In modern manufacturing, tubes are widely used in the industrial market, among which laser cutting and plasma cutting are the two most commonly used methods. Each has its own advantages in terms of precision, efficiency, cost, etc. How to choose between the two is a headache for many buyers.

This article will conduct an in-depth comparative analysis of Tube Laser Cutting vs. Plasma Cutting, providing you with a comprehensive purchase guide.

Tube Laser Cutting vs. Plasma Cutting Pros and Cons

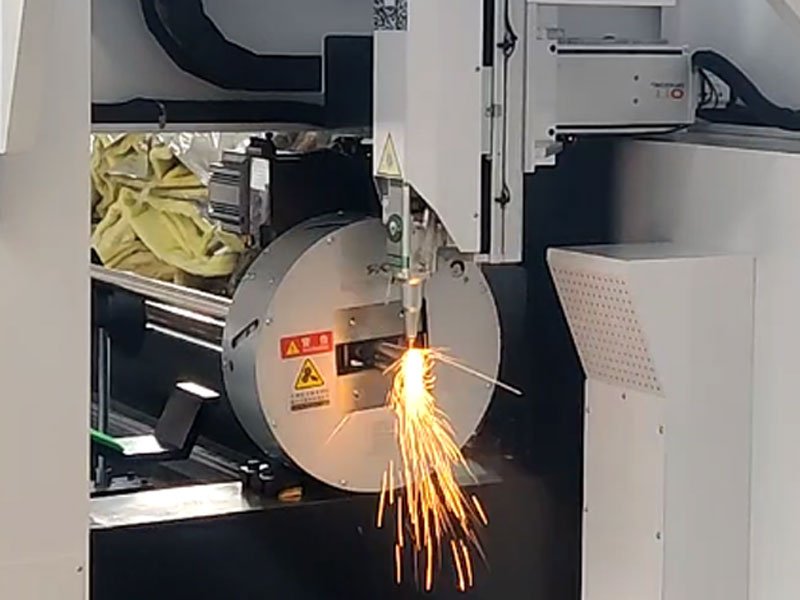

What is a Laser Tube Cutting Machine

Laser cutting uses a high-energy-density laser beam to irradiate the surface of the workpiece, causing the material to partially melt or vaporize, and blows away the molten material through auxiliary gas to achieve cutting.

What is a Plasma Pipe Cutter

Plasma cutting uses the heat generated by a high-temperature plasma arc to melt the metal, and uses a high-speed airflow to blow away the molten metal pipe to achieve cutting.

Pros and Cons

| Feature | Tube Laser Cutting | Plasma Cutting |

|---|---|---|

| Accuracy | High accuracy, narrow kerf, smooth cut | Lower accuracy, rougher cut, larger heat-affected zone |

| Speed | High speed, high efficiency | High speed, especially for thick plates |

| Material | Can cut a variety of materials, including metals and non-metals | Primarily for conductive metals |

| Cost | High equipment investment but lower long-term operating costs | Lower equipment investment but higher operating costs |

| Heat-affected zone | Small heat-affected zone, less material distortion | Larger heat-affected zone |

Different Cutting Materials:

Tube laser cutting: can be used for a variety of metal materials, such as carbon steel, stainless steel and aluminum, but there are certain restrictions on the thickness of the material.

Plasma cutting: mainly used for cutting thicker metal plates, especially for cutting conductive metals such as aluminum and copper.

Tube Laser Cutting Vs Plasma Cutting Cost

Tube laser cutting: Laser cutting equipment has a high investment, but its long-term operating cost is relatively low, suitable for enterprises that require high-frequency cutting.

Plasma pipe cutting machine: Plasma cutting equipment has a low investment, but its operating cost is relatively high, suitable for small-scale processing.

Tube Laser Cutting Vs Plasma Pipe Cutter Applications

- Tube Laser Cutting: Widely used in industries such as aerospace, automotive, and precision manufacturing where high-quality cuts and intricate designs are necessary. It is particularly effective for applications like bracket fabrication, frame manufacturing, and other custom parts.

- Plasma tube cutter: Commonly used in heavy fabrication, shipbuilding, and construction. It is preferred for cutting thicker materials quickly and is often used for applications where speed is prioritized over finish quality.

Classification of Tube Laser Cutting Machine Vs Plasma Cutting Machine

Fiber Laser Cutting Machine Vs. Co2 Laser Cutting Machine

- Fiber laser: It has the advantages of high efficiency, high beam quality, and low maintenance cost, and is suitable for precision cutting and thin plate cutting.

- CO2 laser: It has high power and is suitable for cutting thick plates, but it is bulky and has high maintenance cost.

Cnc Tube Laser Cutting Machine Vs. Manual Laser Cutting Machine

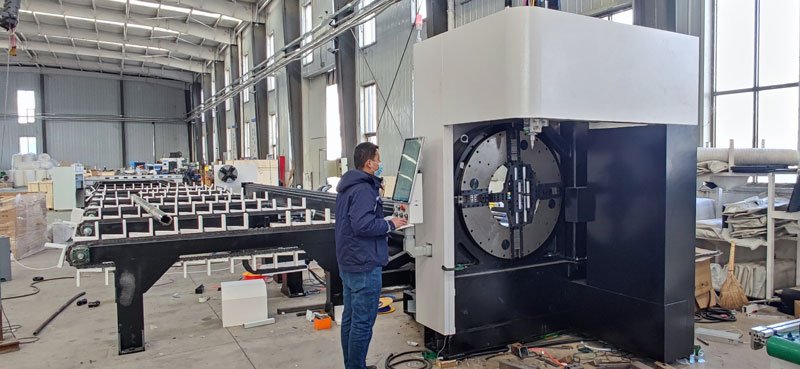

- CNC tube laser cutting machine: It has high automation, high cutting accuracy, good repeatability, and is suitable for mass production.

- Manual laser cutting machine: It is simple to operate, but has low efficiency and low precision, and is suitable for small batch production.

Comparison of 2d and 3D Tube Laser Cutting

- Cutting method: 2D laser cutting is mainly used to cut flat graphics, while 3D laser cutting can cut complex three-dimensional graphics.

- Application range: 2D laser cutting is suitable for cutting ordinary tubes, while 3D laser cutting can be used for tubes of various complex shapes to meet the needs of different industries.

Environmental Impact

- CNC tube cutter: produces less waste and minimal fumes or harmful emissions, making it a more environmentally friendly option.

- Plasma tube cutting machine: produces a lot of heat and fumes, which has a greater impact on the environment. Proper ventilation and safety measures are needed to mitigate these effects.

Conclusion

This article makes a detailed comparative analysis of tube laser cutting and plasma cutting, and provides users with a comprehensive selection guide based on actual application scenarios. I hope this article can help you better understand tube cutting technology and choose the equipment that suits you.

FAQ

Which is better, laser cutting or plasma cutting for pipes?

It depends on your specific needs, such as cutting materials, precision requirements, budget, etc. Laser cutting has higher precision but higher cost; plasma cutting has lower cost but lower precision.

What are the advantages of CNC pipe laser cutting machine?

CNC pipe laser cutting machine has high automation, high precision, high efficiency, and is suitable for mass production.

How to choose a suitable pipe cutting machine?

Consider factors such as materials, precision, efficiency, and budget.

Is pipe laser cutting safe?

Pipe laser cutting is dangerous and must comply with safety operating procedures.