With the rapid development of laser technology, the laser cleaning market is increasingly recognized by users. Do you want to know more about laser cleaning machine for metal rust? Then this article will be helpful to you.

What is a Laser Cleaning Machine

Laser cleaning machines for metal are advanced devices that utilize high-intensity laser beams to remove contaminants, rust, coatings, and other unwanted materials from metal surfaces. This non-contact cleaning method offers precision, efficiency, and environmental benefits over traditional cleaning techniques.

- How Does Laser Cleaning Work

- How Much Does A Cheapest Laser Cleaning Machine Cost

- Understanding Laser Cleaning Cost Per Hour

The Role of Metal Cleaning in Various Industries

It is essential to maintain equipment efficiency, prepare surfaces for coating, and ensure product quality in manufacturing, aerospace, automotive, and other industries.

Types of Types of lasers used in metal cleaning

- Fiber lasers

- Nd:YAG lasers

- CO2 lasers (less common for metals)

Advantages And Disadvantages Of Industrial Laser Cleaning Equipment

What is a laser cleaning machine used for

Automotive Manufacturing

- Engine Component Cleaning

- Removes oil, carbon deposits, and other contaminants from engine blocks, pistons, and valves

- Improves engine performance and fuel efficiency

- Prepares surfaces for inspection, reducing the risk of overlooking defects

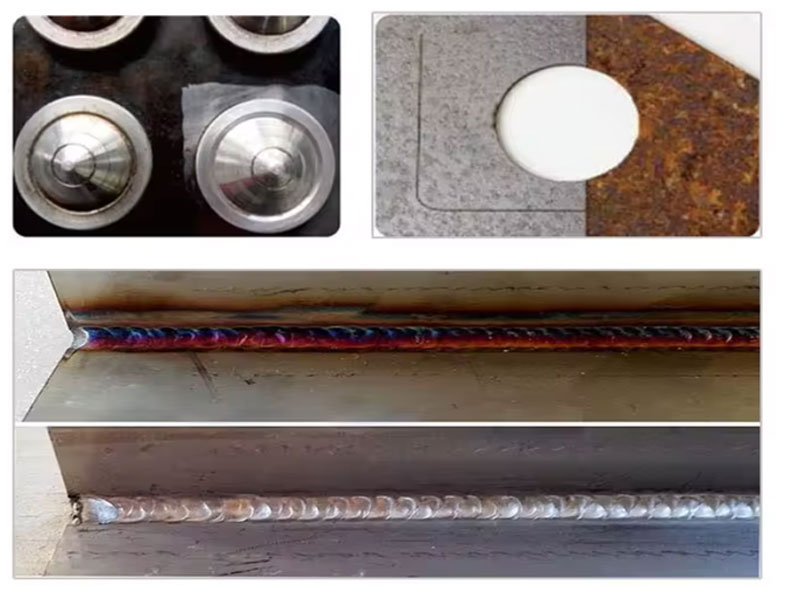

- Surface Preparation for Welding

- Cleans metal surfaces before welding, removing oxides and contaminants

- Improves weld quality and strength

- Reduces the risk of weld defects caused by impurities

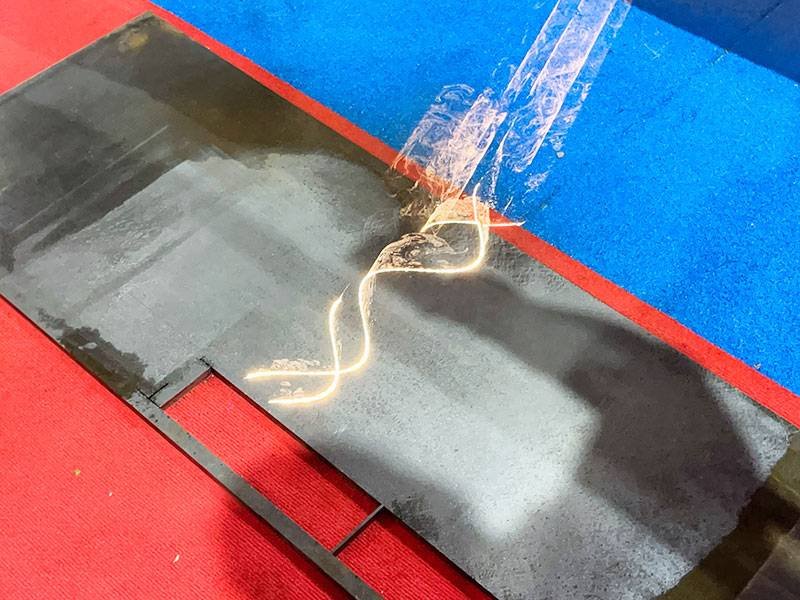

- Paint and Coating Removal

- Selectively removes old paint or coatings without damaging the underlying metal

- Prepares surfaces for repainting or powder coating

- Useful in automotive restoration and repair

- Mold and Tool Cleaning

- Removes residues and contaminants from injection molds and stamping tools

- Extends the life of expensive tooling

- Improves part quality by ensuring clean mold surfaces

Aerospace Industry

- Turbine Blade Cleaning

- Removes oxide layers and contaminants from turbine blades

- Improves engine efficiency and performance

- Extends the lifespan of critical engine components

- Aircraft Part Decoating

- Safely removes paint and coatings from aluminum, titanium, and composite parts

- Prepares surfaces for non-destructive testing (NDT) and inspection

- Allows for reapplication of specialized coatings

- Surface Preparation for Bonding

- Cleans and prepares surfaces for adhesive bonding in composite structures

- Improves bond strength and reliability

- Critical for ensuring structural integrity in aircraft components

- Landing Gear Maintenance

- Removes corrosion, paint, and hydraulic fluid residues from landing gear components

