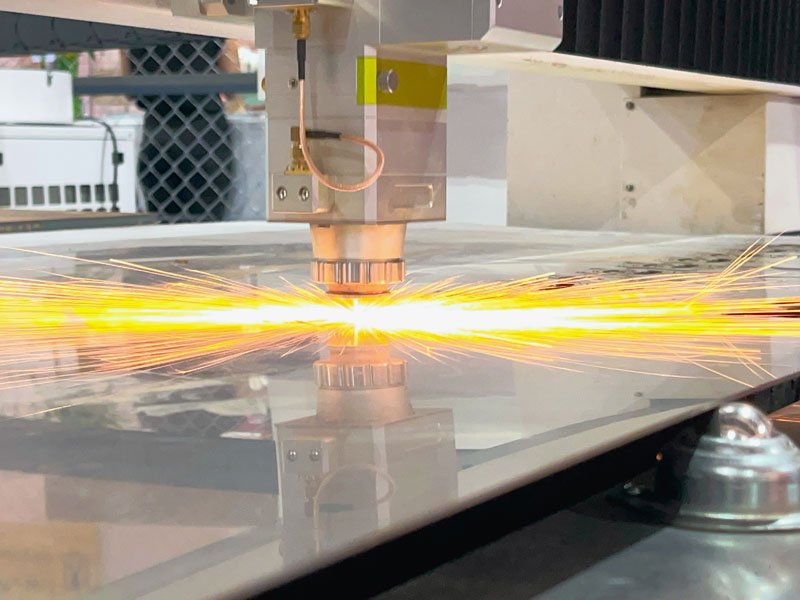

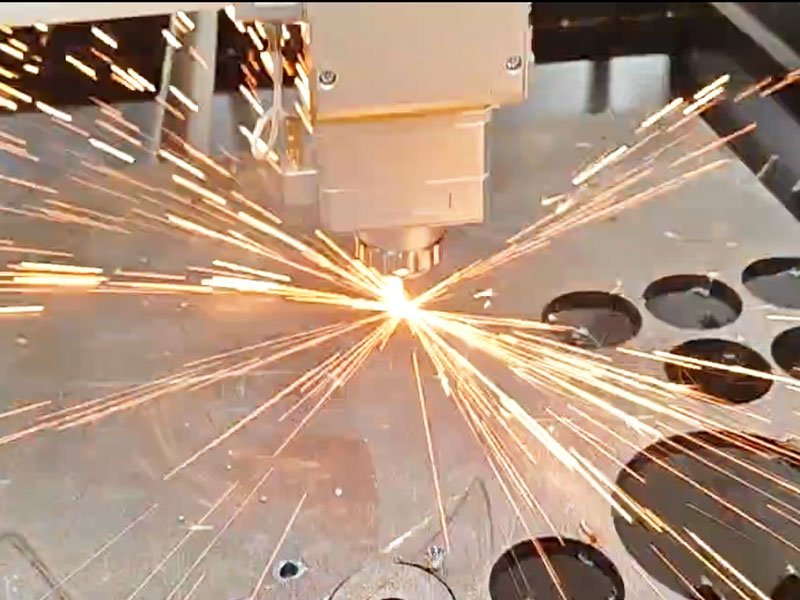

Many purchases of metal laser cutting equipment for newcomers to the industry, will encounter a number of cutting problems, laser cutting parameters should be how to adjust the following solutions:

With the rapid rise of the laser cutting market, understanding fiber laser cutting parameters can allow us to better choose the right equipment.

The power of the laser cutting machine has also evolved from the original 500w 1000w 1500w 2000w, and the low power has gradually moved towards the development of higher power 4000w 6000w 8000w 12kw 15kw 20kw 30kw. If the fiber laser cutting parameters are set incorrectly, great losses will occur. The following is Let’s take a look at the parameters of different powers.

8 Affect fiber laser cutting parameters

Cutting height, nozzle type, focus position, cutting power, cutting frequency, cutting duty cycle, cutting air pressure and cutting speed.

Feed rate:

The continuous cutting time is inversely proportional to the moving speed of the cutting head on the material plane. The higher the speed, the shorter the duration and vice versa.

Some geometric parameters also have an effect on speed. When the time is similar, the spacing between cutting parts is too small, which will cause heat accumulation in the material and affect the cutting speed.

Cutting head height:

The laser beam is focused below the nozzle through the lens, and the power density at the focus is maximum. The height of the cutting head from the cutting surface not only affects the plane focusing area, but also affects the energy density at the current point.

Basic photocurrent:

Determines the power of the laser beam. At a ratio of 100%, the laser beam reaches maximum power.

Laser pulse frequency:

In addition to continuous laser beams, pulsed laser beams are also used, laser beams that are turned on and off continuously and rapidly. Adjust the duty cycle to adjust the power to achieve special functions.

Laser pulse duty cycle:

The percentage of time a pulsed laser is on during a cycle is directly proportional to the laser power. When the duty cycle is 100%, that is, it is fully turned on in one cycle. This is a continuous laser.

Laser power supply:

The laser power supply is divided into several parts to provide energy. Some components are individually switched off to reduce laser power.

Laser power modulation:

In order to match different cutting speeds, special equipment is used to adjust the laser power at any time.

Auxiliary gas:

Protect the cutting head from smoke and dust and improve cutting quality.

Hardware conditions are: protective lenses, gas purity, plate quality, aggregation mirror and collimation mirror.

When the cutting quality is poor, the main inspection content and order.

- Cutting height (the actual cutting height is recommended to be between 0.8~1.2mm), if the actual cutting height is not allowed, calibration is required.

- Cutting nozzle check whether the type and size of cutting nozzle is used wrong, if it is correct check whether the cutting nozzle is damaged and whether the roundness is normal.

