With the progress of society and the development of major industries, fiber laser cutting technology has entered everyone’s sight. Many people are curious about the new steel plate laser cutting machine. The following is divided into two parts to give you a brief introduction to the steel plate laser cutting.

Working principle of steel plate metal laser cutter

The fiber laser cutting machine condenses the laser beam into a smaller spot and obtains a high power density at the focal point of the beam, so that the temperature of the material spotted by the laser beam rises sharply and reaches the evaporation temperature instantaneously, causing evaporation and forming holes.

The fiber laser cutting machine takes this as the starting point, and according to the shape requirements of the workpiece to be processed, makes the laser beam and the workpiece move relative to the workpiece according to a certain running track to form a slit.

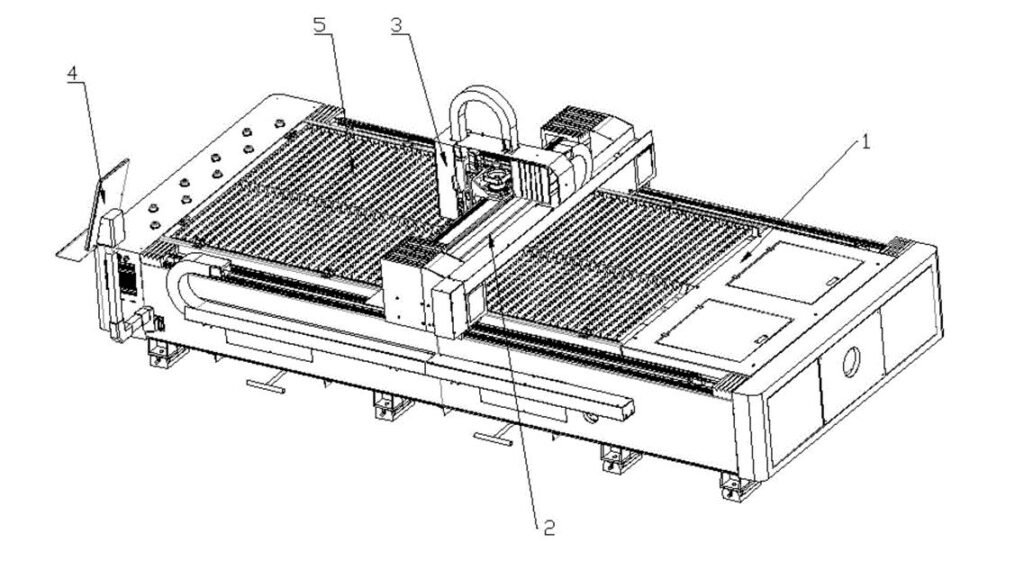

- Storage location of fiber laser

- Beam

- Laser cutting head

- CNC operation display

- Laser cutting machine table

Laser cutting machine type

Laser cutting machines, laser marking machines and laser engraving machines.

Laser cutting machine

is a processing method that irradiates the workpiece with a high-power density laser beam, causing the surface of the irradiated workpiece to quickly melt or vaporize and vaporize at an extremely high speed, thereby forming a cut.

Laser marking machine

A method that uses a laser beam to locally irradiate materials to melt or evaporate the surface of the material, thereby marking a long-term mark on the surface of the material.

Laser engraving machine

Focuses an ordered laser beam onto the surface to be processed. The generated laser beam can instantly melt the surface material and form a spark-like material, thereby transferring the surface material to other locations to form a specific shape. . Because laser beams can create many tiny holes on the surface of materials, laser engraving machines are often used to make precision parts such as films, resins, glass, and PCB boards.

Laser cutting technology VS traditional stamping

Laser cutting is an alternative to traditional stamping technology.

The CNC punch press is a machine tool for sheet metal forming. Its main function is to cut materials. This cannot be replaced by the laser cutting machine. Both still ensure this relative balance.

The advantages of laser cutting mainly include fast cutting speed and high processing accuracy.

| Aspect | Laser Cutting | CNC Punching Machine |

|---|---|---|

| Cutting Speed | More than 10 times faster than CNC punching machines | Lower cutting speed compared to laser cutting |

| Economic Impact | Higher efficiency, leading to economic advantages | Lower efficiency, impacting overall economic viability |

| Cutting Quality | Minimal material loss, no need for secondary processing, superior accuracy | Relatively larger material loss, requires secondary processing, lower precision |

Laser cutting by cutting method

There are two types: contactless and contact.

Non-contact laser cutting machine

A laser beam is used to cut the workpiece, rather than creating high temperatures that melt the material like a plasma arc does. It is mainly used in the field of plate cutting, such as the cutting of plates, pipes, and profiles;

Contact laser cutting machine

The workpiece is heated with a laser beam to partially melt it, and then blown away through a nozzle to form an incision.

Basic structure of laser cut steel plate:

Steel plate laser cutting includes five main aspects, including fiber laser, laser cutting head, cutting operation system, cooling system, and motion system.

- Fiber laser is the core component of fiber cutting machine, and the price is relatively expensive;

- The laser cutting head includes a focusing lens, lens, sensor, nozzle, and other components. The laser beam is irradiated to the surface of the material through the cutting head for processing operations;

- The cutting operating system is installed with professional design software on the computer to control the operation of the entire fiber laser cutting machine;

- In the cooling system, a dual-temperature dual-control laser professional chiller is used to cool the fiber laser, which effectively prevents the lens from deforming or breaking due to excessive temperature.

- The motion system also includes parts such as guide rails, racks and pinions, and servo motors.

During the processing of the fiber laser cutting machine, the processing system should also be equipped with necessary auxiliary blowing devices to remove the slag generated by the slit.

Laser cutting machine applications

steel laser cutting machine is widely used in the production of aviation parts, aircraft frames, wing stringers, tail panels, helicopter main rotors, ceramic insulation tiles, etc.

Non-metallic fields can also cut high-hardness materials, ceramics, silicon nitride, quartz stone, etc.

Flexible cutting, cloth, leather, rubber, plastic plates, etc.

The Fabric Laser Engraving Machine can be used to cut clothes, saving up to 12% of raw materials and labor costs.