- Prepares surfaces for inspection and recoating

- Improves safety and extends component lifespan

Electronics Industry

- Circuit Board Cleaning

- Removes flux residues, oxidation, and contaminants from PCBs

- Prepares boards for conformal coating or further assembly

- Improves electrical conductivity and reduces the risk of short circuits

- Surface Preparation for Soldering

- Cleans contact pads and component leads before soldering

- Improves solder joint quality and reliability

- Reduces defects in electronic assemblies

- Conformal Coating Removal

- Selectively removes conformal coatings for board rework or component replacement

- Allows for precise cleaning without damaging sensitive components

- Improves efficiency in electronics repair and modification

- Connector and Contact Cleaning

- Removes oxidation and contaminants from electrical connectors and contacts

- Improves electrical conductivity and signal integrity

- Extends the lifespan of expensive connectors

Restoration and Conservation

- Historical Artifact Cleaning

- Gently removes corrosion, dirt, and unwanted patina from metal artifacts

- Preserves delicate surface details and engravings

- Allows for controlled cleaning of valuable historical objects

- Sculpture and Monument Restoration

- Removes environmental contaminants, graffiti, and corrosion from outdoor sculptures

- Restores the original appearance of metal artworks

- Can be adjusted to preserve desired patinas

- Archaeological Metal Cleaning

- Carefully removes encrustation and corrosion from archaeological finds

- Reveals hidden details and markings on ancient metal objects

- Aids in the study and preservation of historical metalwork

Industrial Maintenance

- Industrial Mold and Tool Cleaning

- Removes residues, release agents, and oxidation from large industrial molds

- Improves product quality in plastic injection molding and metal casting

- Reduces downtime associated with manual cleaning methods

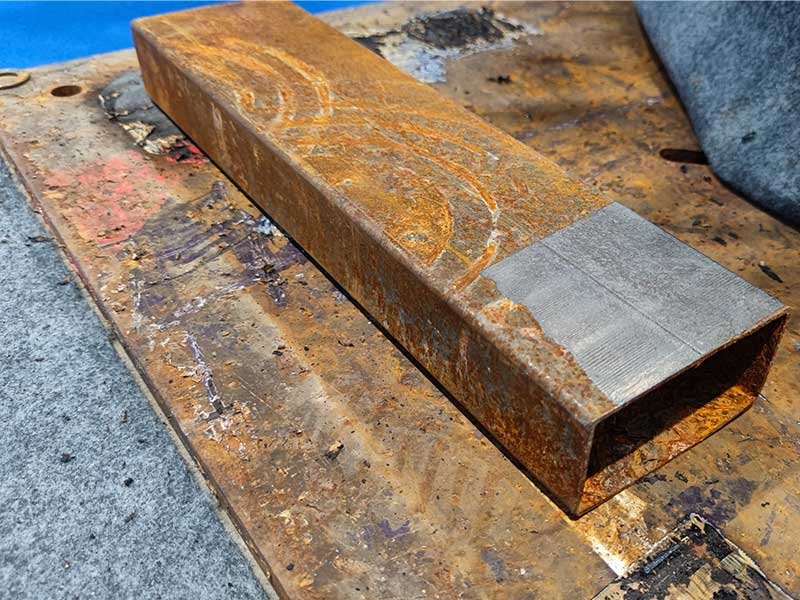

- Rust and Corrosion Removal

- Efficiently removes rust and corrosion from large metal structures

- Prepares surfaces for recoating or inspection in bridges, ships, and industrial equipment

- Can be used for in-situ cleaning of installed equipment

- Welding Equipment Maintenance

- Cleans welding nozzles, wire guides, and other welding equipment

- Improves welding quality and reduces defects

- Extends the life of welding equipment

- Petrochemical and Power Generation Facilities

- Cleans heat exchangers, turbines, and pipelines

- Removes scale, oxidation, and contaminants without chemical agents

- Improves efficiency and safety in critical industrial processes

Comparison with Traditional Metal Cleaning Methods

A. Sandblasting

- Pros: Effective for heavy contamination

- Cons: Abrasive, creates waste, can damage soft metals

B. Chemical cleaning

- Pros: Can dissolve tough contaminants

- Cons: Environmental concerns, potential health hazards

C. Abrasive cleaning

- Pros: Simple and widely available

- Cons: Can alter surface finish, not suitable for precision cleaning

Differences Between Laser Cleaning VS Sandblasting

How to Choose a Laser Cleaning Machine for Removing Metal Rust

Laser Type and Power:

- Pulse laser: Offers precise control, minimal heat impact, suitable for delicate surfaces.

- Continuous wave laser: Efficient for large areas and thick rust layers, but can generate more heat.

- Power output: Determines cleaning speed and depth. Higher power is generally better for heavy rust, but consider the risk of damaging the base metal.

Wavelength:

- The laser wavelength should be efficiently absorbed by the rust to maximize cleaning efficiency.

- Common choices include UV, visible, and near-infrared wavelengths.

Delivery System:

- Handheld: Flexible for irregular surfaces and small-scale operations.

- Automated: Ideal for high-volume production and consistent results.

Cleaning Depth:

- Determine the required depth of rust removal to select the appropriate laser power and pulse duration.

Metal Type:

- Different metals have varying heat sensitivities. Consider the laser’s impact on the base metal.

Production Volume:

- High-volume production may require automated systems with higher power lasers for efficiency.

Safety Features:

Ensure the machine complies with safety standards and includes essential safety features like laser safety interlocks and protective eyewear.

Industrial Laser Cleaning Vs Dry Ice Blasting, Which One Is More Suitable?