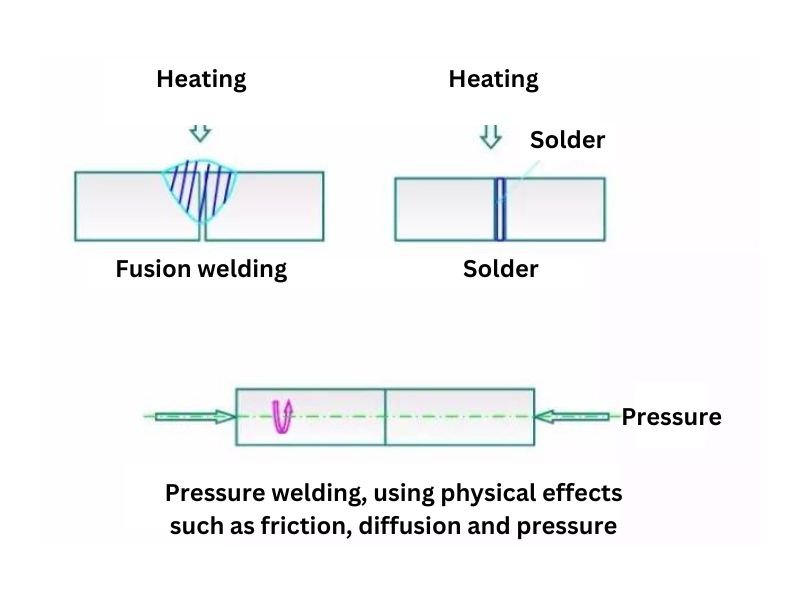

Welding is a technology in which different materials are heated or pressurized and a welding wire is added under a specific environment to combine the two objects and form an indivisible whole.

In What Fields Does Laser Welding Application Apply

Most common 4 different types of welding machines

Welding equipment is a type of equipment used for welding processes between metal sheets. According to different methods and working principles, it is divided into the following categories.

Arc welding equipment:

The most common welding equipment on the market, the high temperature of the arc generates energy to melt the material of the welder. Commonly used equipment include handheld arc welders, submerged arc welders, argon arc welders, etc.

Arc welding equipment is widely used in

Gas welding equipment:

Gas welding equipment mainly uses the high temperature generated by gas combustion to melt welding materials. Common gas welding equipment includes oxyacetylene welding machines, oxygen gas welding machines, etc.

Gas welding equipment has important applications in some special welding requirements, such as aerospace, petrochemical and other fields.

Welding robot:

With the development of industrial automation, welding robots are increasingly used in various industries. Welding robots can achieve efficient and precise welding operations, improving production efficiency and product quality. Common welding robots include multi-jointed robots, parallel robots, etc.

Welding automation equipment:

Welding automation equipment includes welding workstations, welding workbenches, welding automatic lines, etc. These devices realize welding operations through automation, improving production efficiency and work safety. Welding automation equipment is widely used in automobile manufacturing, electronic manufacturing, metal manufacturing and other industries.

Different types of welding processes techniques

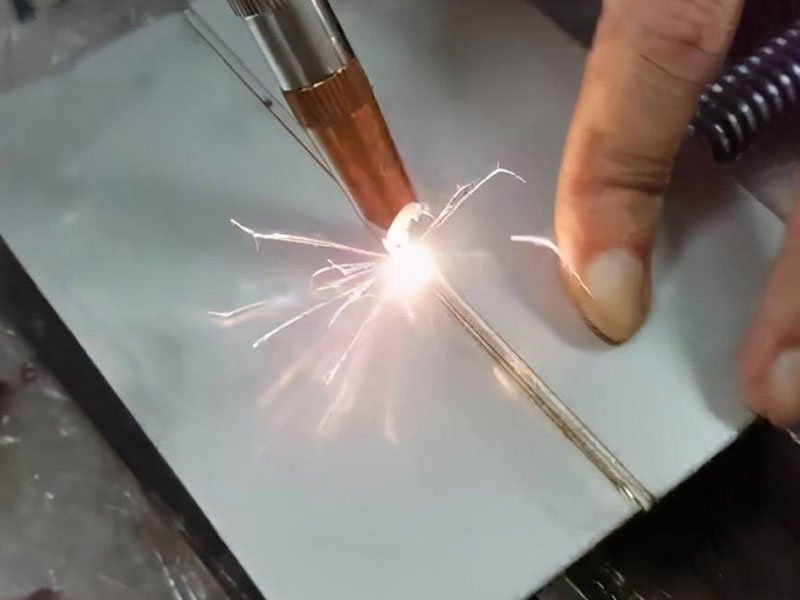

Laser welder

This method uses the heat generated by the laser to perform precision welding between metals, mainly by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse to melt the workpiece and form a specific molten pool.

