Laser technology is increasingly used in industry, especially in surface treatment and material processing. With the increasing demand for efficient, environmentally friendly and precise processing, Power Laser Sander and laser rust removal machines have become two pieces of equipment that have attracted much attention. This article will take an in-depth look at how these two laser devices work, their application areas, and their pros and cons to help you make an informed choice.

Working principle of Power Laser Sander

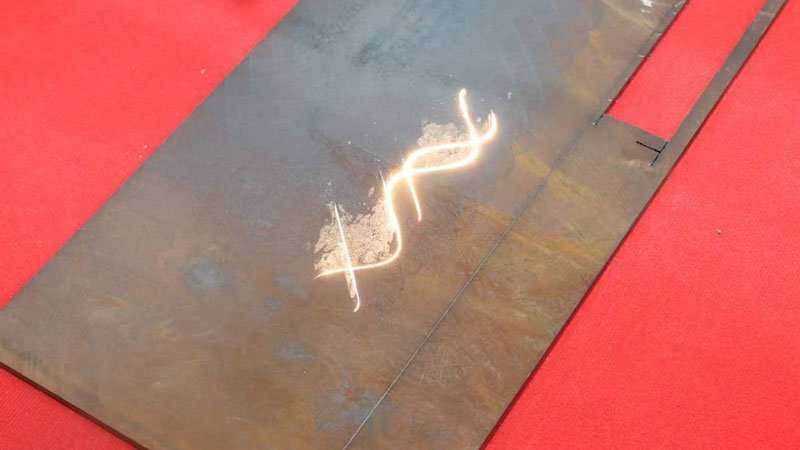

Power Laser Sander uses high-energy laser beams to finely polish the surface of materials. The laser instantly melts or vaporizes tiny protrusions and scratches on the surface of the material through precisely controlled energy density, thereby achieving the effect of removing or smoothing the surface. This method can not only process metals, but also a variety of materials such as wood and plastic.

Power Laser Sander Advantages

- High efficiency

Power Laser Sanders usually have a high power output and can complete sanding tasks quickly. Its laser beam can accurately remove surface materials, significantly improve work efficiency, and is suitable for mass production and industrial applications.

2.Precise control

Laser grinding technology allows the user precise control over the energy and focus of the laser beam. This precision enables power laser sanding to perform high-quality sanding on complex shapes and delicate workpieces without damaging the underlying material.

- Versatility

This equipment can not only be used for polishing metal surfaces, but can also handle wood, plastic and other materials. Its ability to effectively remove rust, paint, dirt and other contaminants has made it widely used in several industries, including automotive repair, furniture manufacturing and the electronics industry.

- Environmentally friendly design

Power laser for sanding uses laser technology that reduces the need for chemical cleaning agents, so less waste and contaminants are generated during the operation. Become an environmentally friendly cleaning solution that meets the requirements of modern industry for sustainable development.

- Easy to operate

Many Power Laser Sander devices are designed to be user-friendly, with easy-to-use control interfaces that allow even novice users to get started quickly. The portable design allows the device to be used flexibly in different work environments.

- Low maintenance costs

Power laser sanding machine is low maintenance compared to traditional sanding methods. Due to its efficiency and durability, users can reduce equipment downtime and maintenance requirements over an extended period of time, thereby increasing overall productivity.

Main Applications

Metalworking: For removing welding spatter, oxide layers and other surface defects.

Woodworking: For fine grinding and improving surface smoothness in furniture manufacturing.

Electronics: For cleaning and grinding of circuit boards.

Working Principle of Laser Rust Removal Machine

The laser rust removal machine ablates the rust on the metal surface by emitting a high-intensity laser beam. The laser energy causes the rust to heat up and evaporate rapidly, thereby effectively removing the corrosive material without damaging the underlying metal.

Advantage

Fast and efficient: It can remove a large amount of rust in a short time and significantly improve work efficiency.

Strong environmental protection: no chemicals are used to reduce environmental pollution.

Cost Savings: Reduces manual cleaning time and subsequent maintenance costs.

Main Applications

Automotive industry: used to clean rust on the car body and chassis.

Shipping industry: remove rust from the hull during ship maintenance.

Construction industry: maintain and maintain steel structures.

Power Laser Sander vs Laser Rust Remover

| Feature | Power Laser Sander | Laser Rust Remover |

|---|---|---|

| Working Principle | Laser ablation for fine polishing | Laser ablation for rust removal |

| Suitable Materials | Metals, wood, and more | Rust and corrosion on metals |

| Efficiency | High for detailed polishing | Extremely high for rapid rust removal |

| Environmental Friendliness | High, reduced chemical usage | Very high, pollution-free technology |

| Cost-effectiveness | Higher initial investment, long-term material savings | Higher initial investment, long-term savings on labor and maintenance |

How to Choose the Right Equipment

Power output: Choose the device with the appropriate power according to the thickness and type of the material being processed.

Portability and ease of use: Portable devices are more suitable for situations that require frequent movement or work in a small space.

Industry requirements: Choose the device that best meets your needs based on the characteristics of your industry (such as automotive, construction, etc.).

Conclusion

When choosing the right device, consider factors such as power output, portability and industry needs. Although the initial investment may be higher, in the long run these devices can significantly save labor and maintenance costs, giving businesses a significant return on investment.

Whether you choose a Power Laser Sander or a laser rust remover, the key is to make an informed decision based on your needs.