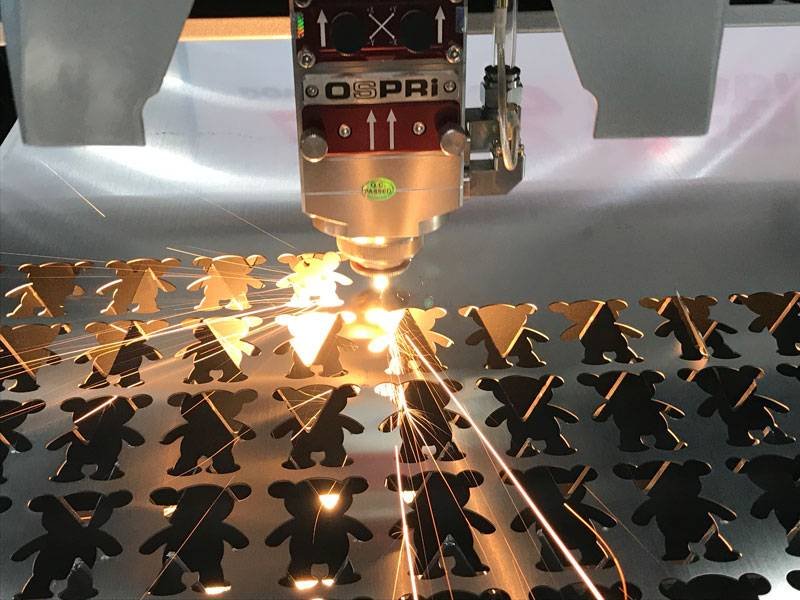

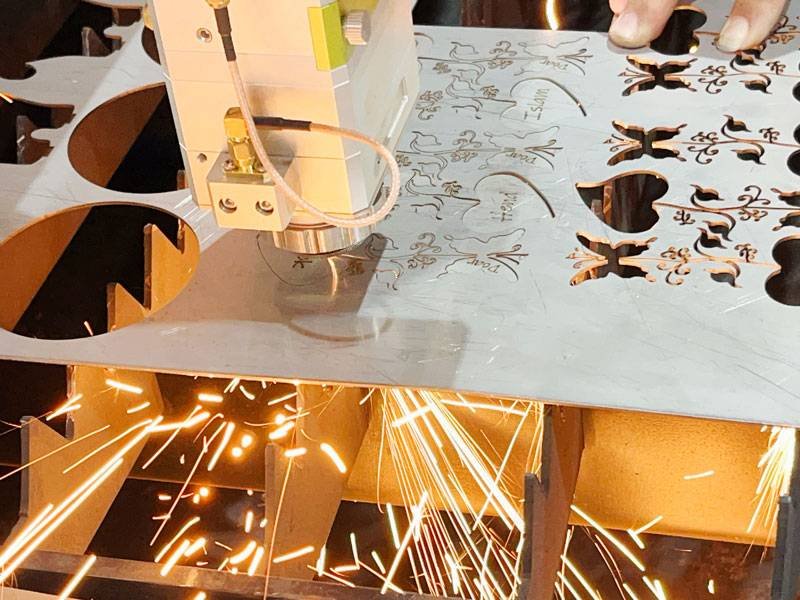

With the rapid development of science and technology, the CNC equipment industrial market because of saving time to improve work efficiency, favored by business owners, but at the same time, Fiber Laser Cutting Machine Accident also occur from time to time, CNC machine accidents death happens a lot,, because of old laser cutting machine used for a long time, the technician is not properly operated, and other factors caused by accidents.

To avoid the occurrence of such a sad thing cnc machine accident death from happening again and protect everyone’s life safety. this side of the article around CNC machining accidents, fiber laser cutting machine incidents, laser safety hazards, and how to avoid accidents in production. In addition to reminding the operator of the use of fiber laser cutting equipment need to pay attention to good safety measures.

