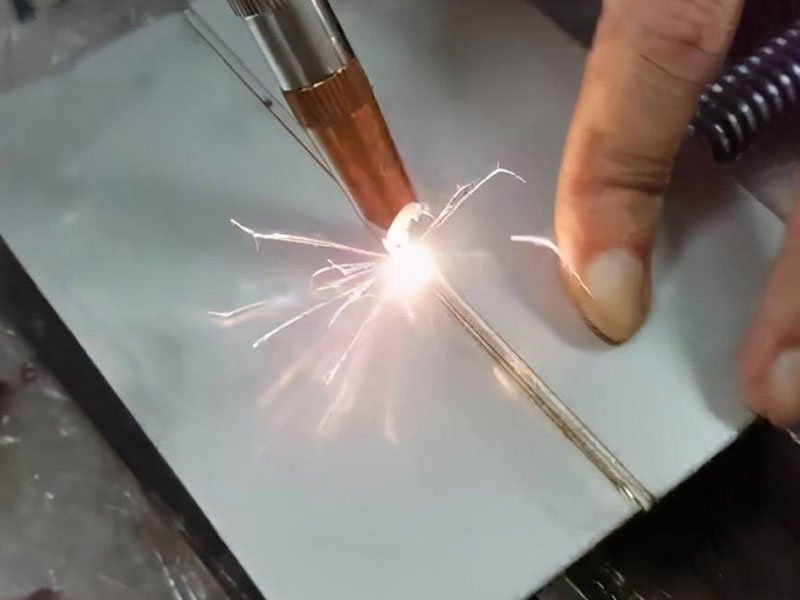

With the rapid development of the industrial market, handheld laser welding machines have gradually replaced the traditional argon arc welding and secondary welding processes, and more and more enterprises are using laser welding equipment, automotive manufacturing, industrial electronics, aerospace, shipbuilding, jewelry, etc.It can be said that laser welding finds widest application in.

Types of laser welding machines

Laser welding machines are based on different welding machines, handheld welding machines, etc.

Welding methods: laser brazing machine, laser fusion welding machine, laser filler wire welding machine, laser welding robot, etc.

Power size: micro-power laser welding machine, small and medium-power laser welding machine, high-power laser welding machine, etc.

Laser type: waveguide laser welding machine, fiber laser welding machine, semiconductor laser welding machine, etc.

Different types of laser welding machines have different characteristics and application ranges. Only by selecting a suitable laser welding machine according to specific applications and requirements can we achieve better welding effects and improve production efficiency.

Advantages of laser welding

- The laser welding machine has large output energy and fast welding speed;

- The laser welding machine has high accuracy and strong adaptability, and can perform giant and micro welding;

- Laser welding machines can be used in mass production, saving manpower and material resources.

Related articles

Laser welding application

- Machinery manufacturing

The machinery manufacturing industry not only has huge equipment, but also has arduous welding difficulties, and there are safety hazards in the welding process. Laser welding machines can avoid manual contact and automate the entire process, making them a veritable “welder” in the machinery manufacturing industry and very popular.

- Laser welding applications in automotive industry

As cars are commonly used means of transportation, the public also has higher requirements for the appearance after welding. The use of laser welding machines can achieve fast welding, full welds, strong welding, easy cleaning, and is more in line with the production requirements of high-end products.

- Electronic equipment

Electronic equipment is an indispensable tool for modern life, work, and study. Its welding difficulty lies in its small size but high requirements. Laser welding can break the space restrictions, and the welding angle can be changed at will to ensure the welding quality.

- Jewelry industry

Jewelry is precious and delicate. The laser welding machine uses a microscope to enlarge the small parts of the jewelry to achieve precision welding without deformation after repair. It solves the two major problems of weld beauty and welding quality, making it an indispensable welding equipment.

- Aerospace

In aerospace, there are many components and parts involved in the airframe, so the welding requirements are also very high. Laser welding can not only flexibly set parameters, but also achieve precise welding, especially for equipment and facilities with complex structures.

Laser welding examples

Aluminum and aluminum alloys, copper and copper materials, magnesium alloys and titanium alloys, among which aluminum alloys and their aluminum-copper joints are the most common laser welding materials.

If you are interested in our laser welding machines, you can consult us for laser welding pdf and techniques.