With the rapid development of science and technology, laser ablation rust removal has emerged in the rust removal market and has become a new type of equipment for removing rust and oxides. This article will tell you about laser ablation rust.

What is laser ablation rust removal

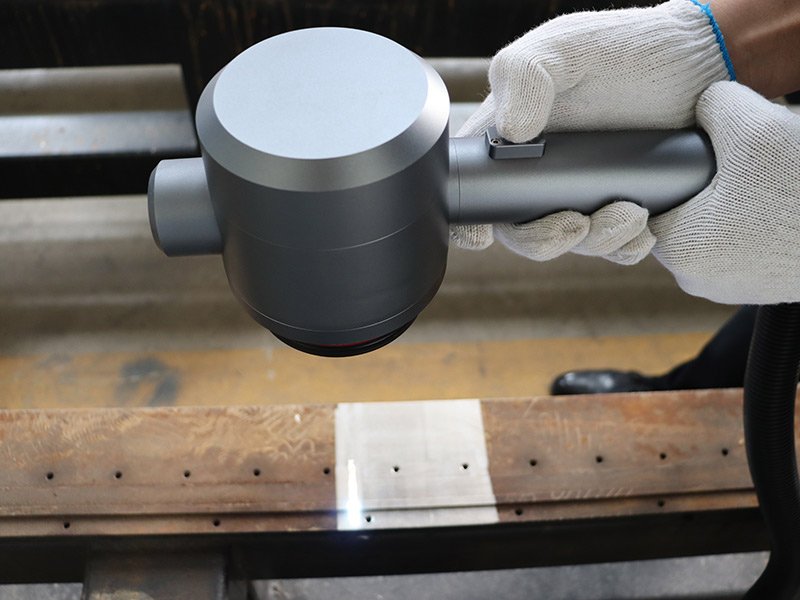

Laser ablation is a technology that uses laser to remove oil, rust, oxides, paint, and layers on metal surfaces.

It has the advantages of good directionality, high brightness, and good monochromaticity, and is widely used in various fields.

Principle of Laser rust removal

Using the high energy, high density, and high focus of the laser beam, the impurities and oxides on the metal surface are heated and evaporated to separate them from the metal surface, thereby achieving cleaning of the metal surface.

Laser rust removal type

Continuous Laser Beam vs. Pulse Laser Beam

Pulsed lasers are generally better suited for ablation processes and have higher peak powers. The simple operation process can effectively avoid damaging parts.

Continuous wave lasers can ablate and remove material when the laser intensity is high enough.

When welding overlaps, if there are some shallow welds, pulse laser can be used;

Relatively deep welds require the use of continuous wave lasers

Laser rust removal tool features:

- The laser focusing spot is adjustable and suitable for micro-scale processing;

- Non-contact processing, not affected by material hardness and reducing secondary pollution during processing;

- The materials have strong compatibility, and only one step of processing is needed to induce phase change processes in materials such as metals, semiconductors, glass and polymers, ultimately achieving material etching, welding, drilling, cutting, surface condensation, cladding, alloying and Impact hardening and other processing processes.

Laser ablation technology is one of the important research directions in the field of preparing functional micro-nano structures.

Application of laser ablation in semiconductor

The electronics industry is developing rapidly, and semiconductors can be seen everywhere around us. During assembly, tiny components stick to the end face of the suction nozzle. Laser ablation machines can solve this problem.

How much does a Laser Ablation Rust Removal cost?

Laser Ablation Rust Removal equipment, depending on the plate to be cleaned and rust removed, the required power, laser, continuous or mopa pulse, configuration, etc., have an impact on the price. Generally, the power size is 100w 200w 500w 1000w 1500w 2000w 3000w. The price is different from 6,000 US dollars to 100,000 US dollars, and the price of high-power laser rust removal machines is higher and relatively more expensive. For specific prices, you can consult the manufacturer and supplier.