Laser Cutter Safety Incident

July 12, 2018 Boston 25 News reports that a metal worker at the salon was trapped in a laser cutting equipment containing sheet metal for more than an hour and died after being taken to the hospital.

The Laser Cutter Accident Investigation that led to the man’s entrapment remains under investigation, officials said.

February 23, 2023 (KSNB/Gray News) A Nebraska worker died Monday morning after becoming trapped in a laser cutter at work.

According to Kearney Police Lt. Derek Luke, emergency personnel responded to a report of a man trapped in laser cutting equipment around 5:45 a.m. When officers arrived, the worker Already died from his injuries.

Most of the Fiber Laser Cutter Incident Reports point out that the causes of the tragedy include both human and non-human factors.

Is fiber laser safety

Laser cutting equipment issued by the laser as a special energy light source, to a certain extent there is radiation. The laser emitted by the laser because of its monochromaticity, coherence, collimation and high energy density and easier to achieve the effect of energy concentration, and therefore harmful to human organs (especially the human eye).

Fiber laser cutting machine accident video

What are the hazards of laser radiation side effects?

- First level: under normal operation, it will not emit light radiation that is harmful to human body.

- Level 2: Its radiation range in the visible spectral region, this level of products need to be attached to the warning symbol for safety inspection.

- Level 3: When viewed directly with the naked eye or with a lenticular instrument, it can lead to unintentional harm.

- Level 4: Hazards not only to the human eye when viewed directly, but also to the skin under other conditions, and even to the human body if a fire is started.

Fiber laser cutter operators will have some side effects when using equipment, so it is necessary to do a good job of safety protection.

What are the basic hazards of laser equipment?

For lasers in the infrared spectral region, the hazards to the human body are mainly thermal effects, and for lasers in the blue and violet spectral regions, the hazards are mainly photochemical effects. Therefore, when the human eye is accidentally directly confronted with a laser emitted from a laser or fiber optic connector, it may cause eye damage. In the case of ultraviolet lasers, this can lead to corneal inflammation and cataracts.

Causes of fiber laser cutting machine accident:

- Cutting sparks sting the eyes.

- Non-professionals open the laser right shell, resulting in an electric shock accident.

- Safety protection, operation, and control devices, such as failure, loss of control triggered by the accident; 4, improper maintenance of electrical components in disrepair, aging, line damage, insulation, grounding bad trigger accident; 5, non-equipment operators to operate the machine.

- Non-equipment operators operate the equipment, unauthorized operation, improper command, poor coordination, and misoperation caused by accidents.

- Not by the provisions of the wear labor protective equipment and other accidents caused by.

- The operation process is not coordinated, the workpiece items are placed, and stacking does not meet the safety requirements caused by accidents.

Preventing fiber CNC machine accident death

The power supply of industrial lasers ranges from several thousand volts to tens of thousands of volts, which can be fatal. High voltage and X-rays generated by electron tubes under high voltage can cause harm. Special attention should be paid to the danger

Before performing any maintenance, all power supplies should be disconnected to ensure that high voltage has been discharged from the capacitors. Failure to do so may result in severe electric shock or even death.

The following safety precautions should always be observed

- Do not work in high-pressure areas alone or

- Do not work in high-voltage areas if your body is sweating (the resistance of a wet body will be greatly reduced);

- Remove all metal jewelry (watches, rings, necklaces) and other metal items (such as belt buckles).

Fireproof

When using the laser cutting machine, be careful not to pile any debris on the laser. Also, beware of fire:

Ensuring Laser Cutting Machine Safety Operators must not place flammable materials where the laser beam may be illuminated. If the laser beam illuminates flammable materials, it will cause a fire.

