Are you still worried about the unsightly welding effect and low efficiency? Laser welding may bring you a surprise! With the rapid development of laser welding techniques, the heat-affected zone, welding quality, and high precision are favored by the small industrial market. However, there are still many customers who have questions such as “Is laser welding effective?” “Are handheld laser welders any good“, “Are laser welders worth it?”

This article will take you to explore the information of laser welding technology in depth, and help you fully understand whether the handheld laser welding machine is suitable for your production needs.

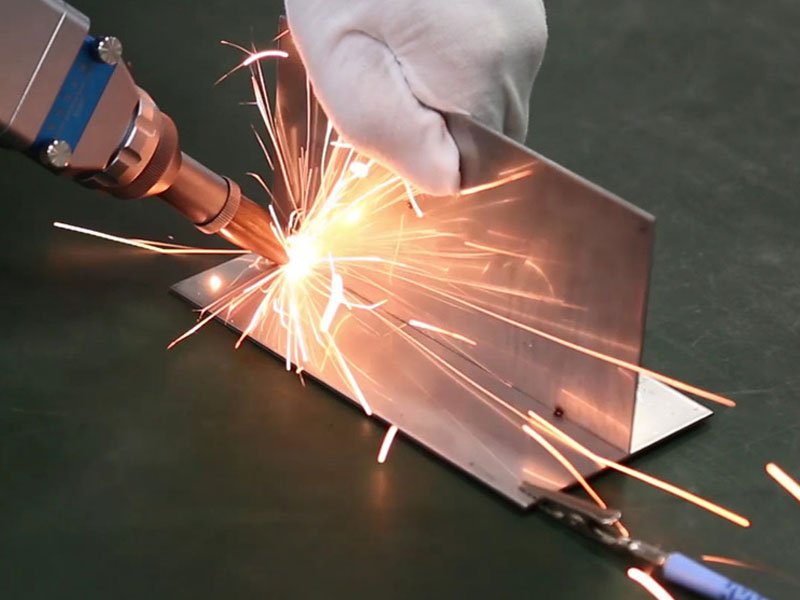

Laser Welder Video

Principle of Laser Welding Process

Laser welds use a high energy density laser beam to heat the metal material to a molten state to form a weld. Compared with traditional welding methods (such as arc welding or gas welding), laser welding has a higher energy concentration and a smaller heat-affected zone. This means that during the welding process using a laser, there is less thermal impact on the surrounding material, resulting in less deformation and stress.

- 6 Welding Modes about Handheld Laser Welding Machine

- What is the Laser Welding Thickness

- Laser Welding Vs Traditional Welding

- Air Cooled Laser Welder VS Water Cooled Laser Welder

Laser Beam Welder Advantages:

High precision: hand laser welder can achieve very fine welds, suitable for applications requiring high-precision connections.

Fast: The speed of laser hand welding is 5 to 10 times that of traditional methods, which significantly improves production efficiency and is especially suitable for mass production.

Small heat-affected zone: laser weld has a small heat-affected zone, which reduces thermal deformation and stress concentration and improves welding quality.

Can weld a variety of materials: Laser welding can handle a variety of materials, including reflective metals that are difficult to weld (including stainless steel, aluminum alloys, copper, titanium alloys, etc.), expanding its application range.

High degree of automation: Laser equipment is easy to integrate with robots and CNC systems to achieve automated production and improve consistency and stability.

Beautiful welds: The welds produced by hand held laser welding are flat and smooth, requiring no subsequent grinding or cleaning. Post-processing costs are reduced and the safety of the work environment is improved.

Disadvantages of Laser Welding

High initial investment: The purchase cost of hand held lazer welder is high, usually two to three times that of traditional welding equipment, which is a big problem for small businesses with limited budgets.

High requirements for workpiece matching accuracy: Laser welding has strict requirements on workpiece gap and alignment, and it is necessary to ensure that the upstream and downstream processes meet the standards, otherwise it may cause quality problems.

High requirements for the operating environment: The laser beam welding machine has high requirements for the cleanliness of the environment, and corresponding protective measures need to be taken.

