After purchasing the metal tube laser cutting, many customers reported many small problems due to improper operation in the later use process. This article tells you how to deal with these problems.

Now we will give a brief introduction on the lubrication of the metal tube tube laser cutting services.

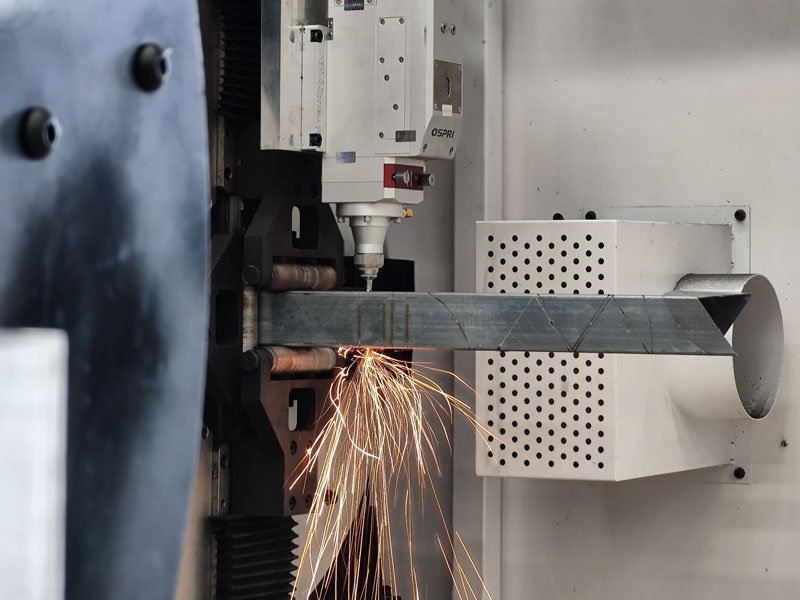

4 Reasons for square tube laser cutting cutting deviation

Metal tube geometry deviation

The surface of the metal pipe is uneven, and the heat of the product during the metal tube cutting process causes the surface of the part to deform, which eventually leads to deviation.

Metal pipe beyond the cutting range

3000W tube laser cutter The thickness of the cutting board is less than 20 thicknesses, the thinner the board, the easier it is to laser cut.

Cutting system programming error

The complex machining trajectory is linearly fitted according to parallel lines, arcs, etc. There is a deviation between the fitted curve and the specific graph, and this deviation prompts the programming part to cause deviation

Focus deviation during square tube laser cutting

During the cutting process of the metal pipe laser cutting machine, there are many changes in the middle part of the pipe that is focused and cut:

- Metal pipe surface gloss

- Fixture of steel parts, image deviation in CNC cutting system software

- Laser tube cutting machines work for a long time, etc. will cause the above things to happen

Lubrication tips for tube cutting laser machine

Due to the higher usage rate and harsh environment, the maintenance requirements of the metal tube laser cutting services are getting higher and higher.

From the perspective of reducing the number of chemicals added, the overall production cost will increase, and the service life of the tools will also be shortened. In the long-term development, reducing the number of chemicals added will cause more problems, such as frequent cleaning of the system. Brings high chemicals and waste liquid treatment costs.

Environmental protection methods in the metal processing industry:

- Reduce the number of chemicals added.

- Use a smaller filter system.

- Application of trace lubrication.

The above method is only suitable for some users

It is a very troublesome problem to be environmentally friendly at work, improve your work efficiency and reduce work costs.

The above three methods cannot achieve a good environmental protection effect in the application of fiber laser tube cutters.

- Negotiate with chemical manufacturers on the required product quantity

- According to the metal pipe processing technology and liquid level management system, to achieve better benefits

- Consider the liquid level and flow according to the progress of production and then manage your system, you can use micro-lubrication to achieve better results.

Minimal lubrication, a small amount of coolant is sprayed quickly on the stubbing contact point for cutting, and any coolant is not recycled. This seems to be a good way to protect the environment, but this method cannot solve all the application problems, in various application fields. Among them, chip removal, rust prevention, and complete cooling are not easily achieved.

If a smaller filter system is used, the metalworking fluid will be overused due to its insufficient filtering capacity and insufficient air contact, and the processing performance will deteriorate, which will increase the corresponding processing costs.

How to prolong the life of laser pipe cutting machine

At present, more and more manufacturers of automatic laser pipe cutting machines are used in various industries. But the cost of a standard laser pipe cutting machine is not low. So for some small and medium-sized enterprises, how to extend the service life of the laser pipe cutting machine is also a very important issue. The high cost of laser pipe cutting machines, if frequently replaced, will bring considerable economic pressure and burden to the enterprise. So doing the maintenance of the laser pipe cutting machine and prolonging the service life are also key issues that enterprises care about.

- Before using the equipment, check the relevant instruction manual, operate the standard process, and ensure the normal use of the equipment

- Pay attention to the daily maintenance of the metal tube laser cutter, keep the bed clean and collect, and replace the liquid in the oil pump in time

- Pay attention to whether the performance of the equipment is in good condition, and deal with abnormalities in time.

Cut the four corners of the square tube to burn

- Increase the oxygen pressure;

- The software improves the synthesis speed of sharp corners;

- The laser cutting head is equipped with a height sensor servo system, the height of the cutting nozzle and the surface plane of the workpiece (the focus remains unchanged)

Round tube laser tube cutting machine sudden power failure

When we use the laser tube cutting machine in Nissan, we will encounter a sudden power failure. How should we deal with it?

The power of the normal working device is suddenly cut off, and the cutting of the pipe is suddenly terminated halfway through. After the call, it needs to be cut again, which affects the work process and consumes a lot of time.

The round tube laser cutter is operated by a numerical control computer system, which contains a memory recovery function. Even if the power is cut off during the working period, after the power is turned on, the last work can continue to operate, which has little effect on the cutting of the workpiece.

FAQ:

How big a tube can heavy-duty tube laser cutting cut

The cutting thickness of laser cutting pipe is determined according to the size of the power. Generally, it can cut about 0.1mm–10mm.

Pipe cutting machine power on the market: 1000w 1500w 2000w 3000w 6000w

The special laser cutter for pipes can realize seamless pipe cutting, round hole cutting, square cutting, etc. Hole cutting, irregular pattern cutting

What are the consumables for tube laser cutting services?

The consumables of laser pipe cutting machine are gas, cutting lens, focusing lens, nozzle, ceramic body, etc.

What should I do if the pipe is deformed during cutting and the cutting surface is inclined?

Strengthen the skills of operators, strengthen training, master the control system proficiently, and improve the quality of cutting.

DOWELL cnc laser cutting tube machine factory has 13 years of laser cutting equipment manufacturing experience. We can provide china tube fiber laser cutting, metal tube laser cutter. We can provide cutting of 500w 1000w 1500w 2000w 3000w aluminum pipe, carbon steel pipe, stainless steel, channel steel and other pipes, and provide you with the cheapest discount price in the market.

If you are interested in the industrial metal tube laser cutting, welcome to subscribe to my channel.

You can also request a quote for our cnc tube fiber metal laser cutting in the following ways: you can follow 86-18654506392

Related articles

How Much Does A Tube Laser Cutter Cost