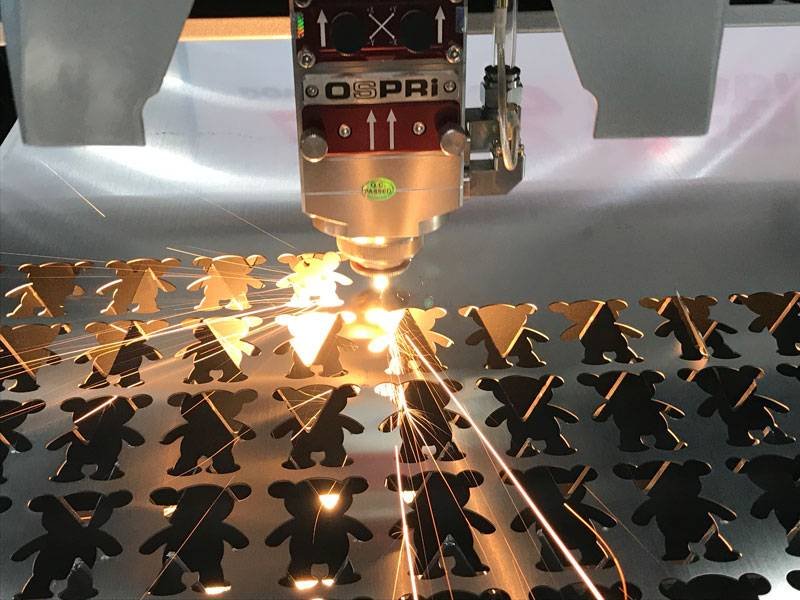

After the epidemic, with the rapid recovery of the industrial market, Laser Cutter for Steel has risen rapidly in the manufacturing field, and many business owners have transformed from the original plasma cutting machine or water jet cutting machine. Because compared with the traditional metal cutting process, laser steel cutter is relatively faster, more efficient and more precise.

Steel plate laser cutting process:

(1) Steel plate blanking:

Cut the steel plate according to the designed drawing

(2) Steel plate marking:

According to the size of the cutting graphics for scribing

(3) Plate positioning:

After securing the panels, make sure the panels are in the correct position

(4) Focusing:

Manual focus to adjust the laser focal length,

(5) Trial cutting:

The workpiece is placed stably, and the cutting treatment test is carried out to see where there is any inappropriate place, and adjust it in time

Laser cutting metal parts

Laser cutter for stainless steel is composed of laser generator, cutting head, beam transmission components, machine table, numerical control system and cooling system and other components.

- Laser generator

A laser generator is a component that produces a laser light source. The heart of the laser cutting machine.

For metal cutting, fiber laser generators are commonly used today. Because laser cutting has very high requirements on laser light source, not all lasers are suitable for cutting process.

- Cutting head

The cutting head is mainly composed of nozzle, focusing lens and focus tracking system.

- Nozzle

Three types: parallel, convergent and cone.

- Focusing lens

The energy of the laser beam is focused to form a high-energy spot.

The medium and long focus lens is suitable for thick plate cutting, and has low requirements on the spacing stability of the tracking system.

The short focus lens is only suitable for thin plate cutting, which requires high spacing stability of the tracking system and lower requirements for laser output power.

- Focus tracking system

The focus tracking system is generally composed of a focus cutting head and a tracking sensor system.

The cutting head includes light guide focusing, water cooling, air blowing and mechanical adjustment.

The sensor is composed of a sensing element and an amplification control part.

Two forms of tracking system

One is a capacitive sensor tracking system, also known as a non-contact tracking system.

The other is an inductive sensor tracking system, also known as a contact tracking system.

- Beam Transmission Components

The core component of the beam delivery assembly is the refractive mirror, which is used to direct the laser light in the desired direction.

The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is introduced to protect the lens from contamination.

- Machine tool table

The machine tool table is mainly composed of a weighing bed and a driving part, which is used to realize the mechanical part of the X, Y, and Z axis movements, and also includes the cutting table.

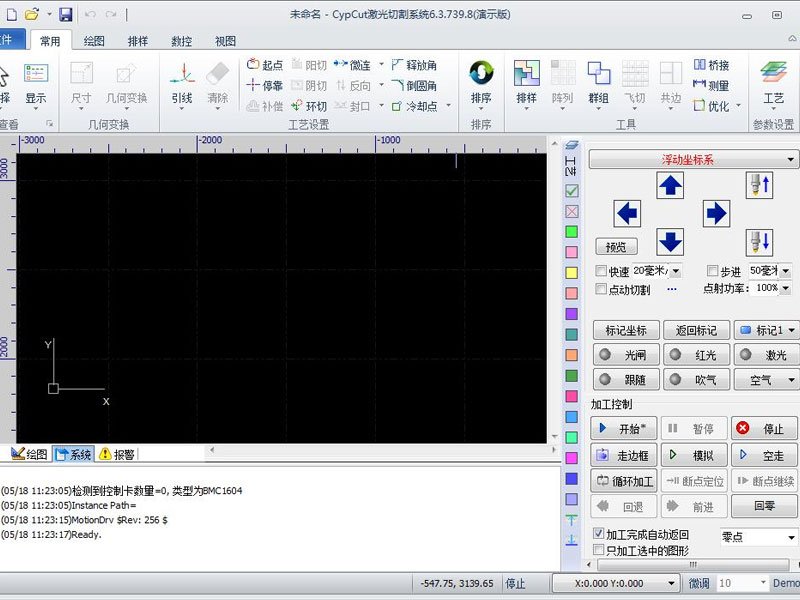

- CNC system

Mainly control the movement of the machine tool to X, Y, Z axes, cutting power, speed and other parameters.