- Light center is recommended to use 1.0 diameter nozzle for light center check, and the focus is best between -1~1 when checking the light center. This way the light point is small and easy to observe.

- Protective lens Check whether the protective lens is clean, requiring no water, no oil, no slag point. Sometimes the weather or pavement gas is too cold and other reasons cause the protective lens fogging.

- Focus check whether the focus is set correctly. If it is an auto-focus cutting head must use the cell phone APP to check whether the focus is correct.

- modify the cutting parameters

After the above five items are checked and are no problems, and then according to the phenomenon of targeted modification parameters.

Cutting stainless steel and carbon steel will encounter the state and the solution

- Stainless steel hanging slag, hanging slag type has a variety.

If only corner hanging slag can first consider corner rounding, parameters can reduce the focus, add atmospheric pressure, etc..

If the whole hanging hard slag, need to reduce the focus, add atmospheric pressure, increase the cutting nozzle, but the focus is too low or air pressure will lead to cross-sectional delamination and surface roughness. If the overall hanging granular soft slag, you can appropriately increase the cutting speed or reduce the cutting power. - When cutting stainless steel, the cutting side of the end of the slag, you can check whether the gas supply is not enough gas flow to keep up.

- Cutting carbon steel when the thin plate section is not bright enough, thick plate section roughness and other problems.

Generally speaking, 1000W laser can cut no more than 4mm carbon steel bright, 2000W is 6mm, 3000W is 8mm.

Want to cut the section bright first of all, the plate must be good surface rust-free paint-free oxide, followed by high oxygen purity of at least 99.5% or more, in the cutting need to pay attention to: a small cutting nozzle double layer 1.0 or 1.2, cutting speed needs to be fast more than 2m / min, cutting air pressure should not be too large.

Want to thick plate cutting section quality, first of all, to ensure that the plate and gas purity followed by the choice of cutting nozzle, the larger the aperture section quality will be better, but at the same time the section taper will be greater.

Important parameters for setting the fiber laser cutting machine:

Laser cutting requires the setting of various parameters. Different parameters will affect the quality and efficiency of cutting. The parameters that affect laser cutting are: power, cutting speed, power, gas, air pressure, type and size of the laser head nozzle.

Laser power:

The laser is an important energy output system, which represents the thickness of the cutting material that can be melted per unit time. The higher the power, the thicker the plate will be cut. The laser power is the average output power. Different materials require different power levels.

3kW can cut stainless steel to 12mm, and 1kW can cut stainless steel to 5mm. You need to check other parameter settings, focus, air pressure, and cutting speed to ensure the best cutting effect.

Cutting speed:

The linear length of word material that can be cut per unit time. The faster the speed, the shorter the cutting time and the higher the efficiency. It is not good to cut too fast or too slow. The cutting speed must be properly balanced with parameters such as power and air pressure.

Related articles

- Interpreting The Fiber Laser Cutting Speed Chart And Thickness Chart

- Laser Cutting Speed And Power Chart : 6kw Vs 12kw Laser Cutter

Focus:

The energy output by the laser is eventually concentrated on the focal point. The focal spot diameter is proportional to the focal depth of the focusing lens. Correctly setting the focus position ensures cutting quality.

Nozzle distance, location, size:

The distance between the nozzle and the cutting material is related to the air pressure and flow rate. Generally, the appropriate distance is between 0.8-1mm. If it is too far, the air pressure will be lost and splashing will occur.

The size of the nozzle selected for different cutting materials is different. The thicker the metal, the larger the nozzle.

Nozzle type: single layer and double layer.

The single-layer nozzle uses nitrogen as the auxiliary gas and is usually used for cutting stainless steel, aluminum alloy, brass, etc.;

the double-layer nozzle generally uses oxygen as the auxiliary gas and is usually used for cutting carbon steel.

Before use, consult the laser cutting machine supplier to find out what kind of nozzle is required for cutting.

Before cutting anything, you need to center the nozzle, if it is not centered, it will affect the cutting effect.

Auxiliary gas and pressure:

The auxiliary gas treatment function is to burn the textile material, cool it, and blow out the slag. Common auxiliary gases include oxygen, nitrogen, inert gas and air, and the required gas purity is 95.5% or higher.

Most metals use oxygen, and some special metal and non-metal cutting uses inert gas or compressed air.

The pressure of the gas can help increase the cutting speed. If the material thickness increases or the cutting speed is slow, the gas pressure should be appropriately reduced. Cut with lower air pressure to prevent frost formation.

Material material, thickness:

When determining how to set cutting parameters, material type, thickness, reflectivity and thermal conductivity also need to be considered. Thicker sheets will reduce cutting quality. Metals with high reflectivity (also known as non-ferrous metals) require more power to cut than other metals, and the materials themselves have coatings and spray paint that can also affect cutting.

Some special materials take a long time to melt and cut, and need to be preheated in advance.

Focusing lens condition:

The lens must be good and free of contamination. Damaged or dirty lenses will affect cutting quality or reduce cutting performance.

Cutting path:

Complex paths will reduce the cutting speed, and the laser control is also higher, with the slowest speed at sharp corners.

3kw Fiber laser cutting machine parameters for 12mm carbon steel

Focal lens: 125mm

Spot diameter: about 0.2-0.25mm

Cutting speed: 1-1.5 meters/minute

Oxygen spray volume: 1-1.5L/minute

Point spacing: about 0.2-0.5mm

Spot position: Located above the surface of the workpiece, the distance is about 0.8-1.2mm

If you want to know more about 1000w 1500w 2000w 3kw 4kw 6kw cypcut ipg raycus fiber laser cutting parameters stainless steel you can consult us to get the relevant laser cutting parameters pdf.