Improper storage of metal surfaces can easily cause rust, which can cause metal defects and affect structural performance in the long run. To deal with removing surface rust, oxides, garden tools, or old cars, you need to use rust removal tools. How to clean rust off metal is an essential skill for DIY enthusiasts.

Over time the performance of the metal will deteriorate. It is very important for business owners to remove rust from metal. This article will tell you the best way to rust removal from metal.

Why does metal rust?

Before we delve into rust removal techniques, it’s necessary to understand what rust is and why it poses a threat to metal surfaces.

What is cleans rust?

Rust, scientifically known as iron oxide, is a reddish-brown flaky substance that forms on the surface of iron or steel when it comes into contact with oxygen and moisture. This chemical reaction is called corrosion.

Consequences of rust

Rust can have a variety of harmful effects on metal surfaces, including:

- Structural Weakness: Rust can weaken the affected metal, resulting in reduced strength and durability.

- Aesthetic damage: Rust can become unsightly and damage the appearance of metal objects.

- Impaired functionality: Rust can interfere with the proper functioning of machines and equipment.

- Safety hazards: In some cases, rust can cause structural failure, thereby compromising safety.

Knowing how to get rust off metal can help you save more money and extend the life of sheet metal.

The first thing to consider when cleaning rust off metal is safety. Here are some methods:

- Keep away from children and animals;

- When cleaning off rust, do it in a well-ventilated environment and avoid toxic gases;

- Take protective measures, including safety gloves, protective masks, and protective glasses;

Want rusted things made of metal

- Wire brush or steel wool

- Sandpaper (various grit sizes)

- Rust converter

- Rust remover or solvent

- Paint and primer (if you plan to repaint metal)

- Clean, lint-free rag

- Safety equipment

How to Take Rust off Metal:Fastest Easy Way

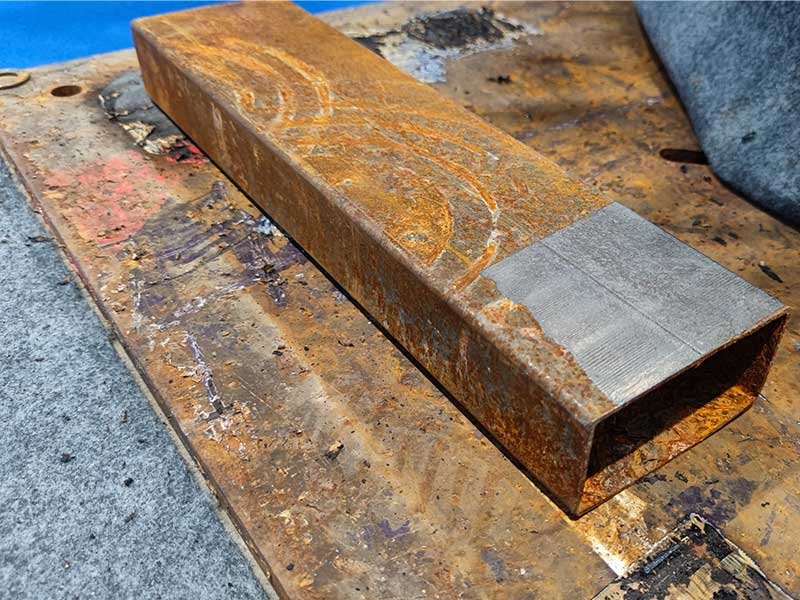

Now that we have a basic understanding of rust, let’s explore various ways to effectively remove it. There are several easiest ways to Dealing with rust on metal. First, you need to choose a metal plate with heavy rust.

Mechanical method

- Wire brush: Use a wire brush or abrasive pad to scrub away surface rust. This method is effective for light rust.

- Sanding: You can use sandpaper or a grinder to remove rust. Coarse grit is suitable for heavy rust, while fine grit is better for light rust.

- Needle rust removers: These tools use multiple needles to remove rust from metal surfaces. They are effective at removing stubborn rust stains.

Chemical method

- Rust converters: Use rust-proof converters according to the These products chemically convert rust into stable compounds that prevent further rust from forming. These products prevent the converter from drying by chemically converting rust into stable compounds, and you can then sand the surface to make it smoother.

- Acid-based rust remover: Phosphoric acid or citric acid-based solutions can dissolve rust. Always follow safety precautions when working with acids.

- Vinegar: Soaking rusty items in vinegar can help loosen the rust and make it easier to wipe away.

Electrolysis

Electrolysis involves immersing a rusty object in an electrolyte solution and applying direct current. This method can effectively remove rust from complex or hard-to-reach areas.

Commercial rust remover:

Use a rust remover or solvent to dissolve rust. Be sure to follow the product’s instructions carefully.

After using the rust remover, rinse the metal surface thoroughly and dry completely.

