The rapid development of industrial laser cutting equipment has led to the emergence of different types of laser cutting machines. It is troublesome for customers to choose the appropriate type. This article will describe the types of laser cutter and hope it will be helpful to you.

How Many Types of Laser Cutting Machine

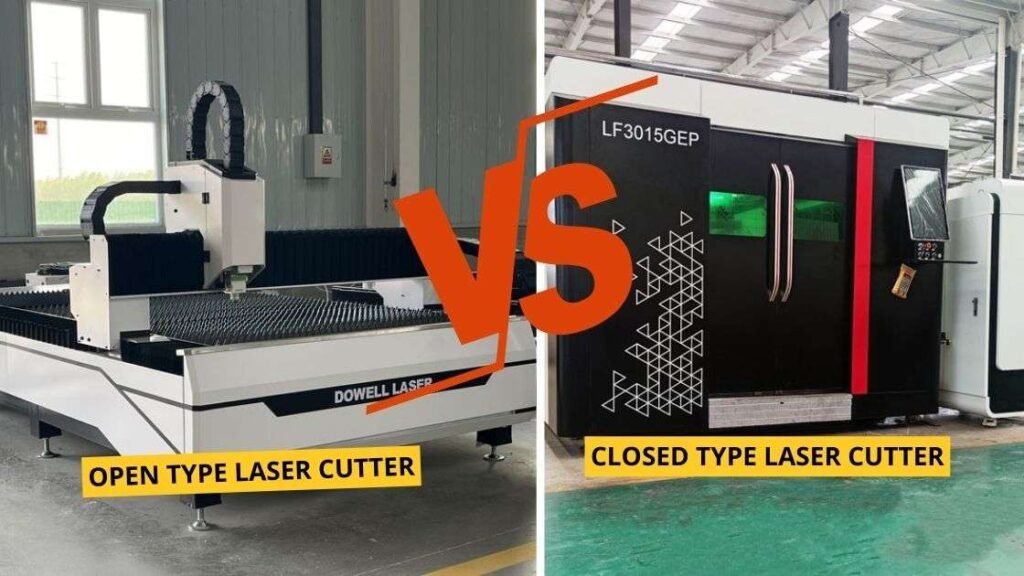

hoosing the right laser cutting tool depends largely on your project needs. There are two main types on the market: open and closed. While both utilize lasers for precise material cutting, there are significant differences in their design and functionality.

Different Types of Laser Cutting Machine

Shell:

Open type laser cutting machine: An open machine has no housing around the cutting area. This provides unobstructed views and simplifies the loading/unloading of large or bulky materials.

Enclosed type laser cutting machine : Features a fully enclosed chamber to accommodate the cutting process. This design provides better safety and smoke control.

Safety:

Open type laser cutting machine : Exposed laser beams in open machines require stricter safety protocols. Operators must wear protective eyewear and follow safety guidelines to avoid accidental exposure.

Enclose type laser cutting machine : An enclosed chamber in an enclosed machine essentially minimizes the risk of laser beam exposure, making it a safer option, especially for beginners.

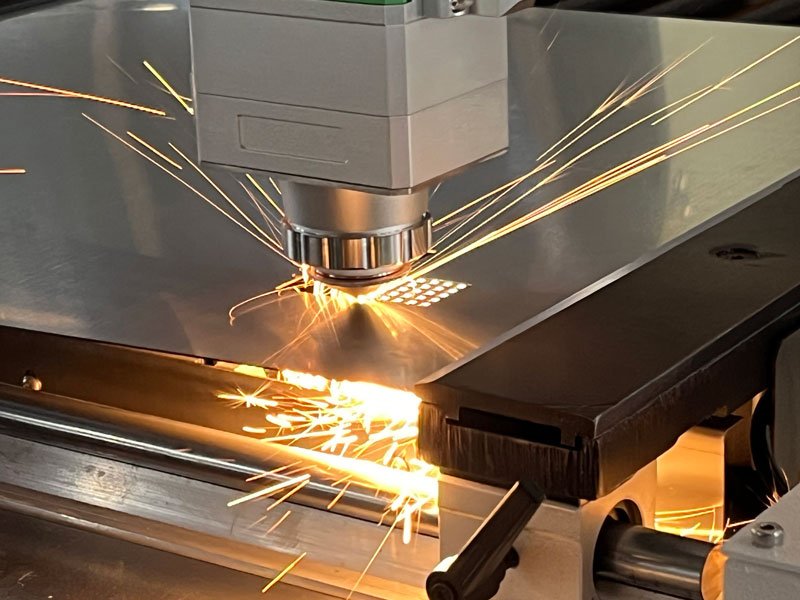

Air quality:

Open: Laser cutting generates smoke and dust. Open machines require a robust ventilation system to remove these contaminants and ensure a safe working environment.

Enclosed: Enclosed chambers in enclosed machines help suppress smoke and dust. They are usually equipped with built-in filtration systems to simplify air quality management.

Noise:

Open design: Open design allows for greater noise during operation. Hearing protection is essential for operators who use open machines for extended periods of time.

Enclosed: An enclosed room in a closed machine helps to reduce noise levels and create a quieter working environment.

Cost:

Open-ended machines are usually cheaper due to their simpler design.

Enclosed: Additional features such as enclosures and filtration systems result in higher prices for enclosed machines.

Application:

Open plan: Ideal for large projects involving large sheet metal due to its ease of loading and generally large work area. They are commonly used in industries such as construction and shipbuilding.

Enclosed: Ideal for applications that prioritize safety, air quality, and noise control. They are popular in workshops, manufacturing floors, and environments with stricter safety regulations.

Design of Open Type and Closed Type Laser Cutting Machines

Accessibility:

The open design of open type machines allows for easier loading and unloading of large or bulky workpieces.

The enclosed design of closed type machines restricts direct access to the cutting area.

Work Area Size:

Open type machines typically have a larger work area to accommodate bigger metal sheets, plates, and 3D parts.

Closed type machines generally have a more limited work area size.

Safety and Environmental Control:

The enclosed design of closed type machines better contains laser radiation, fumes, and debris, improving safety and environmental control.

Open type machines have less containment, requiring more safety precautions.

Precision:

The enclosed design of closed type machines is less susceptible to vibrations, potentially providing higher cutting precision.

The open frame of open type machines may make them more prone to vibrations that can impact cutting accuracy.

The key differences in design are the presence or absence of an enclosed cutting chamber, which impacts accessibility, work area size, safety, environmental control, and cutting precision between the two types of laser cutting machines.

Choose the Right Types of CNC Laser Cutting Machine:

- Consider project needs: If your project involves large, bulky materials and affordability is a priority, an open-frame machine may be suitable.

- Safety first: If safety and air quality are critical, or you’re a beginner, enclosed machines provide a safer, more controlled environment.

- Consider noise levels: If noise reduction is important for your workspace, an enclosed machine may be a better choice.

The best choice depends on your specific requirements and priorities. By understanding the key differences between open and enclosed laser cutters, you can make an informed decision for your project.