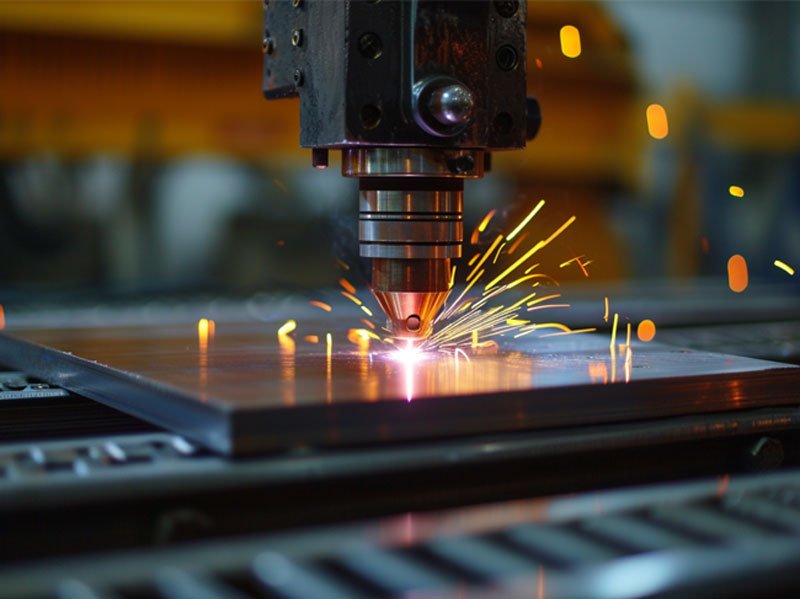

In the construction industry, steel structure is an important structural form. To accurately process h beam components, plasma cutting is commonly used in the market. This article will introduce the laser beam cutting machine method and explain its advantages and disadvantages.

What is laser beam cutting machine?

Laser Beam Machine (Laser cutting Machine) is a processing equipment that uses laser for cutting. Laser beam cutting can cut various metal and non-metal materials, and has the advantages of high cutting accuracy, fast speed, and small heat affected zone.

- What Are the Disadvantages of Laser Cutting

- What Is the laser beam cutting process

- How to Operate Laser Cutting Machine

How much is a laser beam cutting machine price?

Laser beam cutting machines are mostly used in metal cutting in the industrial market, and the price is usually between $20,000 and $200,000. This is mainly related to the configuration of the equipment, the size of the power, the manufacturer’s brand, capacity, and after-sales services. The cost of equipment used in non-metals is relatively low, and the cost of small household applications ranges from $2,000 to $15,000.

Cutting speed of laser beam machining

Generally speaking, the cutting speed of a laser cutting machine can vary between 30 and 500 times per minute. Among them, the cutting speed of low-density materials such as wood, plastic or rubber is often faster, while the cutting speed of high-density materials such as steel, copper and aluminum is much slower.

Temperature of laser cutting beam

The temperature of the laser emitted by the laser cutting machine is usually between 5500 degrees and 6000 degrees.

Principle of laser cutting machine light source

The light source of the laser cutting machine is a laser. The laser is a light source that uses repeated collisions between photons emitted during the stimulated radiation process of special materials to convert laser energy into coherent light. Since laser uses energy to excite materials and emit energy, the temperature of the laser cutting machine’s light source is very high.

Effect of temperature on laser

The temperature of the laser cutting machine light source has an important impact on the power density, wavelength, speed, energy and other aspects of the laser. Generally speaking, the higher the temperature of the laser cutting machine light source, the greater the power density of the laser, and the shorter the wavelength of the laser, the speed will increase accordingly.

At the same time, the temperature of the laser cutting machine’s light source will also affect the energy density and quality of the laser, thereby affecting the cutting effect of the laser cutting machine.

Laser temperature range

Generally speaking, the laser light emitted by a laser cutting machine is usually between 5500 degrees and 6000 degrees. In addition, the temperature of the laser cutting machine’s light source will vary depending on its working environment and the type of material being cut. When using a laser cutting machine, you must pay attention to protect your own safety.

- Laser Cutter Safety Comprehensive Standards Guidelines

- Laser Cutting Operators: A Guide to Fiber Laser Safety Glasses

- 7 Must-See Laser Cutter Safety Precautions

- What Does CNC Laser Cutting Machine Operator Do?