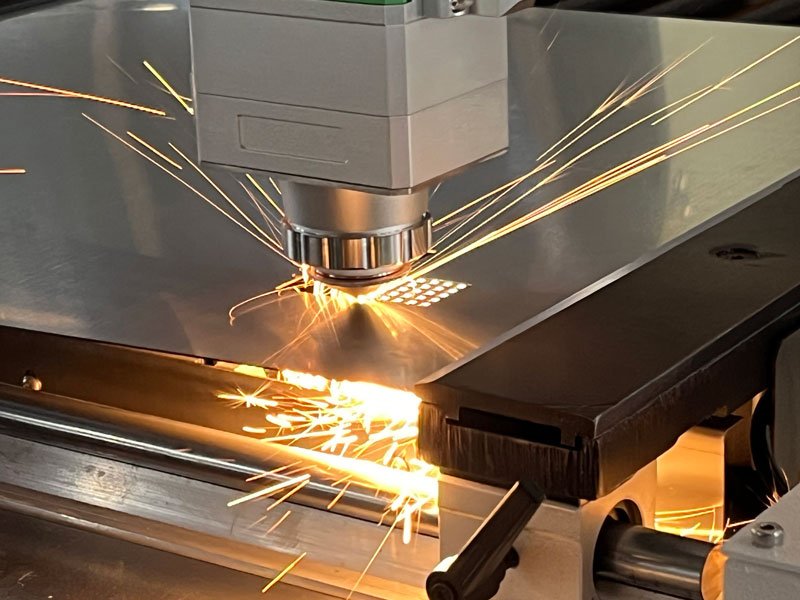

With the rapid development of the industrial market and the rapid rise of laser cutting technology in the industrial market, the advantages and disadvantages of laser cutting are confusing to many primary buyers.

Now this article will give you a comprehensive and systematic introduction to the benefits of laser cutting.

What Is a Laser Cutter Used for

Different laser cutting machines can cut different materials, such as wood, plywood, glass, leather, acrylic, and some can cut metal, stainless steel, carbon steel, aluminum plate, galvanized plate and other metal materials. Different cutting processes produce different cutting effects.

China Best Top 20 Laser Cutting Machine Exporters

Types and Characteristics of Laser Cutting

Laser cutting machines can be divided into CO2 laser cutting machines and fiber laser cutting machines according to the type of laser.

- CO2 laser cutting machine: Longer wavelength, faster cutting speed, suitable for cutting non-metallic materials and some metal materials.

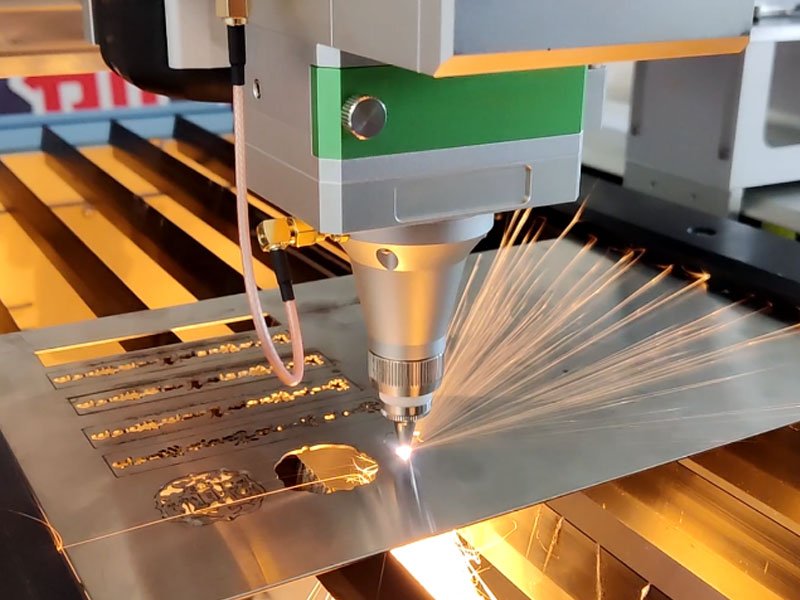

- Fiber laser cutting machine: Shorter wavelength, high beam quality, high cutting accuracy, suitable for cutting various metal materials, especially stainless steel and carbon steel.

What Are the Advantages of Laser Cutting

Fast speed:

can work continuously, and use the CNC system to accurately control the cutting accuracy;

High precision:

High-energy laser beam cutting can perfectly control the cutting accuracy. The minimum cutting width can reach several millimeters, so it can be used in fields that require high sheet metal precision.Different power laser cutting accuracy is also different.

Non-contact cutting:

No damage to the workpiece.