Arc welding

Electrode arc welding is one of the most basic skills for welders. If the skills are not mastered properly, the welded seams will have various defects.

Submerged arc welding

Submerged arc welding is a welding method that uses an electric arc as a heat source. Due to the large penetration depth of submerged arc welding, the productivity and welding quality are good: because it is protected by slag, the molten metal does not come into contact with the air, and the degree of mechanized operation is high, so it is suitable for welding long welds of medium and thick plate structures.

MIG Welding Machine

The arc welding method in which external gas is used as the arc medium and protects the metal droplets, welding pool and high-temperature metal in the welding zone is called melting electrode gas shielded arc welding. The inert gas (Ar or He) shielded arc welding method using solid wire is called molten extremely inert gas shielded welding, or MIG welding for short.

Argon arc welding

Argon arc welding uses argon in an inert gas to form a protective zone around the molten pool and isolate the air to form the weld.

Gas welding

Gas welding is to use flame to heat the metal and welding wire at the connection of metal workpieces to melt them to achieve the purpose of welding. Commonly used combustible gases are mainly acetylene, liquefied petroleum gas, hydrogen, etc., and the commonly used combustion-supporting gas is oxygen.

Secondary protection welding

Carbon dioxide gas shielded welding. Carbon dioxide gas shielded welding is one of the welding methods. It is a method of welding using carbon dioxide gas as a shielding gas. In terms of application, the operation is simple and suitable for automatic welding and all-round welding.

Friction welding

Friction welding refers to a method of welding by using the heat generated by friction on the contact surface of the workpiece as a heat source to cause plastic deformation of the workpiece under pressure.

Friction welding usually consists of the following four steps:

- Mechanical energy is converted into thermal energy;

- Plastic deformation of materials;

- Forging force under thermoplasticity;

- Intermolecular diffusion and recrystallization.

Ultrasonic welding

Ultrasonic welding uses high-frequency vibration waves to transmit to the surfaces of two objects to be welded. Under pressure, the surfaces of the two objects rub against each other to form fusion between the molecular layers.

Ultrasonic welding system components: ultrasonic generator, transducer, horn, welding head trio, mold and frame.

Soft soldering

Brazing uses a metal material with a lower melting point than the base metal as the filler metal. The weldment and the filler metal are heated to a temperature higher than the melting point of the filler metal and lower than the melting temperature of the base metal. The liquid filler metal is used to wet the base metal, fill the joint gap and A method of connecting weldments through mutual diffusion with the base metal.

What are the different types of welding methods

Overhead welding

Overhead welding is less efficient than other position welding.

For bottom welding of butt welds, when the thickness of the weldment is less than or equal to 4mm, type ⅰ groove is used, and a welding rod of φ 3.2mm is selected, and the welding current should be moderate;

When the welding thickness is ≥ 5mm, multi-layer multi-pass welding should be used.

Flat welding

The weld metal mainly relies on the excess of self-weight to the weld pool, and the shape of the weld pool and the weld pool metal are easy to maintain and control.

Vertical welding

The welding productivity is lower than that of flat welding. When welding the cover layer, the shape of the weld surface is determined by the method of strip transportation. Crescent-shaped strip can be used for slightly higher weld surface requirements;

Serrated strips can be used for flat surfaces (the middle concave shape is related to the pause time)

Horizontal welding

Use other groove butt horizontal welding, the gap is small, the bottom welding can be used linear strip;

When the gap is large, a reciprocating linear strip should be used for the bottom layer. When other layers are welded in multiple layers, an oblique circular strip can be used. When multi-layer and multi-pass welding, a linear strip should be used.

Welding processes chart

What are the types of welding materials?

Materials consumed during welding:

Welding rods, welding wires, flux, shielding gas, electrodes, flux, etc.