- Cooling system

The cooling system is mainly a chiller for cooling the laser generator.

CO2 laser cutter VS laser steel cutter

Laser steel cutting machine can only cut metal and has great advantages. Carbon dioxide cnc laser steel cutter can cut any material, but the cost of cutting metal is relatively high.

Fiber Lasers:

CO2 laser cutting machine uses carbon dioxide gas laser

Laser cutters use fiber lasers or solid state lasers

Cutting material:

CO2 laser cutters are usually used for non-metal cutting. Cuts materials such as wood, acrylic, plastic, leather, fabric, paper and some types of rubber.

CNC laser cutter for steel cuts metal, stainless steel, carbon steel, aluminum plate, brass, aluminum alloy and other metal plates.

Application fields:

CO2 laser cutters are widely used in signage, woodworking, packaging, textile and other industries.

The stainless steel laser cutter is suitable for steel cutting applications in industries such as automotive, aerospace, construction and metal fabrication.

CO2 Laser Cutting VS Laser Cutting Advantages and Disadvantages

Advantages of CO2 laser cutting:

- Versatility in cutting a variety of non-metallic materials.

- Capable of complex and detailed cuts.

- Can be engraved and marked on some materials.

- Often more affordable compared to laser steel cutting machines.

Advantages of cnc laser cutter for stainless steel:

- High cutting speed, suitable for industrial scale production.

- Excellent cut quality and precision.

- Capable of cutting a wide variety of metal materials including steel, stainless steel, aluminum and copper.

- Thicker metal sheets can be processed compared to CO2 lasers.

- Suitable for flat and 3D cutting applications.

Disadvantages of CO2 laser cutting:

Inefficient when cutting thick metal materials, cutting speed is slower, cannot cut highly reflective materials, and cannot cut steel in large quantities.

Limitations of Laser Steel Cutting Machines:

More expensive than CO2 laser cutters, operator safety could be improved.

In summary, CO2 laser cutting machines are suitable for high-precision cutting of non-metallic materials, while laser steel cutting machines are designed for efficient and precise cutting of metallic materials, especially steel. Choosing between the two depends on the intended application and the material you need to cut.

What laser can cut metal

Laser for cutting metal can cut a variety of metals, from mild steel and stainless steel to non-ferrous metals. Aluminum alloys and other reflective metals are more difficult to cut, at which point fiber laser is a better choice

How thick can a laser cutter cut steel?

| Power | Stainless Steel Thickness Range | Carbon Steel Thickness Range |

| 1000w laser cutter steel | 0-3mm | 0-6mm |

| 1500w laser steel cutter | 0-5mm | 0-10mm |

| 2000w laser metal cutter | 0-8mm | 0-16mm |

| 3000w cnc laser cutter for metal | 0-10mm | 0-20mm |

The power of the laser cutting machine is higher, and the thickness range of the steel plate that can be cut is relatively larger.

The cutting strength of the metal cutting laser machines also needs to take into account the brand, quality, application environment, speed, etc. of the cutting machine. It is not possible to define the thickness of the steel plate that the laser cutting machine can cut according to an absolute standard. It requires multiple considerations and chooses according to the needs. .

FAQ about laser steel cutting machine

Can steel laser cutting machine cut wood

Impossible

CO2 lasers are generally used for cutting wood, and the laser wavelength is 10.6um, which can be absorbed by wood. CO2 lasers have their own disadvantages, such as high energy consumption and relatively high maintenance costs in the later period.

What size laser to cut metal

Metal cutting laser cutting format, standard specifications include: 3015, 4015 4020, 6015, 6020, 6025, 8025 and other models.

Laser cutting machine cutting accuracy and size

The cutting accuracy of fiber optic laser cutter is composed of many factors, mainly as follows:

- The size of the laser beam after it passes through the focus.

The smaller the spot, the higher the cutting accuracy, the smaller the slit, and the smallest spot can reach 0.01mm.

- The positioning accuracy of the worktable determines the repeatability of cutting.

The higher the accuracy of the table, the higher the accuracy.

- The greater the thickness of the workpiece, the lower the precision and the larger the kerf.

The laser beam is conical, the slit is conical, and the stainless steel with a thickness of 0.3MM is much smaller than the 2MM slit.

- The material of the workpiece has a certain influence on the accuracy of laser cutting.