The industrial manufacturing industry requires higher and higher precision for sheet metal cutting, and many beginner laser users are curious about “what is the process of laser cutting” and “how does a laser cutter work step by step”. This article will focus on these contents.

What is laser cutting

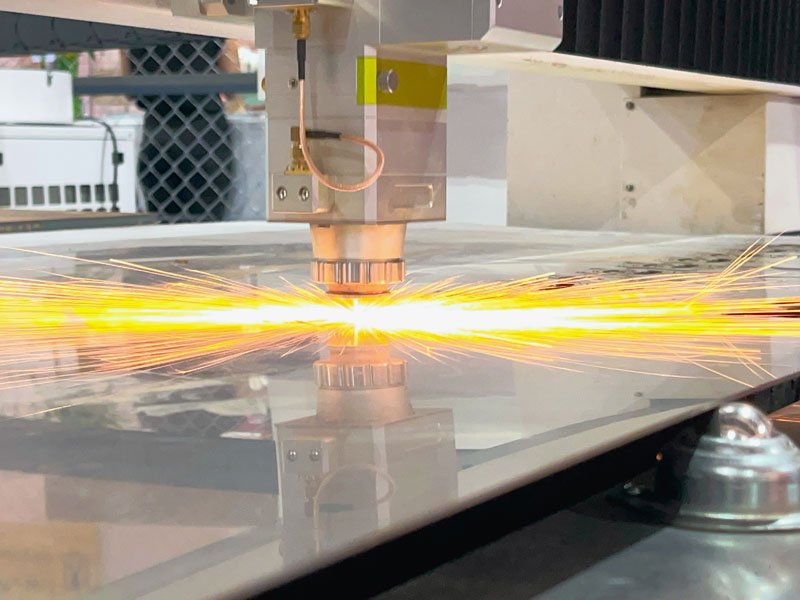

Laser cutting technology is a heat separation process in which high-energy heat is generated by the laser and concentrated on a single focus. Through reactions such as gasification, the metal sheet is penetrated to achieve the effect of cutting. Laser cutting technique capable of carving slits as narrow as 0.1 millimeters.

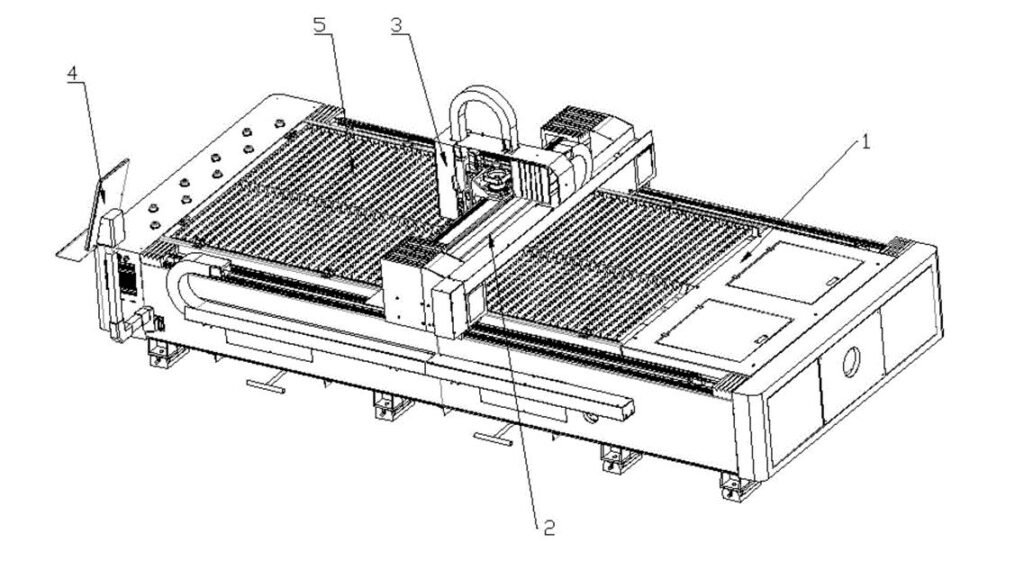

Laser cutting system configuration

The laser cutting machine configuration mainly includes Fiber lasers, Laser cutter head, control system, drive system, machine tool, cooling system, and optical system.

Laser source

The laser source is one of the most critical components of a laser cutting machine, and its stability and power affect the cutting effect and speed. Common laser sources on the market include CO2 laser tubes, fiber lasers, etc. CO2 laser tubes are generally suitable for small and medium-sized cutting machines, with power generally above 100W and better cutting effect; fiber lasers are commonly used in large cutting machines, with power generally above 1KW and fast cutting speed, suitable for materials with a thickness greater than 5mm.

Most Comprehensive Fiber Laser Cutting Parameters

Cutting head

The cutting head is mainly used to control the direction and focus of the laser beam, which affects the accuracy and focusing effect of the laser beam. Generally speaking, the cutting head is divided into ordinary cutting head and automatic welding cutting head. Common focusing lenses are F = 100mm and F = 200mm.

