In the field of fiber laser cutting machines, cutting accuracy is a topic of concern. For the buyer of a laser cutting machine, understanding the subtle differences between bevel and bevel cutting is essential to achieve optimum accuracy and efficiency. This article will be tailored for laser cutting machine buyers to provide an in-depth introduction to the differences, applications, advantages and considerations of Bevel vs Miter Cut.

What is a bevel cut definition in laser cutter

Bevel cutting refers to the process of cutting materials into bevels at a certain angle, thereby changing their shape and structure. Bevel cutting can be used for cutting different materials, precise control of the cutting angle, and smoothness requirements of the cutting surface.

During the cutting process, the cutting surface and the material plane should have a cutting intersection angle lower than 90°, which can facilitate the welding between materials and increase the firmness of the welding.

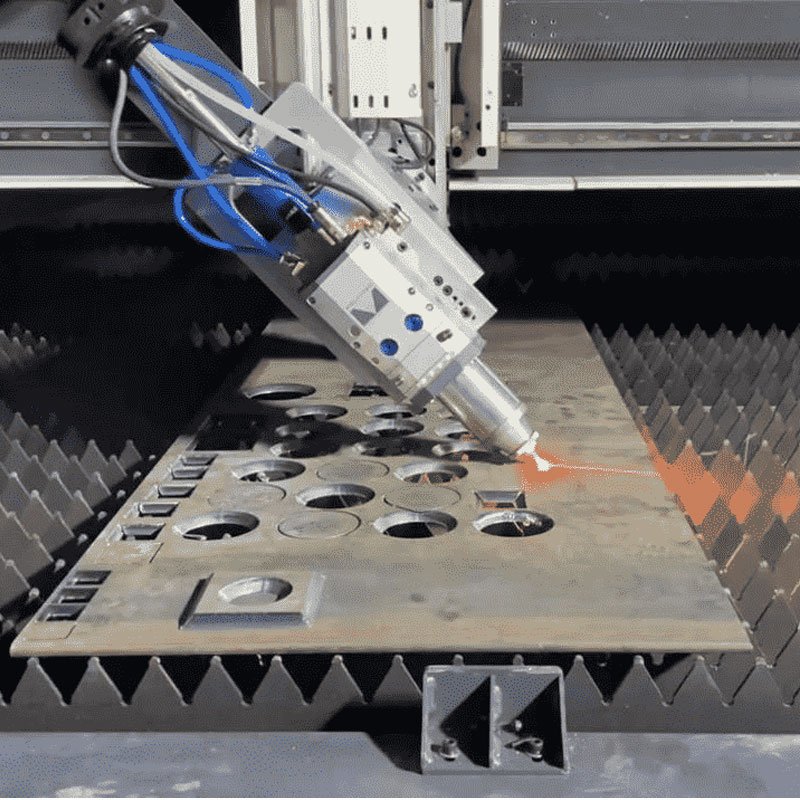

What Is A Bevel Cut In Fiber Laser Cutting Machine

What is a miter cut definition

Miter cuts are performed by rotating the saw blade or workpiece relative to the material surface. Cutting is usually made across the width of the material. Use to create seamless corner joints or achieve a clean polished look.

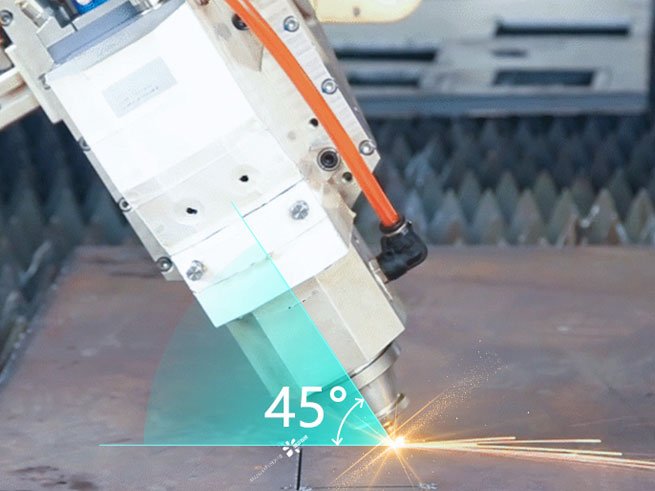

The miter cut angle is also less than 90 °. The miter cut is 45 °

What are bevel cuts used for

In bridge steel structures, shipbuilding, engineering machinery and other industries, the use of thick steel plates is indispensable. In order to ensure the strength of the welding, the connection between the steel plates requires groove processing, which has high requirements for the groove section. , high precision, no slag, etc. on the welding surface.