Accident prevention for machine tools and accessories

- Do not touch any switch with wet hands to avoid electric shock. Parts of machine tools with lightning signs indicate that these parts contain high-voltage electrical appliances or electrical components. Operators should be particularly careful when approaching these parts or opening them for maintenance to avoid electric shock. Such as a protective cover for the servo motor position, junction box behind a column, machine tool transformer cabinet, electrical cabinet door, etc.;

- Read the machine tool manual and electrical schematic diagram comprehensively and carefully to familiarize yourself with the operation methods of various functions and corresponding keys;

- Do not open the electrical cabinet door easily, and it is prohibited to change the set machine parameters, potentiometers and timers without permission. If changes are required, they must be operated by professionals trained and approved by the equipment manufacturer, and the parameter values before the change must be recorded so that the original state can be restored if necessary;

- Do not touch live components in the electrical cabinet when the power is on, such as CNC devices, servo devices, transformers, fans, etc.

Gas explosion hazard

When cutting certain workpieces, nitrogen is often used as an auxiliary gas. In an occluded space, excess nitrogen may cause hypoxia. An aging trachea may burst or be punctured by a sharp instrument, so please pay attention to safety!

Excess oxygen may cause fire when using oxygen as an auxiliary gas. It is strictly prohibited to pile up flammable and explosive items around the machine tool! A fire extinguisher should be installed near the machine.

When shutting down, make sure:

- Turn off the compressed air compressor and lock the stop valve;

- Close the stop valve;

- After turning off the gas supply, wait a few seconds until the gas disappears;

- Check that the operating pressure has dropped to 0 bar. Check the pressure gauge panel for current operating pressure.

Gas toxicity hazard

Optical devices

Optical devices such as focusing mirrors are manufactured using the chemical vapor deposition (CVO) method, mostly ZnSe. When the ignition point is exceeded, toxic Se vapor is generated, which is a highly toxic substance.

To increase the transmittance, the lens is coated with a compound film of the reflective substance thorium. When the lens is damaged, it should be properly disposed of per the relevant regulations of all countries and cannot be disposed of as regular waste.

Target

Target gasification and reaction products during laser processing, such as metal vapor (or spatter), etc., may not only cause air pollution but also easily cause flammable materials (cloth, oil, etc.) around the work area to burn and cause fires.

Laser cutter safety precautions, requirements

- The laser has adverse effects on the human body, in the operation process to protect the weak parts of the body, such as eyes, exposed skin, etc., one should not use the eyes to look directly at the laser in the cutting.

- During the operation process, any part of the human body can not be within the running track of the beam to avoid being touched.

- In the operation process, one can not open the laser, the body, the chiller circuit control cabinet, to prevent high-voltage electrical hazards to the human body.

- Laser cutting machine in the maintenance must be turned off before the power supply, is repaired before the power check.

- Gas cylinders can not be stacked near the point of any flammable material, there can be no source of ignition.

Related articles

- Laser Cutter Safety Comprehensive Standards Guidelines

- How To Operate Laser Cutting Machine

- How Does A Laser Cutter Work

How to Respond to a Laser Cutter Injury

- Prepare necessary laser cutting machine protective equipment before operating the equipment, and wear laser protective glasses.

- Operators should pay attention to eating more foods rich in vitamin AC and protein such as carrots, bean sprouts, tomatoes, lean meat, animal liver, etc. to protect their eyes.

- Corresponding dust removal devices should be equipped, and operations should be carried out in an environment with unobstructed air and wearing masks.

- Do not touch the cut parts immediately after processing to avoid burns due to residual heat.

- Since the laser beam is an invisible beam, do not touch the light path during use to avoid damage to the body.

- There are harmful elements (ZnSe) in the focusing lens of the laser cutting machine. Do not touch the lens frequently. The lens must be specially processed after it is scrapped. Do not throw it around.

Safety Protocols for Laser Cutting Machines

Laser Machine Operators need to sign a safety agreement with the company and purchase insurance before taking up their jobs, which can give the operator a safe guarantee to prevent accidents.

The above is the information about Fiber Laser Cutting Machine Accidents, hoping to help you improve the safety of your laser cutting work.