Lens

The lens is one of the important components of a laser cutting machine. It is mainly used to focus the laser beam on the working surface, affecting the focusing, energy density and cutting effect of the laser beam. Common lenses include lenses, mirrors, etc., generally including an output window mirror, a front mirror and a mirror.

Guide rail

Guide rails are an important part of affecting the accuracy and speed of laser cutting machines. Commonly used guide rails include linear guide rails and rolling guide rails. Linear guide rails are generally used for cutting machines with high precision requirements, and rolling guide rails are generally used for cutting machines with high speed requirements.

Laser cutting table

The laser cutting table is the carrying part of a laser cutting machine. It is generally divided into a fixed workbench and a lifting workbench. The former is suitable for cutting thin materials and processing plates, while the latter is suitable for processing thicker plates and pipes. The workbench materials are generally made of industrial materials such as steel plates and aluminum plates.

In summary, the configuration of a laser cutting machine includes important components such as laser source, cutting head, lens, guide rail, workbench, etc. Cutting tasks with different materials and process requirements require different configuration plans, and you need to carefully consider your own needs and budget before purchasing.

Types of Laser Cutting Machines

Laser cutting has different cutting methods for different materials, mainly divided into melt cutting, oxidation cutting, gasification cutting, and guide cutting.

Melt cutting: mainly for stainless steel, aluminum and other metal materials.

Oxidation cutting: carbon steel and other metal materials.

Gasification cutting: carbon materials, some plastics and wood, etc.

Guide cutting: porcelain.

Advanced laser cutting techniques

Precision cutting:

Laser cutting uses a laser beam for cutting, and its diameter can reach a small size, so it can achieve high-precision cutting. It can achieve cutting requirements as small as millimeters or even smaller, and is suitable for application fields with strict accuracy requirements on materials.

How Factors Affect Precision Laser Cutting Accuracy

Cutting speed:

Compared with the traditional cutting process, it is faster, improving work efficiency and saving labor.

Non-contact processing:

Without touching the processed material, the cutting is achieved by the irradiation and thermal action of the laser beam without mechanical force and deformation. This non-contact property makes laser cutting suitable for Industrial cutting fields with high material sensitivity, such as electronic devices, thin film materials, etc.

Small heat-affected zone:

The high-energy density laser beam locally heats and melts the material, and then blows the molten material off through a gas jet, thus achieving cutting. The heat-affected area is small, reducing thermal damage to the area around the material. Suitable for materials with higher heat sensitivity.

Narrow slit:

It can achieve a very small slit width, usually in the tens of microns or even smaller. It is suitable for fields that require high slit quality, such as precision machining and microelectronic device manufacturing.

Can process a variety of materials:

Laser cutting can not only cut metal materials, but also cut non-metallic materials such as plastics, wood, glass, etc. Different types of laser cutting machines can adapt to the cutting needs of different materials by adjusting the wavelength of the laser.

What Are the Laser Cutting Advantages and Disadvantages

Laser Cutting Techniques

Laser cutting is a processing method in which a high-power density laser beam irradiates a workpiece, causing the surface of the irradiated workpiece to rapidly melt or vaporize and vaporize at an extremely high speed, thus forming a cut.

Laser marking engraving is a method of using a laser beam to locally irradiate a material to melt or evaporate the surface of the material, thereby marking the surface of the material for a long time.

What materials can be cut with the laser?

Laser cutting machines include fiber laser cutting machines and carbon dioxide laser cutting machines that cut metal and non-metallic plates respectively.

Fiber laser cutting machines specialize in cutting metals. The more commonly cut materials include: stainless steel, carbon steel, alloy steel, aluminum plates, gold, silver, titanium and other metal materials.

CO2 laser cutting machine can cut cloth, wood board, plexiglass (acrylic), two-color board, leather, and plastic.

- Comprehensive Best Laser Cutting Materials List

- How to Set Laser Cutter Settings for Different Materials

Laser cutting technology vs traditional cutting

Laser cutting technology is an efficient, accurate and flexible cutting technology, which is very different from traditional cutting technology. There are some differences between Laser cutting method and traditional cutting technology, including accuracy, speed, cutting objects and materials, cutting lines and shapes, finished product quality, environmental protection and safety. Which Metal fabrication method to choose needs to be determined according to different cutting needs and material types.

Industrial applications of lasers

Laser cutting technology is developing towards smaller, thinner and more precise. Laser cutting has been widely used in Aerospace laser cutting, Automotive parts fabrication, Stainless steel cutting, Acrylic and wood laser cutting, Crafts production, Kitchen appliances and other fields, and has become one of the important means of transformation and upgrading of manufacturing industries at home and abroad.