Bevel cut vs miter cut

Miter cuts involve rotating the saw along the x-axis and are suitable for larger baseboards or trim.

Beveling involves laying the saw from left to right, working on the window casing and horizontally.

Bevel cuts are vertical while miter cuts are horizontal.

Cutting Direction:

Beveled through the thickness, while beveled through the width of the material.

Application:

Beveled cuts are suitable for a variety of applications, including joints and angled edges. Miter cuts excel at creating visually appealing corners and are often used for decorative purposes.

Versatility:

Bevel cutting provides versatility in handling different materials and cutting angles. Miter cutting contributes to a precise and aesthetically pleasing finish.

How to use miter saw

Miter saw:

Miter saws are primarily used for cutting large pieces of wood. Miter saws can cut wood at multiple angles, such as house skirtings can be cut at various angles.

- Turn on the blue switch next to the armrest, lift the buckle under the armrest, and move the saw angle according to the scale.

- Turn on the blue switch next to the armrest, pull the front control lever, and adjust the saw blade tilt angle according to the scale.

- After adjusting the angle, push the control lever back and lock the blue switch.

- The angle of the saw edge and the tilt angle of the saw blade can be adjusted at the same time.

How to make long bevel cuts use laser cutting machine

- In order to achieve bevel cutting with a total inclination angle of 31.5°, the high-precision cutting tooling shown in Figure 2 needs to be produced. The dimensional tolerance of the tooling pitch and positioning hole spacing is controlled within ±0.01mm. The shroud is processed in sections and then assembled and welded to solve the problem. The entire circle of diagonal girth exceeds 3000mm. Unprocessable problems.

- Adjust the coupling of laser processing parameters. When the laser power P=1260W, the cutting speed v=1.4m/min, ordinary oxygen (purity 99.8%) is used as the auxiliary gas, and the gas pressure is 0.08MPa, large-angle bevel laser cutting can be achieved. , the slit width is about 0.18mm.

- The distance between the laser head nozzle and the workpiece and the amount of focus have an important impact on the quality of the incision. If the nozzle is too far from the workpiece, the slit will be widened and the roughness will be increased. If the distance is too close, the nozzle will easily collide with the workpiece. The distance is controlled between 0.5~0.8mm from the workpiece, and the surface quality of the cavity after cutting is better. The focus amount (that is, the position of the laser focus inside the workpiece) is about 1mm, which can ensure a smooth cut and no chamfering at the entrance of the cut, thus obtaining good surface processing quality.

- Since it is three-dimensional space closed surface processing, when making the processing program, we must consider not only the accuracy of the surface modeling, but also the linear interpolation step length of the program. Experiments show that the linear interpolation step length is 0.02mm, and the effect is better.

How to determine the focus position of the bevel of laser cutting machine?

There are five methods to determine the focus position in industrial production: dot method, inclined plate method, blue spark method, parallel light tube, and moving lens lower axis. Below we introduce these five methods in detail.

CNC positioning and dotting method:

Move the cutting head from top to bottom, and print the laser beam on the plastic plate. The smallest printing diameter is the focus.

Inclined focus burning method:

Use a plastic plate placed at an angle to the vertical axis to pull it horizontally and find the smallest point of the laser beam as the focus.

Blue spark method:

Remove the nozzle, blow air, hit the pulse laser on the stainless steel plate, and move the cutting head from top to bottom until the maximum blue spark is the focus.

Parallel light tube.

This is a commonly used method, that is, adding a parallel light tube to the output end of the CO2 laser for beam expansion. After the beam expansion, the beam diameter becomes larger and the divergence angle becomes smaller, so that the near and far ends within the cutting working range The beam size is nearly uniform before focusing.

Add an independent lower axis of the moving lens to the cutting head. It and the Z axis that controls the distance (standoff) from the nozzle to the material surface are two independent parts.

FAQ

What is 45 degree miter cut

The 45-degree miter cutting method is a commonly used cutting technique that cuts materials at a 45-degree angle to achieve a more precise cutting effect.

How to cut a beveled edge

If you want to mark the 45mm bevel on the woodworking table saw, you can mark it on the board and then mark it according to the marked line. Use a set square to make a 45-degree bevel on the table saw, then set the board up and start cutting it. Just adjust the table saw to a 45-degree angle.