Welding materials:

Steel, Aluminum, Stainless Steel, Cast Iron, Copper, Titanium Welding

Welding equipment configuration and protective

- Welding Machines

- Welding Helmets

- Welding Gloves

- Welding Rods

- Welding Wires

- Welding Gas

Welding Safety

Welding Safety Gear

Before performing welding operations, welders should wear appropriate personal protective equipment, including welding helmets, protective masks or goggles, fire-resistant gloves, fire-resistant clothing, fire-resistant shoes, etc.

Welding safety precautions

Before performing electric welding operations, the work area should be cleaned to ensure that there are no flammable materials, combustible gases, and other dangerous items around. Work areas should have adequate ventilation and warning signs to alert others to their attention.

Tig welding vs arc welding

| Aspect | MIG Welding | TIG Welding |

|---|---|---|

| Process Type | Semi-automatic or automatic welding process | Manual welding process |

| Gas Protection | Inert gas (e.g., argon) to shield the welding area from oxygen and impurities | Inert gas (typically pure argon) for shielding the welding area |

| Applications | Widely used in manufacturing, including automotive, metal structure fabrication, and welding repairs | Commonly used in applications requiring high-quality welds, such as aerospace, shipbuilding, and high-purity piping |

| Advantages | High efficiency, high speed, easy to learn and operate | High-quality welds, minimal spattering, suitable for precision welding and complex-shaped workpieces |

| Disadvantages | May produce spatter during welding, relatively lower weld quality | Requires high skill levels, slower welding speed |

Global Welding Certification List

International welding system ISO 3834 certification

ISO 3834 welding system certification requires It is based on ISO 9001 and combined with actual welding application conditions.

ISO 9606 International Welder Certificate

International qualification ISO 9606/EN 287 welder training and examination training, welder training for electrode arc welding, semi-automatic CO2 gas shielded welding, and manual tungsten arc welding according to ISO 9606/EN 287 standards.

Welders can be divided into four categories according to welding methods

Gas welding welders, stick arc welders, gas tungsten inert gas arc welders and gas metal arc welders.

Each type of welder can be divided into three levels, namely: fillet welder, plate welder and pipe welder. Each level can be trained and tested separately.

Welding procedure qualification WPQR

Welding Procedure Qualification Record (WPQR) is a test process and result evaluation conducted to verify the correctness of the proposed welding process or to assess the welder’s ability.

EN1090 welding certification

EN1090 is a standard for steel structures under the construction and building materials regulations CPR (Regulation (EU) No 305/2011) in CE certification. It is an assessment of the quality control capabilities of steel (aluminum) structure To ensure that the steel (aluminum) structure has sufficient mechanical resistance, stability, usability and durability.

What welding does not require gas

Manual arc welding

The welder uses a hand-held electrode to contact the workpiece, and the arc generated between the electrode and the workpiece melts the surface of the workpiece to achieve welding. Since there is no gas protection, welding must be completed in a short time to prevent oxidation.

Manual arc welding has the advantages of easy operation and low equipment burden, but it requires a high skill level and rich practical experience to master.

MIG gas-free shielded welding

MIG gas-free shielded welding is also called self-shielded welding. It does not require the use of argon or other rare gases to protect the weld, but uses the chemical reaction of flux-cored wire to protect the welding area.

MIG gas-free shielded welding is suitable for welding items that are difficult to form, such as heat sinks, etc. At the same time,

Flux cored wire welding

Chemical agents have been added to the welding wire used during welding. After the welding wire melts, it can protect the weld and prevent oxidation.

Flux-cored wire welding has the advantages of fast welding speed and high shift duty, and is suitable for some occasions

In short, welding methods without gas protection have been widely used in various occasions. For some confined spaces and slightly complex welding tasks, this welding method is more suitable.

FAQ

What’s the easiest welding to learn

Factory work, go to work on the construction site

The most common welding methods in factories are argon arc welding, secondary welding, single-sided or double-sided forming, and multiple layers can be used for employment.

What are arc welders used for

As an important welding equipment, arc welding machine plays an irreplaceable role in modern industry. It realizes the needs of repair, manufacturing and construction by melting metals and joining materials. At the same time, arc welding machine also adapts to the development trend of automation and robotics, improving production efficiency and welding quality.

What is a welding machine called

Laser welding machine is also called laser welding machine, and also has names such as laser cold welding machine, laser argon welding machine, laser welding machine, laser welding machine, etc.