What software is used for laser cutting

CAD drawings need to be drawn before laser cutting. As a representative of drawing software, CAD software is widely used. There are many CAD software on the market, mainly including:

1. AutoCAD: This is the most popular CAD software at present, with powerful drawing capabilities and a wide range of application fields. But the price is relatively high, suitable for professional users who need high-precision drawing.

2. SolidWorks: This is a 3D CAD software suitable for mechanical design and manufacturing. It has the advantages of reliability, accuracy and ease of use, and is widely used in industrial manufacturing.

3. CATIA: This is a 3D CAD software that provides solutions for manufacturing, design engineering and product lifecycle management. Fully functional and widely used, it is one of the software often used in the manufacturing industry.

After laser cutting, CAD drawings need to be converted into cutting codes, and post-processing software mainly plays such a role. Commonly used post-processing software includes:

1. FastCAM: This is a professional CNC cutting post-processing software that supports the import and export of multiple file formats, with powerful functions, easy to learn and use.

2. SheetCAM: This is a relatively inexpensive post-processing software suitable for mechanical manufacturing, laser cutting, water jet cutting and other fields. It has excellent vectorization, trust, accuracy and speed.

3. BobCAD-CAM: This is a low-cost, easy-to-learn and easy-to-use post-processing software that supports the import of multiple CAD formats, supports cutting path optimization, and a variety of preprocessing functions, suitable for 3D design and mechanical manufacturing.

Laser cutting process steps

- 1. Fix the cutting material. The material to be cut is fixed on the working surface of the laser cutting machine;

- 2. According to the material and thickness of the metal plate, adjust the equipment parameters accordingly.

- 3. Select the appropriate lens and nozzle, and check their integrity and cleanliness before starting.

- 4. Adjust the focus. Adjust the cutting head to the appropriate focus position;

- 5. Check and adjust the nozzle center.

- 6. Calibration of the cutting head sensor;

- 7. Select the appropriate cutting gas and check whether it is sprayed in good condition.

- 8. Try cutting the material. After cutting the material, check whether the cutting end face is smooth and check the cutting accuracy. If there are any errors, please adjust the equipment parameters accordingly until the requirements are met and proofreading can be achieved.

- 9. Program the workpiece drawings and make corresponding typesetting, and import them into the equipment cutting system.

- 10. Adjust the position of the cutting head and start cutting.

- 11. During the surgery, personnel should always be present and carefully observe the cutting. If an emergency occurs and a quick response is required, press the emergency stop button.

- 12. Check the cutting quality and accuracy of the first sample.

Safety in laser cutting

When operating a metal laser cutting machine, in addition to strictly following the operating procedures, personal protection should also be taken. For example, when near the laser beam, you must wear protective glasses that meet the requirements to avoid unnecessary risks. If you are a novice operating it, you must read all relevant instructions or get professional training before taking up the job. Do not use or operate it randomly.

- How To Avoid Fiber Laser Cutting Machine Accident

- Laser Cutter Safety Comprehensive Standards Guidelines

Alternatives to laser cutting technology

Plasma cutting technology

Plasma cutting technology is a commonly used sheet metal processing technology that can be used instead of laser cutting machines. By generating plasma on the metal surface to melt the material, cutting is achieved. Plasma cutting machines are characterized by high precision and wide application, and can cut metal sheets, pipes, and profiles of different thicknesses.

CNC shearing machine technology

Numerical control shearing machine is a kind of equipment that controls the cutting of steel plates through numerical control system. In the cutting process, the blade is used to cut the steel plate into the desired shape and size. The numerical control shearing machine is characterized by fast cutting speed and can cut steel plates of different thicknesses, but the accuracy is slightly lower than that of laser cutting machines.

Plasma cutting VS CNC shearing machine

Plasma cutting and numerical control shearing machine can replace the laser cutting machine, but in different application scenarios, its advantages and disadvantages are also different.

Plasma cutting machine is suitable for metal plates with a thickness greater than 20mm, and has more advantages than numerical control shearing machine when cutting metal plates with a larger thickness.

The numerical control shearing machine is suitable for cutting steel plates with a thickness of less than 20mm and a relatively simple shape, and is superior to the plasma cutting machine in terms of cutting speed.

Which One is Better, Laser VS Plasma Cutting?

How long does laser cutting metal take

Depends on the cutting speed of the laser cutting equipment and the cutting cost per square meter. Typically, a laser cuts a plate with a thickness of 6mm, and the cutting speed is about 1-2 meters per minute. Therefore, the cutting time of 1 square meter takes about 30-60 minutes. For the cutting cost, different equipment and service providers will vary.

Laser cutting machine maintenance

The use of a laser cutting machine for a period of time, due to the smoke and dust generated by cutting, has a corrosive effect on the guide rail, so scientific maintenance of the laser cutting machine can not only avoid some minor faults, improve cutting efficiency, but also improve the service life of some accessories.