Laser cutting is the darling of the industrial market due to its high cutting accuracy and fast speed. It has been widely used in aerospace, ship manufacturing, steel structures and other fields. If you want the laser cutting machine to obtain the best cutting effect, use material settings Very important, this article will take you through the laser cutting settings of different materials.

Different laser cutting machines can cut different materials, metal, wood, glass, acrylic, leather, foam, etc.

Set Laser Cutter Settings for Different Materials

Wood:

Wood is one of the most commonly used materials in laser cutting. The key to successful wood cutting lies in controlling the laser power, speed, and focus. Here are some general settings to consider:

- Power: 60-80% (varies based on wood type)

- Speed: 100-300 mm/s

- Focus: 2-3 mm above the material

Acrylic:

Acrylic is another popular material for laser cutting, and it requires a different approach. To prevent charring and achieve a smooth finish, consider the following settings:

- Power: 20-80%

- Speed: 20-150 mm/s

- Focus: 0.5-1 mm above the material

Leather:

When cutting leather, it’s important to maintain precision and avoid excessive burning. Try these settings:

- Power: 40-60%

- Speed: 50-100 mm/s

- Focus: 1-2 mm above the material

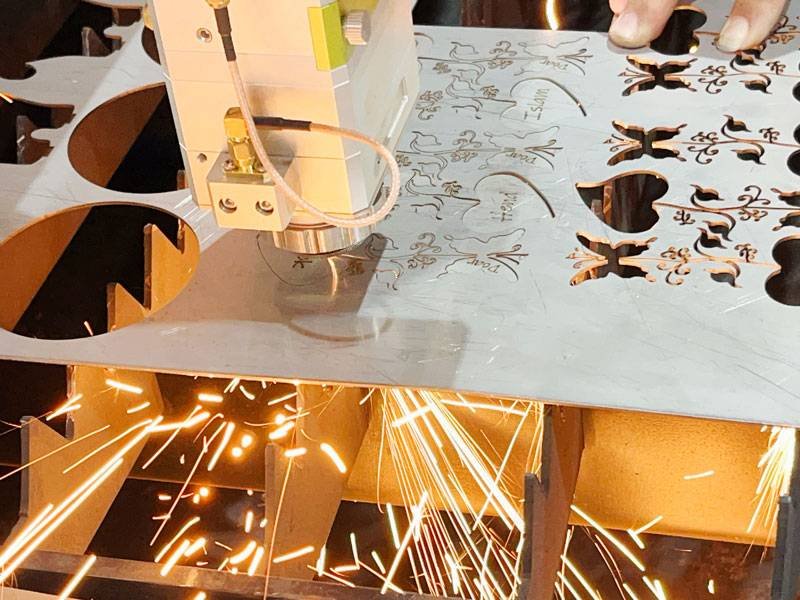

Metal:

Laser cutting metal is a complex process that often requires a higher-power laser. Settings can vary greatly depending on the type and thickness of the metal, but here are some general guidelines:

- Power: 80-100%

- Speed: 0.1-2 mm/s

- Focus: 0.1-2 mm above the material

Paper:

Paper is a delicate material, and the settings must be adjusted to avoid burning or tearing. Use the following settings as a starting point:

- Power: 10-30%

- Speed: 200-400 mm/s

- Focus: 0.5-1 mm above the material

Fabric:

Laser cutting fabric offers precise, clean cuts. To ensure the best results, try these settings:

- Power: 30-50%

- Speed: 50-150 mm/s

- Focus: 1-2 mm above the material

Foam:

Foam materials, like EVA or foam core, are popular for crafting and prototyping. Here are some recommended settings:

- Power: 30-50%

- Speed: 50-150 mm/s

- Focus: 1-2 mm above the material

Is laser engraving settings the same as laser cutting?

Different, laser engraving settings for different materials are also designed differently. Laser engraving only produces logos, text, graphics, etc. on the metal surface. Cutting machines and engraving machines have great differences in power consumption, speed and PPI. For large differences, you can refer to the laser cutting equipment user manual to determine the correct cutting and engraving settings.

Is it dangerous to use incorrect laser cutter settings?

There is danger. The laser will produce high-energy heat and has strong penetrating power. If the laser cutter settings are incorrect, it will cause many dangers. Therefore, you need to pay attention to protective measures. Do a good job before starting the machine and do a good job when shutting down to ensure safety.