The width and depth of the cut are adjustable:

you can choose the material you want to cut,

By selecting the appropriate power, a wide size of incision can be achieved by focusing the laser spot.

Unlimited cutting graphics:

Complex craft images can be perfectly cut, including curves, circles and sharp angles. Suitable for mass production and processing.

What Are the Benefits of Laser Cutting Tools

Good processing quality and low labor cost

In the actual processing and production process, we will find that the processing quality is very high and the entire cutting process is very fast. The processing and production advantages of high-quality products are more obvious, and the appearance is smoother and cleaner.

Automatic typesetting saves materials and reduces production costs

The choice of laser cutting is also not limited to cutting patterns. Automatic typesetting can now be used to save materials. The entire cutting surface is smooth and clean, and the processing cost is low.

The above is about the advantages and disadvantages of laser cutting. If you want to know more about some laser cutting equipment, you can consult us to get the latest equipment prices and product catalogs.

High precision, effectively improve productivity

As an alternative to shearing and flushing, laser cutting technology is accurate, flexible and efficient, and can effectively process various complex parts. As long as the graphics are cut and the control system is entered, the cutting size can be set, helping to directly shorten the product processing and manufacturing cycle, effectively Improve labor productivity.

Benefits: low maintenance cost and high cost performance

The maintenance of mechanical products is very expensive. Laser cutting machines have stable performance, are sturdy and durable, can work continuously and are not easily damaged. They have great advantages in terms of later maintenance costs.

Disadvantages of Laser Cutting

High initial cost

Laser cutting machines are expensive to purchase and install, making them a sizeable investment, especially for small and medium-sized businesses. The high upfront cost can be a barrier for companies that do not require high-volume production.

Maintenance and operating expenses

Operating a laser cutting machine requires regular maintenance, such as replacing the laser tube and optics. These maintenance requirements, as well as the cost of skilled labor to manage the equipment, can increase overall operating expenses.

Limitations of materials

Laser cutting performs exceptionally well on thin to medium-thick materials, but its efficiency and quality decrease as the material becomes thicker. Plasma cutting, on the other hand, may be better suited for thicker materials, especially metals.

High energy consumption

Laser cutting machines consume a lot of electricity, especially when running continuously. This energy demand can increase operating costs, especially for facilities that aim to save energy.

Safety issues

Laser cutting requires trained operators due to potential hazards, such as laser radiation. Operators must follow strict safety protocols to prevent health risks, which can complicate operations and require additional training or protective equipment.

Applications of Laser Cutting

- Automotive Industry: Used to cut intricate parts with precision, essential for automotive designs.

- Aerospace Industry: In aircraft manufacturing, laser cutting is used for lightweight, durable parts.

- Electronics Manufacturing: Precise cutting for circuit boards and electronic components.

Laser Cutting vs. Other Cutting Methods

Comparing laser cutting to other methods, such as plasma cutting and waterjet cutting, provides insight into its unique benefits and drawbacks:

- Plasma Cutting: Effective for thicker materials but less precise than laser cutting.

- Waterjet Cutting: Can cut through very thick materials without heat distortion, but typically slower and less precise for intricate designs.

Future Development Trend of Laser Cutting

Intelligentization: The combination of laser cutting with artificial intelligence and automation technology to achieve intelligent production.

New material cutting: The application prospects of laser cutting in cutting new materials (such as composite materials, ceramics, etc.).

Micro-nano processing: The application of laser cutting at the micro-nano scale, and its potential in microelectronics, biomedicine and other fields.

Conclusion

Laser cutting offers unparalleled precision, speed, and versatility, making it a powerful tool for modern manufacturing. While it presents high initial and operational costs and has limitations with thicker materials, its benefits often outweigh these drawbacks in industries requiring precise, high-volume production. Choosing laser cutting depends on specific production needs and industry requirements, but it remains a cornerstone technology for high-quality, efficient cutting.

FAQ

What is laser cutting, and how does it work?

Laser cutting uses a high-powered laser to precisely cut materials by focusing intense light energy on a small area, melting or vaporizing the material in the process.

What materials can be cut with laser cutting technology?

Laser cutting can process a wide range of materials, including metals, plastics, wood, and ceramics, making it versatile for multiple industries.

What are the main benefits of laser cutting compared to other cutting methods?

Laser cutting offers high precision, fast speeds, and minimal waste, making it ideal for detailed and efficient manufacturing applications.

What are the laser cutting limitations in terms of material thickness?

Laser cutting works best with thin to medium-thick materials; its effectiveness and quality decrease when cutting very thick materials.

How much maintenance does a laser cutting machine require?

Laser cutting machines require regular maintenance, such as replacing laser tubes and lenses, which can add to operating costs but ensure consistent performance.