Recommended article

Methods for preventing rust and maintain it

Protective coating

- Paint: A coat of paint applied to a metal surface inhibits rust by creating a barrier that prevents oxygen and moisture from reaching the metal.

- Galvanizing: Galvanized metal requires a layer of zinc to be coated on the metal to provide excellent protection against rust.

Dehumidification

Controlling the humidity in storage areas can help prevent metal objects from rusting.

Lubricating

Apply lubricant to moving metal parts to prevent rust caused by friction.

Use rust-proof materials

If possible, use rust-resistant alloys such as stainless steel or aluminum for applications where rust is required.

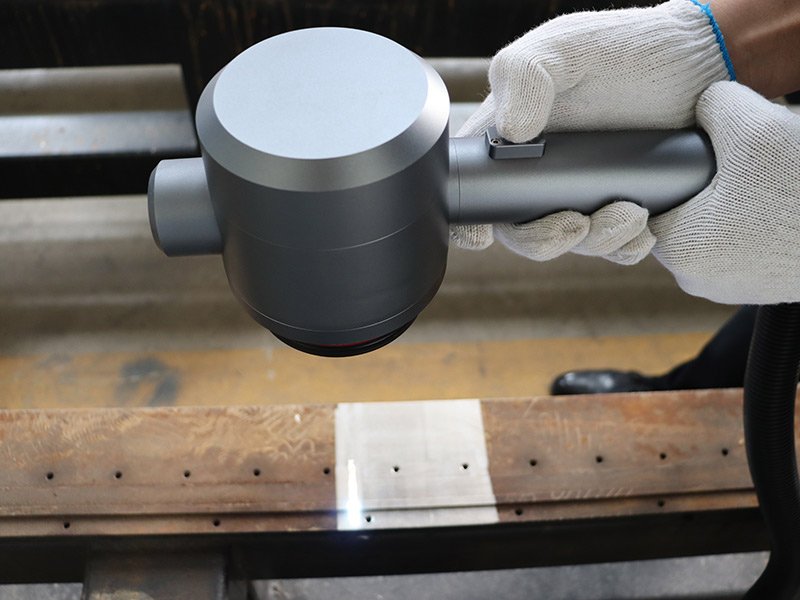

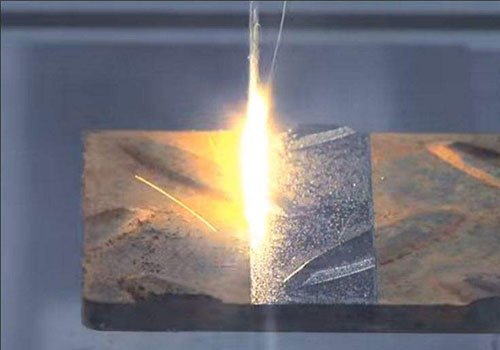

Advantages of Laser Rust Removal

Efficient: Laser rust removal is much faster than traditional mechanical or chemical methods, saving a lot of time and costs.

Precise: Laser rust removal can precisely control the irradiation area and depth to avoid damage or deformation of the metal matrix.

Environmental protection: No harmful waste liquid or dust will be produced, and it will not cause harm to personnel and the environment.

Flexible: Portable, adaptable to various complex working situations. Excitation can be combined with welding, cutting, marking, etc.

- How Does Laser Cleaning Work

- How The Laser Rust Removal Business Is Revolutionizing Cleaning And Maintenance

Laser rust removal requires protective knowledge

The laser beam should not be at the same level as the eyes (that is, the height of the visible laser beam cannot be at the same level as the eyes of a sitting or standing operator);

Staff must wear special anti-laser radiation clothing and protective glasses with corresponding wavelength and laser OD value in the working environment. Laser has certain radiation.

Make sure to wear protective glasses that have a protective effect without obstructing your vision; do not approach areas with laser hazard signs when the laser equipment is working;

When operating laser equipment, you should stay focused and respond to possible laser accidents in a timely manner.

Precaution

In order to ensure the safety of laser production, the following safety precautions should also be noted: Each laser production equipment should be equipped with an emergency stop button and have obvious operating signs;

Laser equipment needs to be maintained at regular intervals, including checking the complete cleaning of the laser lens, replacing the cooling water, laser maintenance and other items;

In particular, check whether the hazard labels on laser equipment are clear and do not fall off.

Enterprises should regularly conduct safety training for employees operating laser equipment, improve laser production management systems, etc.

Conclusion

Metal surface rust removal is a task that can be accomplished with the right tools, materials, and techniques. By following the safety precautions and methods outlined in this guide, you can restore your metal items and ensure they remain rust-free for years to come. Regular maintenance and preventive measures can also help prevent rust and extend the life of metal items.

If you want to know more about How To Clean Rust Off Metal, you can follow us or fill out the form on the right to get the latest laser rust removal machine equipment prices.