High technical requirements for operators: The operation of laser welder hand held requires certain professional knowledge and skills.

Application Areas of Metal Laser Welding:

Electronic industry: welding of mobile phones, computers, and electronic components.

Automobile manufacturing: welding of car bodies, chassis, and battery packs.

Medical devices: welding of medical devices such as artificial joints and implants.

Aerospace: welding of aircraft and spacecraft components.

Jewelry: welding of gold and silver jewelry.

How to Choose the Right Welding Using a Laser

Laser type: CO2 laser, solid laser, fiber laser, etc. Different types of lasers are suitable for different welding materials and thicknesses.

Laser power: Select the appropriate laser power according to the thickness of the welding material and the welding speed.

Beam quality: The beam quality affects the welding effect. Generally speaking, the better the beam quality, the better the welding effect.

Automation degree: Select laser welsing machines with different automation degrees according to production needs.

Is laser welding safe?

CNC laser welding is safe, provided that proper safety measures and operating specifications are followed. The laser beam used in the laser welding process has a high energy density and can cause damage to the eyes and skin, so necessary protective measures must be taken. Here are some key points to ensure the safety of the lazer welding machine:

- Personal protective equipment: All people operating the lazer welding machine should wear laser safety glasses to prevent direct or indirect contact with the laser beam. Welders should also use helmets designed specifically for laser welding, which can absorb and reflect infrared lasers while protecting the eyes from visible light.

- Working environment: The laser welder machine should be carried out in a specially designated “laser control area” that should be properly shielded to prevent unauthorized personnel from entering and being affected by laser radiation. Flammable materials and highly reflective materials should be avoided around to reduce the risk of accidental reflections.

- Operating specifications: The laser welding gun should be kept at an angle between 30° and 70° and always pointed away from yourself and others to prevent injuries caused by laser reflections.

Are Handheld Laser Welders Easy to Operate?

Handheld laser welders are relatively easy to operate and suitable for users of all skill levels.

Short learning curve: Handheld laser welders are relatively simple to operate, and users can usually master basic operating skills in a short period of time. This allows even beginners to quickly get started with welding work.

Flexibility: Handheld devices allow operators to weld in different positions and angles, suitable for complex shapes and hard-to-reach areas. This flexibility makes handheld laser welders very popular for small jobs and on-site repairs.

Efficiency: Handheld laser welders can quickly produce high-quality welds, reducing subsequent processing work, thereby improving overall work efficiency.

Although handheld laser welders are easy to operate, users still need to receive proper training to ensure safe and effective use of the equipment. By following the operating guidelines and safety recommendations provided by the manufacturer, users can make the most of this advanced technology.

Conclusion

Laser welding technology is changing the way we manufacture. If you want to learn how laser welding can bring value to your business, you are welcome to contact us. We will provide you with professional consulting services to help you choose the most suitable laser welding solution.

FAQ

Are Laser Welders Any Good for Steel

Yes, laser welders are excellent for steel.

How Much Does Laser Welding Cost?

Although the initial investment of a handheld laser welder is high, its high efficiency and low post-processing costs usually make up for this expense in the long run. Users can achieve cost benefits by reducing rework and improving production efficiency

Does It Require Training to Use a Laser Welder?

Yes, before operating a laser welder, users should receive professional training to understand the working principle, safety precautions and operating procedures of the equipment. This helps to ensure safety and improve welding quality.

Does the Laser Welding Process Produce Harmful Fumes?

Yes, the laser welding process produces fumes and particles, which may have long-term effects on health. Therefore, a dedicated fume removal device should be equipped to ensure a safe working environment

Related Articles

- The Truth About Handheld Laser Welder Cost

- Lightweld Laser Welder Be Used How Long

- What is Laser Welding? A Comprehensive Guide for Beginners

- Guide of Laser Welding Stainless Steel

- What Is the Difference Between Laser Welding Vs Arc Welding

- What about Laser Welding Strength

- Application of Laser Welding Galvanized Steel